Timing system driven pressurization system and adjustable pressurization method

A technology of timing system and supercharging system, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of complex and uncompact transmission structure, unsatisfactory driving power source of supercharging system, etc., and achieve the reduction of length , energy saving, compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

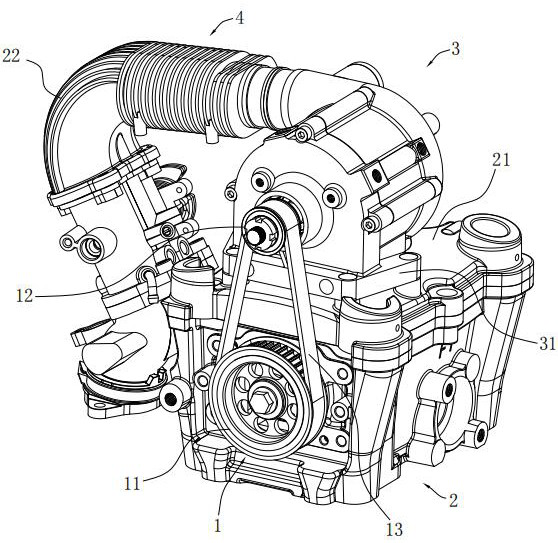

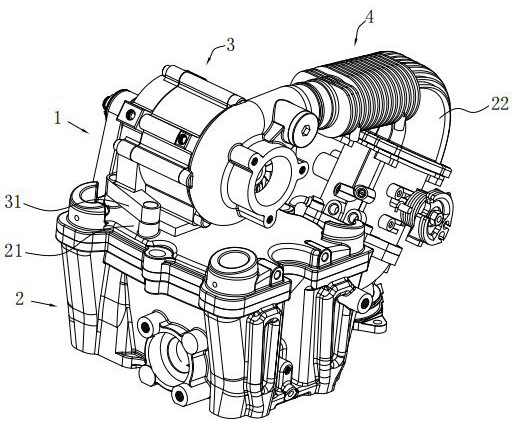

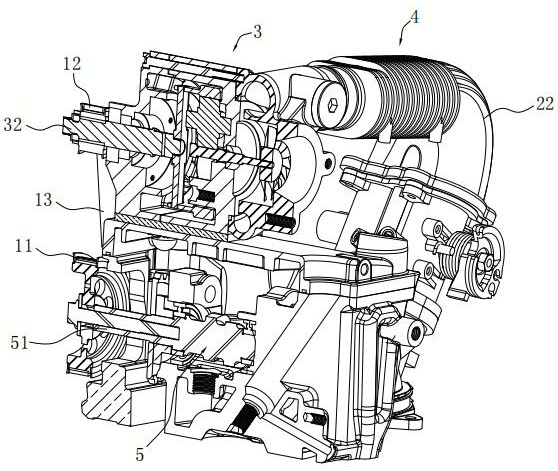

[0051] see figure 1 and figure 2 As shown, a schematic diagram of a supercharging system driven by the timing system 5 is disclosed. The supercharging system includes a cylinder 2 and a supercharger 3 , the cylinder 2 is provided with a cylinder cover 21 , the supercharger 3 is provided with a frame 31 , and the supercharger 3 is fixedly installed on the cylinder case 21 through the frame 31 . A transmission mechanism 1 is connected between the power output end of the cylinder 2 and the power input end of the supercharger 3 , and the transmission mechanism 1 transmits the torque of the power output end of the cylinder 2 to the power input end of the supercharger 3 . The transmission mechanism 1 includes a driving wheel assembly 11 and a driven wheel assembly 12, a transmission belt 13 is connected between the driving wheel assembly 11 and the driven wheel assembly 12, the driving wheel assembly 11 is connected with the power output end of the cylinder 2, and the driven wheel...

Embodiment 2

[0056] see Image 6 and Figure 7 As shown, the difference from the first embodiment is that the driving wheel assembly 11 and the driven wheel assembly 12 are V-shaped friction wheels, the positioning driven wheel 121 of the driving wheel assembly 11 is fixedly connected with the power output mechanism 51, and the variable driving wheel 112 is connected with the power The output shaft of the output mechanism 51 is connected by splines, the output shaft is designed as a spline, and the driving wheel assembly 11 is designed as a spline groove matched with the output shaft. The driving wheel assembly 11 can transmit the power of the power output mechanism 51 and the variable driving wheel 112 It can move along the axial direction of the power output mechanism 51 . The positioning driven wheel 121 of the driven wheel assembly 12 is fixedly connected with the input shaft 32 , the variable driven wheel 122 and the input shaft 32 are also connected by splines, the input shaft 32 is...

Embodiment 3

[0063] see Figure 8 to Figure 10 As shown, the difference from the above embodiment is that the supercharging system also includes an auxiliary fuel supply component, and the auxiliary fuel supply chamber of the auxiliary fuel supply component is used to store gasoline, and the gasoline can enter the air inlet through the fuel injection pipe, thereby increasing the intake air. At the same time, the ratio of gasoline in the air is increased to increase the utilization of oxygen in the air and ensure the power of the engine.

[0064] An outer ring gear 72 is fixedly connected to the peripheral side wall of the turbine 33, the auxiliary oil supply chamber is located on one side of the supercharging cover, and is fixedly connected to the engine cover through bolts. The auxiliary fuel supply chamber is filled with gasoline. The auxiliary oil supply chamber is provided with an oil filling hole (not shown in the figure) and a plug cover (not shown in the figure) that is detachably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com