Variable frequency and jet flow oscillator

An oscillator and jet technology, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, mechanical equipment, etc., can solve the problems of unstable working frequency and inability to adjust

Active Publication Date: 2013-03-13

NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, for the jet oscillators that have been maturely used at present, the switching frequency of the main jet oscillation is determined by the structure of the jet element itself and the structure of the feedback loop. The working frequency is not stable enough in use, and it cannot be adjusted according to the actual working conditions.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

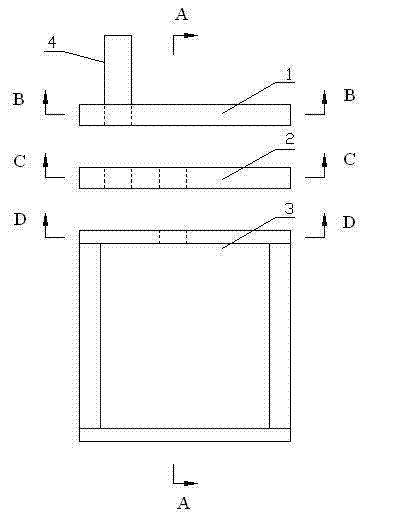

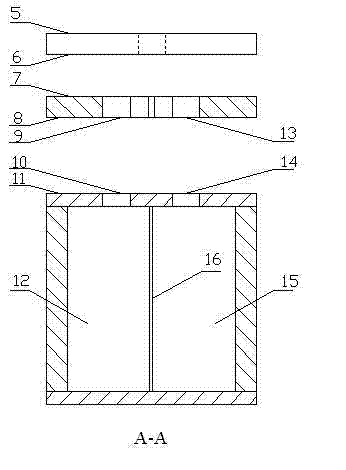

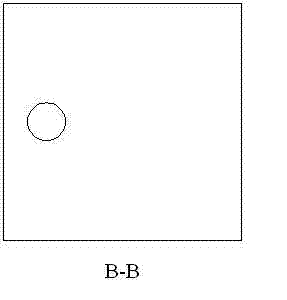

The invention discloses a variable frequency and jet flow oscillator which is used for controlling the high-frequency switching of jet flow in different pipelines. The upper end face of a single-film double-cavity vibration exciter is in parallel fit with the lower surface of an oscillation jet flow component, and the upper surface of the oscillation jet flow component is in parallel fit with the lower surface of a cover plate; the upper surface of the cover plate is provided with an inlet passage; an oscillation jet flow component cusp is arranged between a first outlet passage and a second outlet passage on the oscillation jet flow component; a vibrating membrane vertical to the upper end face in the single-film double-cavity vibration exciter; the single-film double-cavity vibration exciter is divided into a first cavity and a second cavity through the vibrating membrane; the first cavity is provided with a first cavity inlet; the second cavity is provided with a second cavity outlet; and the first cavity outlet, and the second cavity outlet are connected with a first control port and a second control port of the oscillation jet flow component respectively. The working frequency of the jet flow oscillator is actively controlled by changing the excitation frequency of the oscillator and the adjusted working frequency is stable and reliable.

Description

technical field [0001] The invention relates to a frequency-variable jet fluid oscillator, which is used to control the high-frequency switching of jet fluid in different pipelines. Background technique [0002] The jet oscillator uses fluid as the working medium, and uses the wall attachment effect of the main jet in a chamber of a specific shape to work. The oscillation switching of the jet can be realized without relying on any mechanical moving parts inside the oscillator, and it can be combined with mechanical or electronic components, etc. Compared with other actuators, the jet oscillator has the advantages of low cost and good reliability, and is widely used in machinery manufacturing, drilling equipment, petrochemical and other fields. However, in the jet oscillators that have been maturely used at present, the switching frequency of the main jet oscillation is determined by the structure of the jet element itself and the structure of the feedback loop. The working ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F15B21/12

Inventor 顾蕴松吕为程克明

Owner NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com