Fine radiator

A radiator and slim technology, which is applied in the layout of power unit cooling combination, power unit, transportation and packaging. The effect of reducing the height of the guard plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

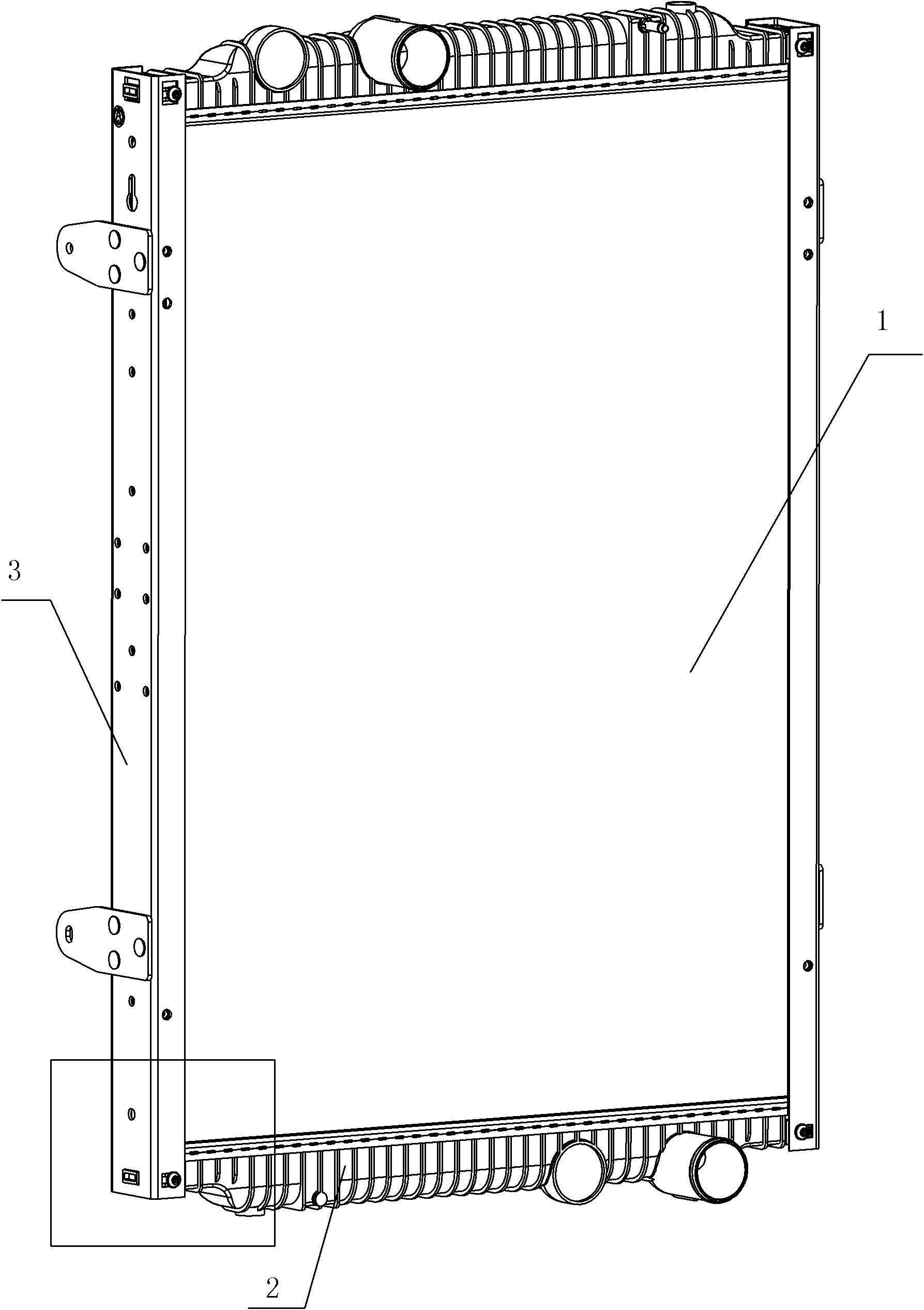

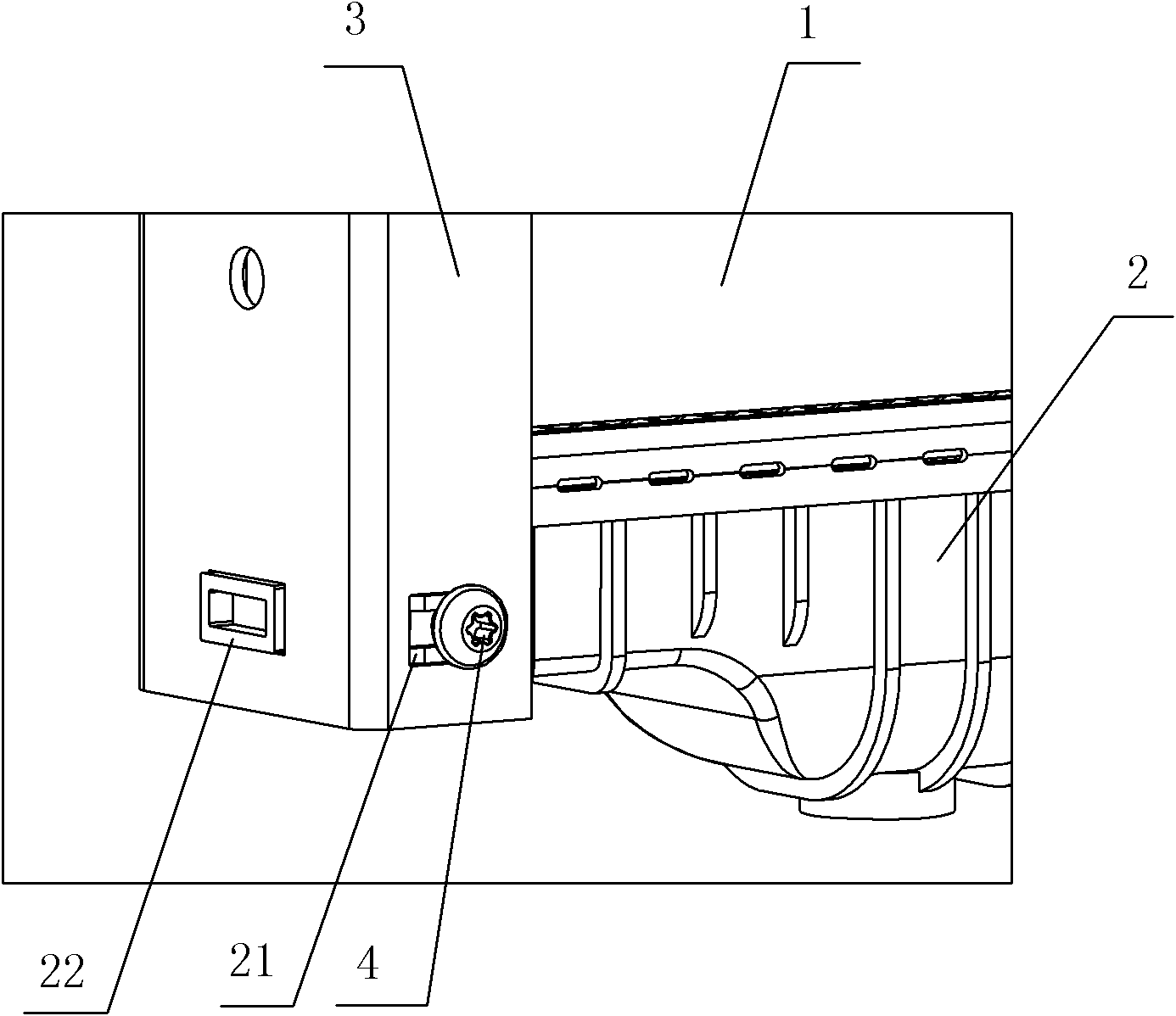

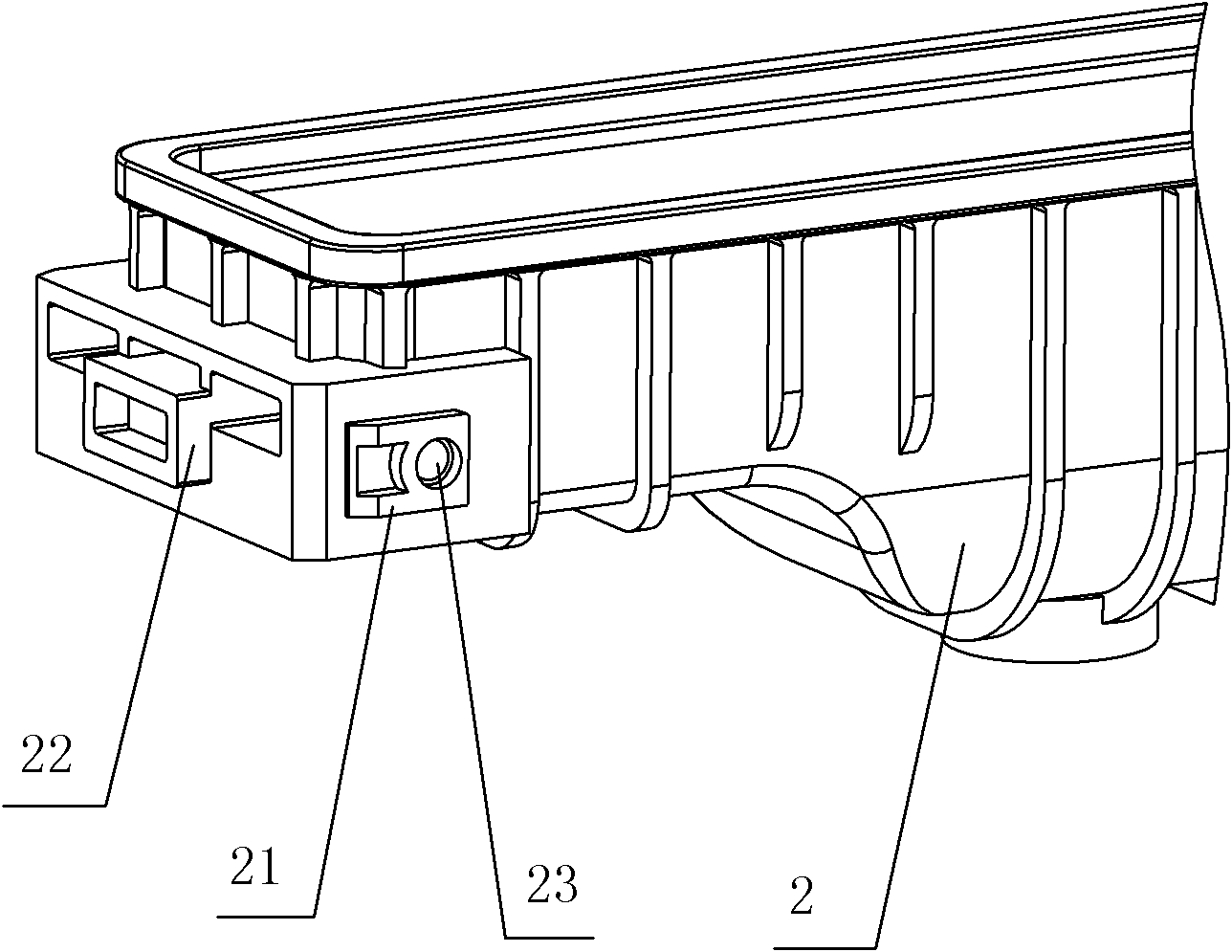

[0011] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a slender radiator includes a radiator core 1, a water chamber 2 fixed on the upper and lower ends of the radiator core 1, and guard plates 3 fixed on both sides of the water chamber 2 by screws 4. The ends of the water chamber 2 The front portion, the rear portion and the side are respectively provided with a front boss 21, a rear boss and a side boss 22, and the front boss 21 and the rear boss are also provided with screw mounting holes 23; Both ends of the guard plate 3 are respectively provided with square holes 31 corresponding to the front boss 21, the rear boss and the side bosses 22; the front boss 21 and the rear boss are respectively provided with chamfers.

[0012] Since the screw mounting holes 23 are integrated on the front boss 21 and the rear boss, the width of the water chamber 2 and the guard plate 3 can be adjusted to 70mm, so that the weight of the radiator can be reduced by more than 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com