Washing method applied to dishwasher

A dishwashing machine and cleaning liquid technology, which is applied in applications, tableware washing machines/rinsing machines, household cleaning devices, etc., can solve problems such as poor cleaning effect, small water spraying force, and small water spraying volume, and achieve water flow strength Strong, large water flow, less water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

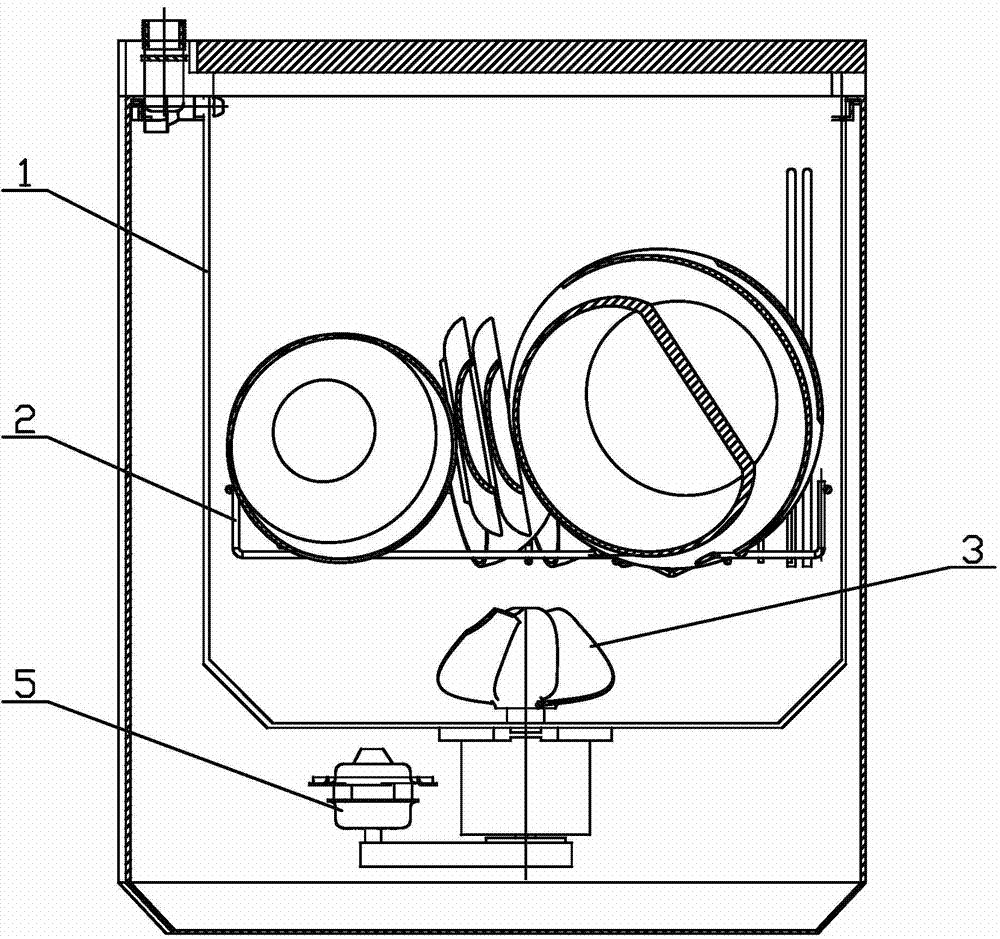

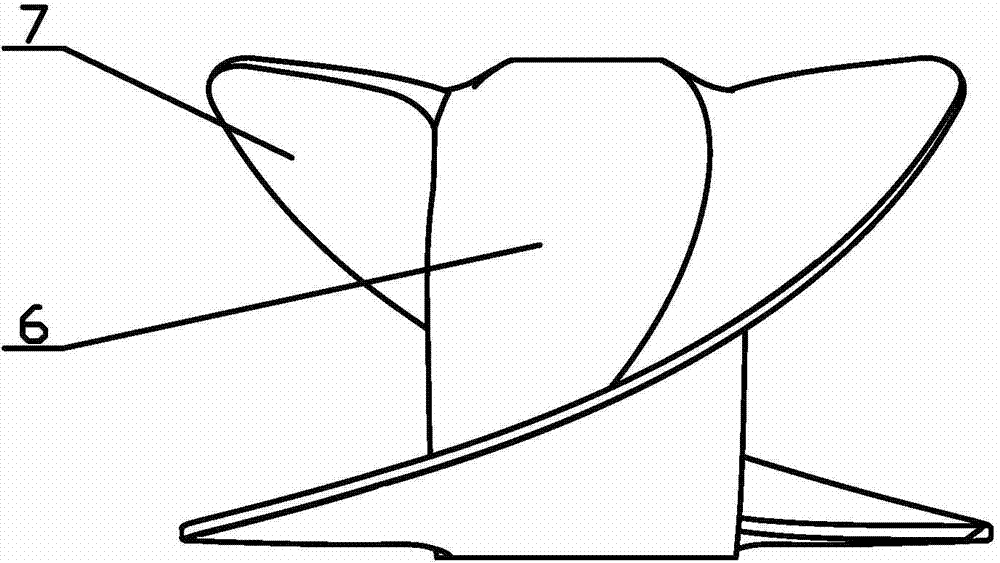

[0029] The structure of a dishwasher provided in this embodiment is as follows: figure 1 As shown, it includes a box body 1 and a dish rack 2, and a screw propeller 3 is installed at the bottom of the box body 1, and the tableware that needs to be cleaned is placed on the dish rack 2, and the screw propeller 3 is connected to the drive mechanism, so The drive mechanism is composed of a motor and a speed change mechanism. In this embodiment, the motor drives the shaft where the screw propeller 3 is located to rotate through a pulley, and a combination of a motor and a gear box or a variable frequency motor can be used to propel the screw directly. The speed of the device 3 is controlled. The structure of the screw propeller 3 is as figure 2 As shown, by the axial rotation part 6, two helical blades 7 are arranged axially on the outer periphery of the axial rotation part 6, and it can also be a plurality of blades. Its function is to push the cleaning liquid from the bottom to...

Embodiment 2

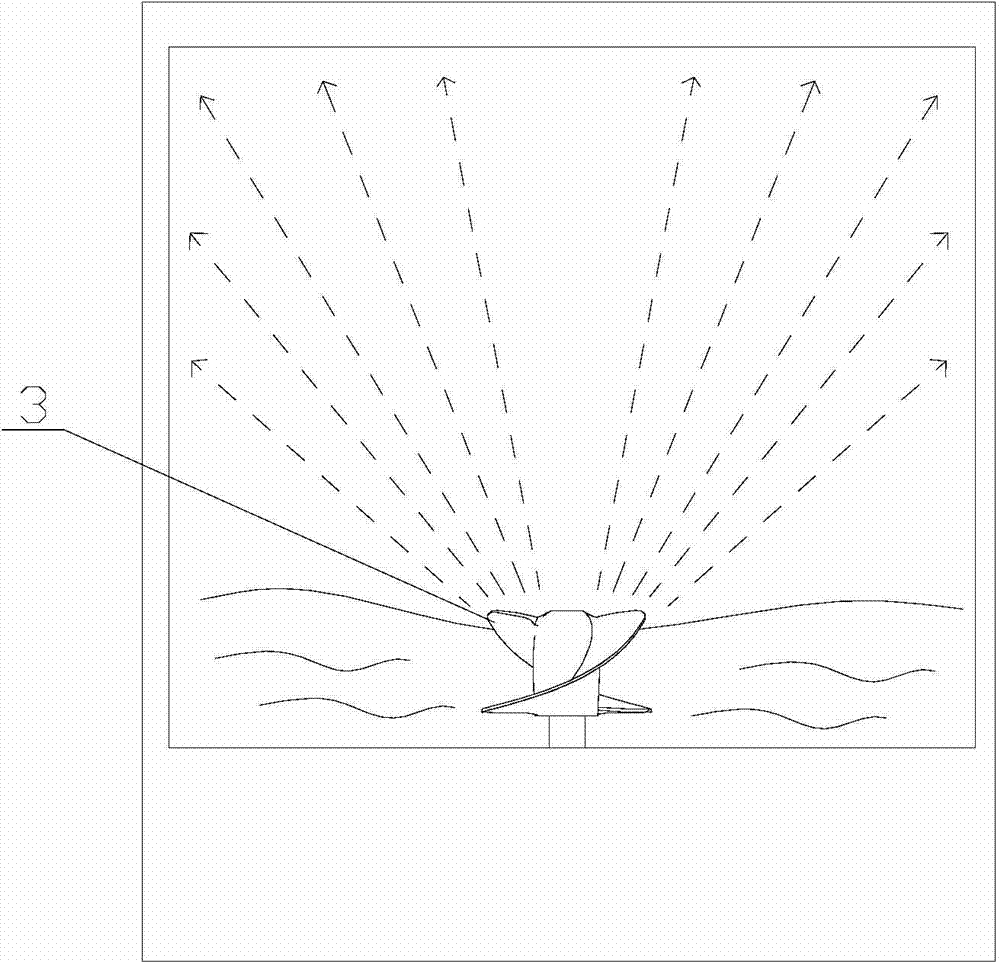

[0033] As another kind of dishwasher, its structure is as follows Figure 4 As shown, compared with Example 1, the difference is that the cleaning device used is equipped with a flow-restricting ring 4 around the corresponding screw propeller 3, and the flow-restricting ring 4 can change and limit the outer surface of the washing liquid. Direction of injection to make water flow more concentrated or change its flow direction for stronger washing effect.

[0034] The cleaning method used in the dishwasher, its corresponding action principle is as follows: Figure 5 As shown, when the screw propeller 3 at the bottom rotates, it pushes the cleaning liquid where it is located to move upward from the bottom while assisting to produce a certain effect of splashing. The effect of the washing liquid on the edge changes the direction, thereby forming a more concentrated continuous high-speed external jet flow to clean the tableware placed on the top, especially suitable for dishwashin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com