Pulse water flow forming system driven by hydraulic power of fountain and surf

A water-driven, surfing technology, applied in jetting devices, liquid jetting devices, etc., can solve problems such as threats to personal safety, difficult maintenance and complex structures, and achieve low investment costs, simple structures, and good safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

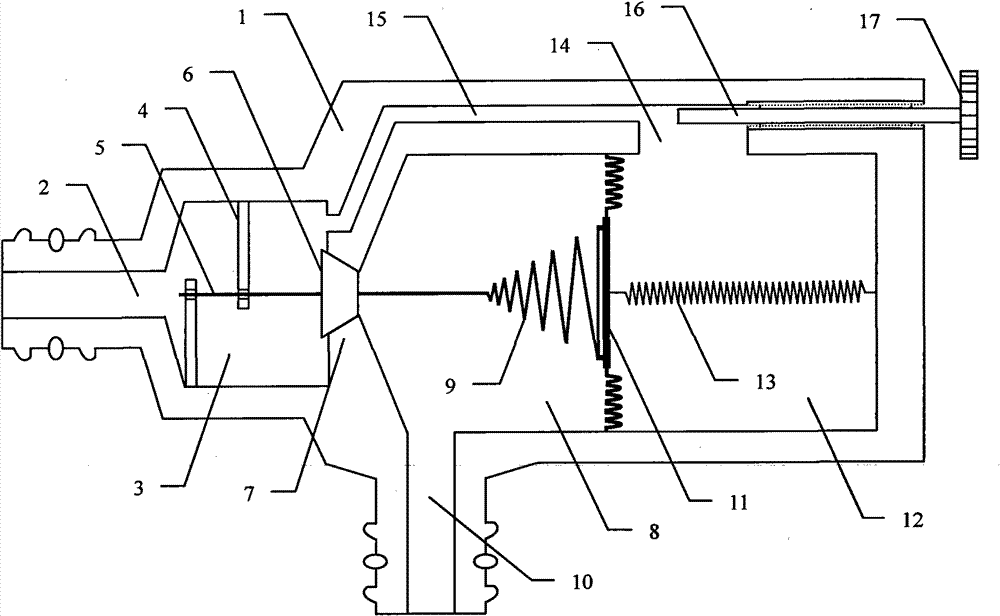

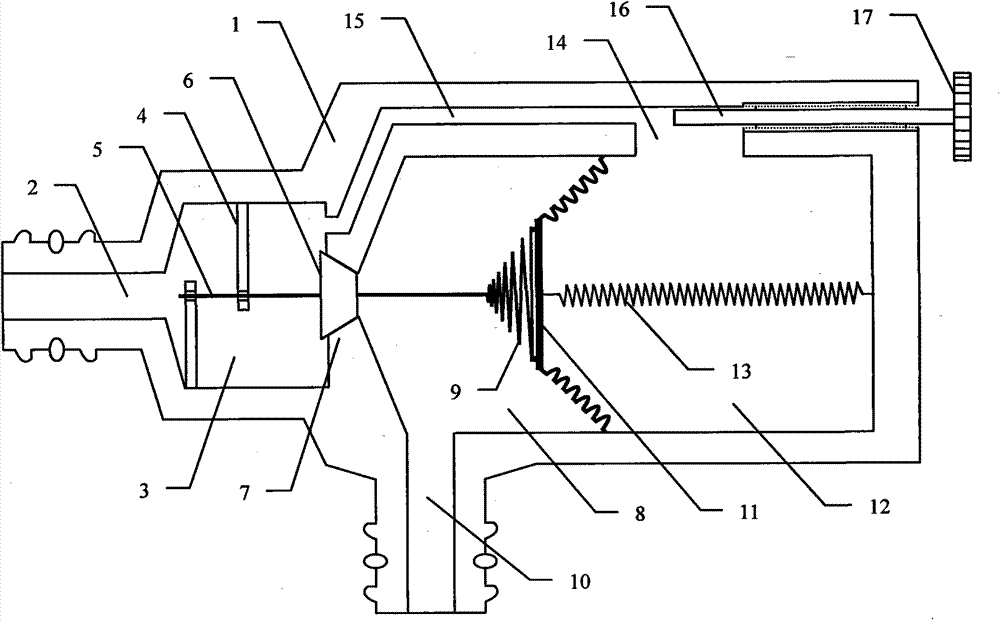

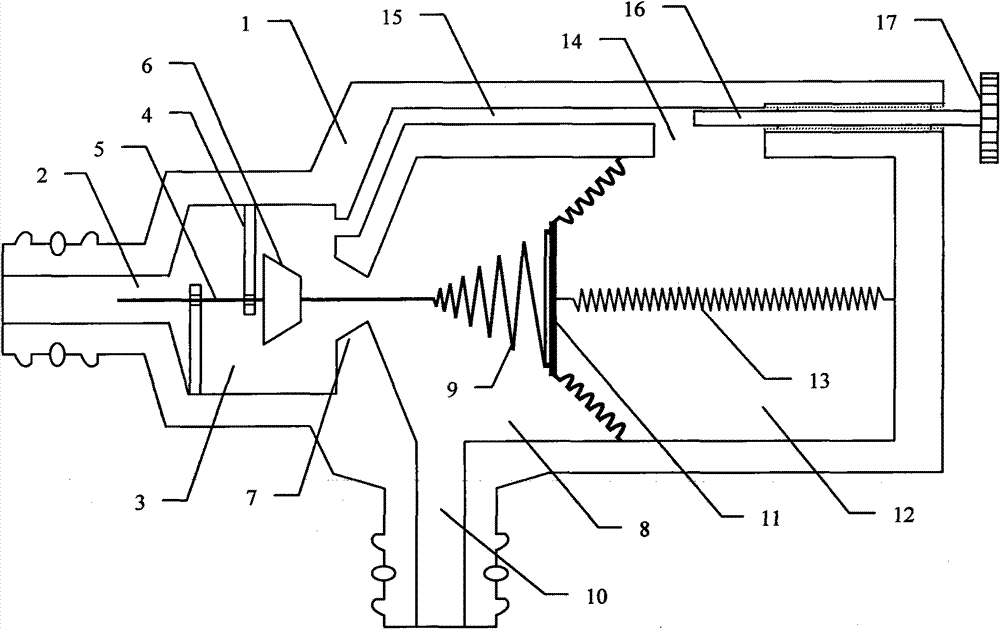

[0022] A fountain, surfing hydraulic driving pulse water flow forming system, including: water source, water pump, main pipe, air pressure storage tank, branch pipe, pulse valve, capillary, nozzle (nozzle), the water inlet of the water pump is connected with the water source, and the water outlet of the water pump Connected to the main water inlet, the main water outlet is connected to several branch pipes through the air pressure storage tank, the branch pipe is connected to several capillary pipes through several pulse valves, the water inlet of the pulse valve leads to the branch pipe, and the water outlet of the pulse valve leads to Capillary tubes, each capillary tube is equipped with one set or one nozzle (nozzle). The air pressure accumulator tank is a sealed tank with a certain pressure bearing capacity. The top of the air pressure accumulator tank is equipped with a safety relief valve, and the air pressure accumulator tank enters and exits. The water pipes are located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com