Crimping radio frequency coaxial connector

A radio frequency coaxial connector technology, applied in the direction of connection, two-part connection device, connection with permanent deformation, etc., can solve thread slippage, affect the crimping firmness of radio frequency coaxial connector and transmission cable, reduce Problems such as the fastening force of the connecting sleeve and the connecting inner sleeve, etc., achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Implementation details of the present invention are described as follows in conjunction with accompanying drawing:

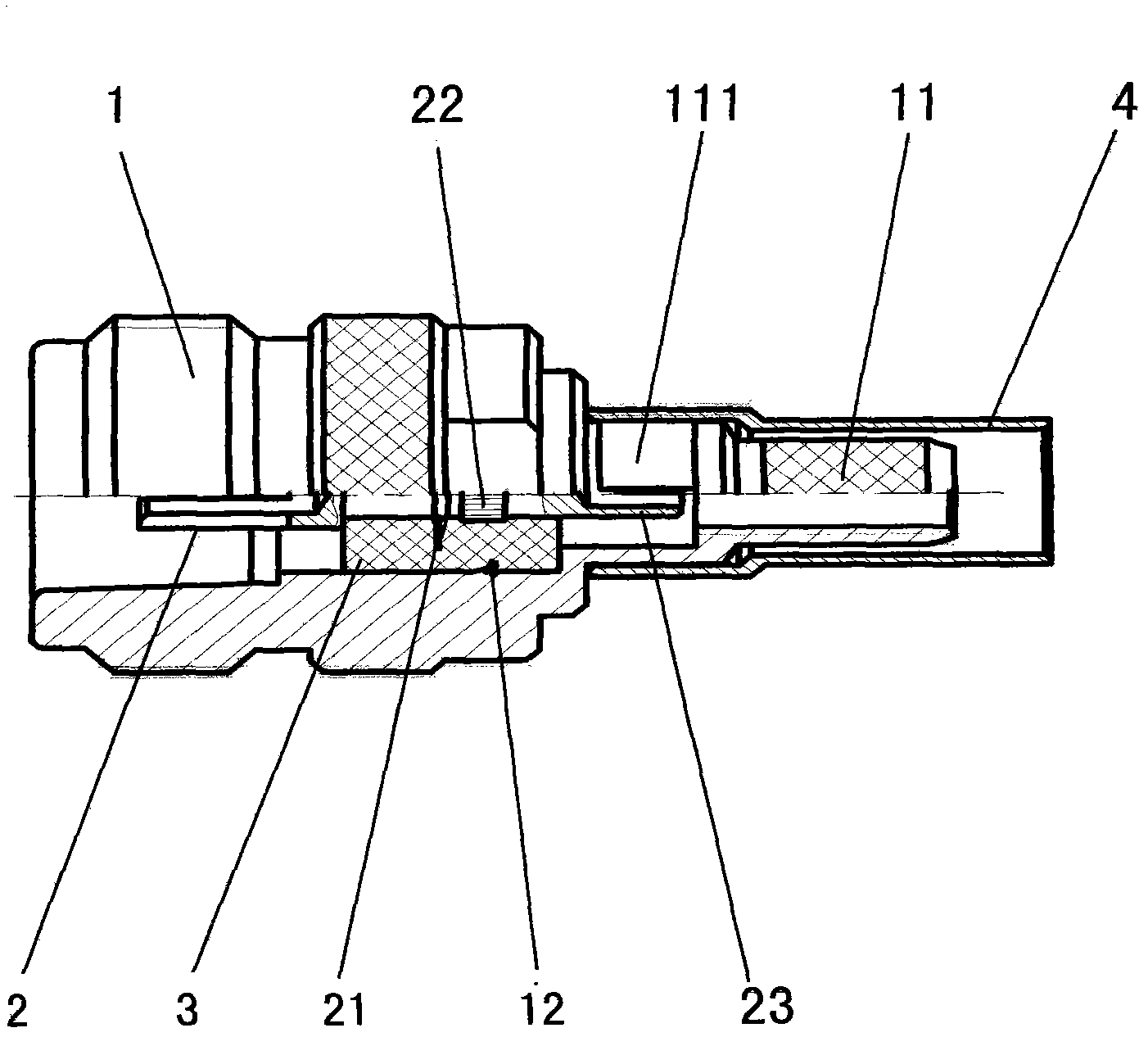

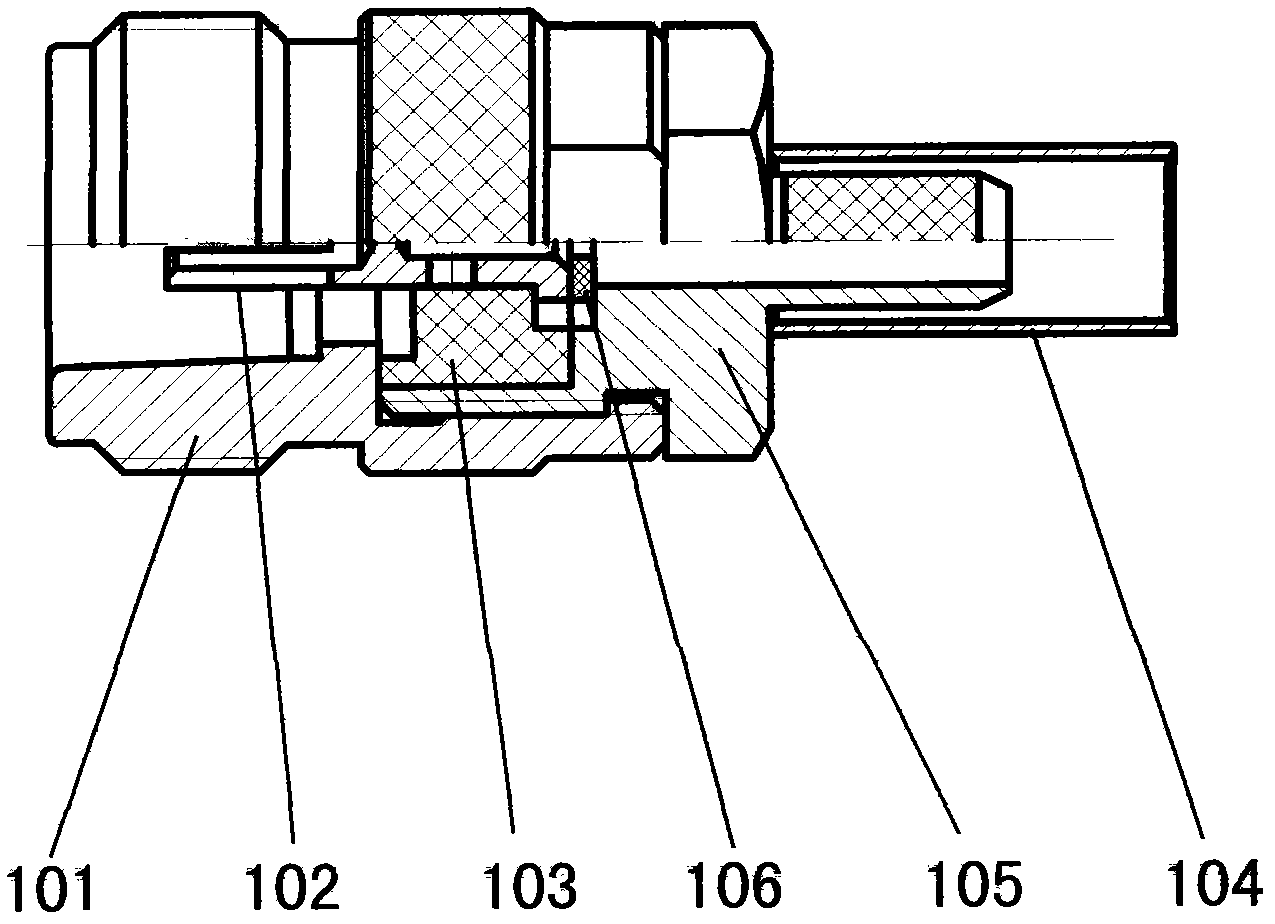

[0017] like figure 1 , 7 As shown in , 8, a crimping type radio frequency coaxial connector, including the connecting sleeve 1 provided with connecting threads and ring-shaped reticulated protrusions on the shell of the connecting end, the plug-in end and the welding end are all in the shape of tube holes. The conductor 2 is sleeved outside the inner conductor and the insulating sleeve 3 embedded in the inner cavity of the connecting sleeve, and the crimping sleeve 4 for crimping the cable is characterized by

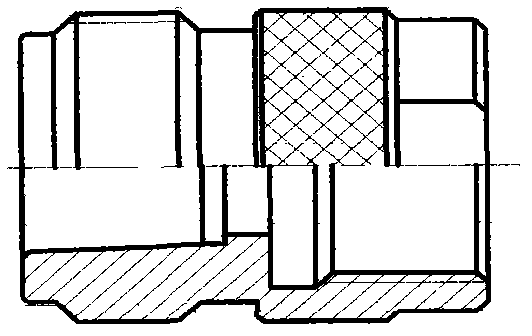

[0018] ——The crimping end of the connecting sleeve is designed to be integrated with the connecting sleeve body, and has a stepped tubular crimping head 11 with a larger neck outer diameter and a smaller head outer diameter;

[0019] - The neck of the tubular crimping joint of the connecting sleeve is designed with a welding operation window 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com