Elevator device

A technology for elevators and motors, which is used in elevators, transportation and packaging in buildings, and can solve problems such as poor environmental load, larger volume, and larger equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

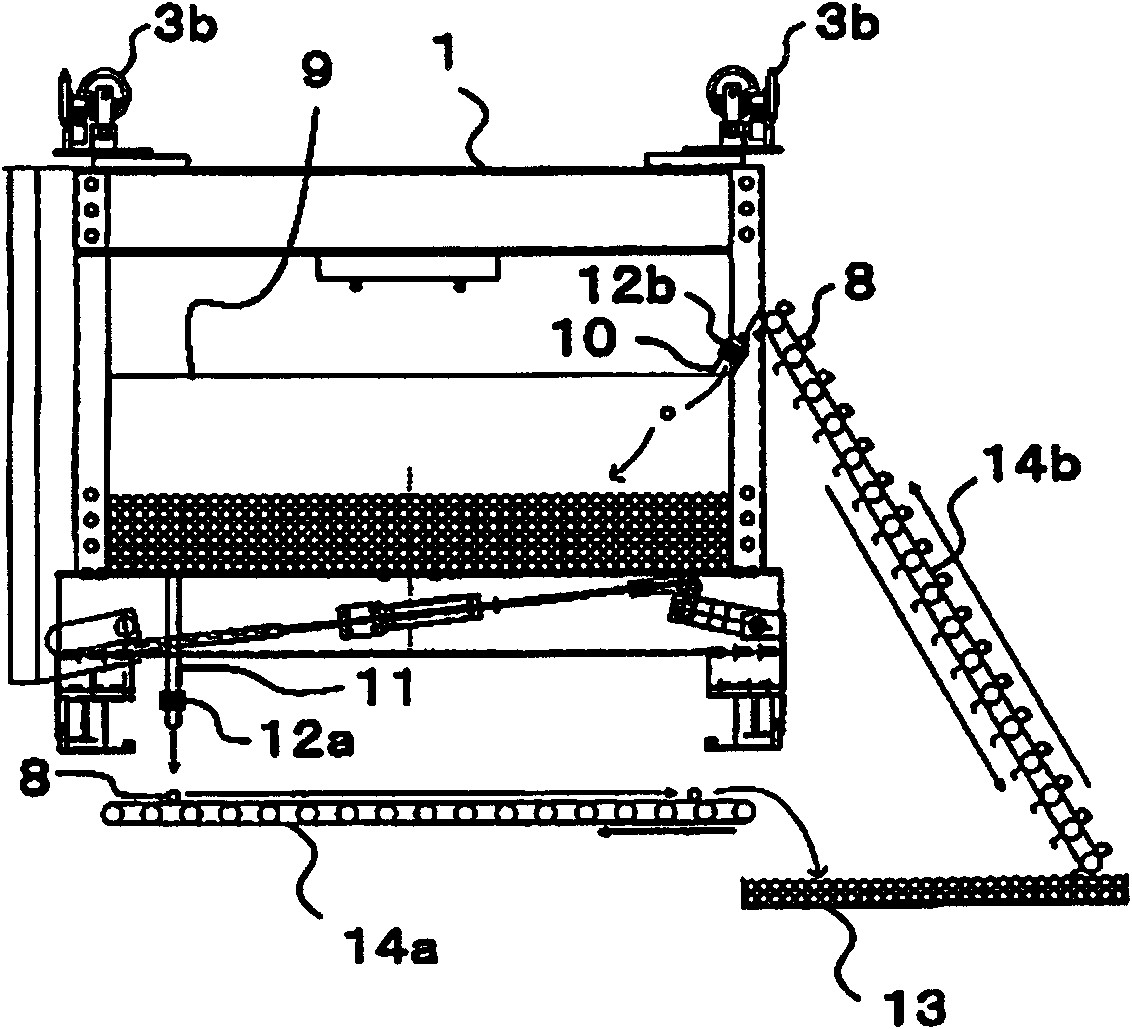

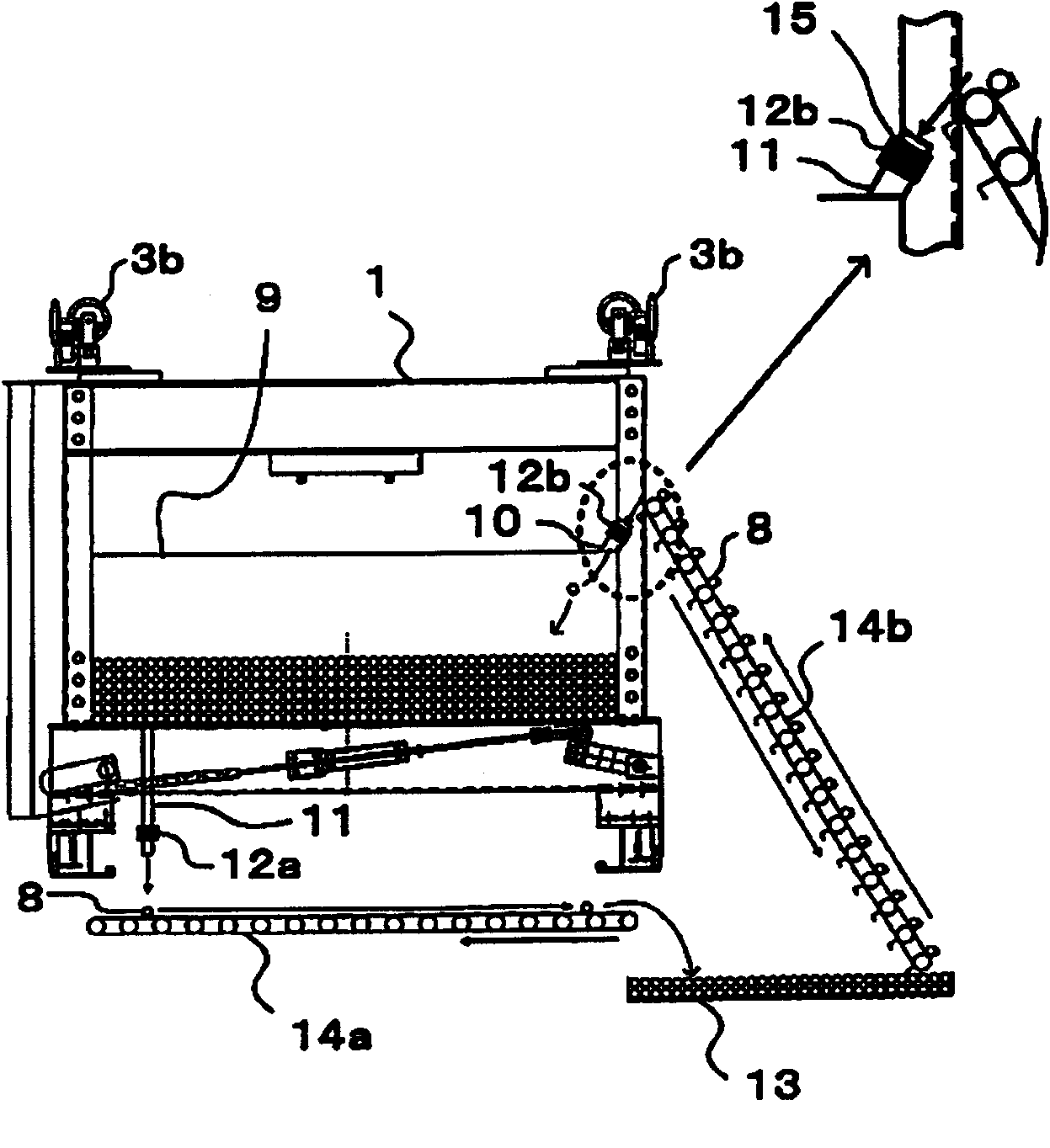

[0049] Hereinafter, embodiments of the elevator apparatus of the present invention will be described in detail with reference to the drawings. In addition, the Example described below is just an Example of this invention, and of course this invention is not limited to these.

[0050] The elevator device of the present embodiment is composed of a bucket type elevator device and an automatic weight adjustment device.

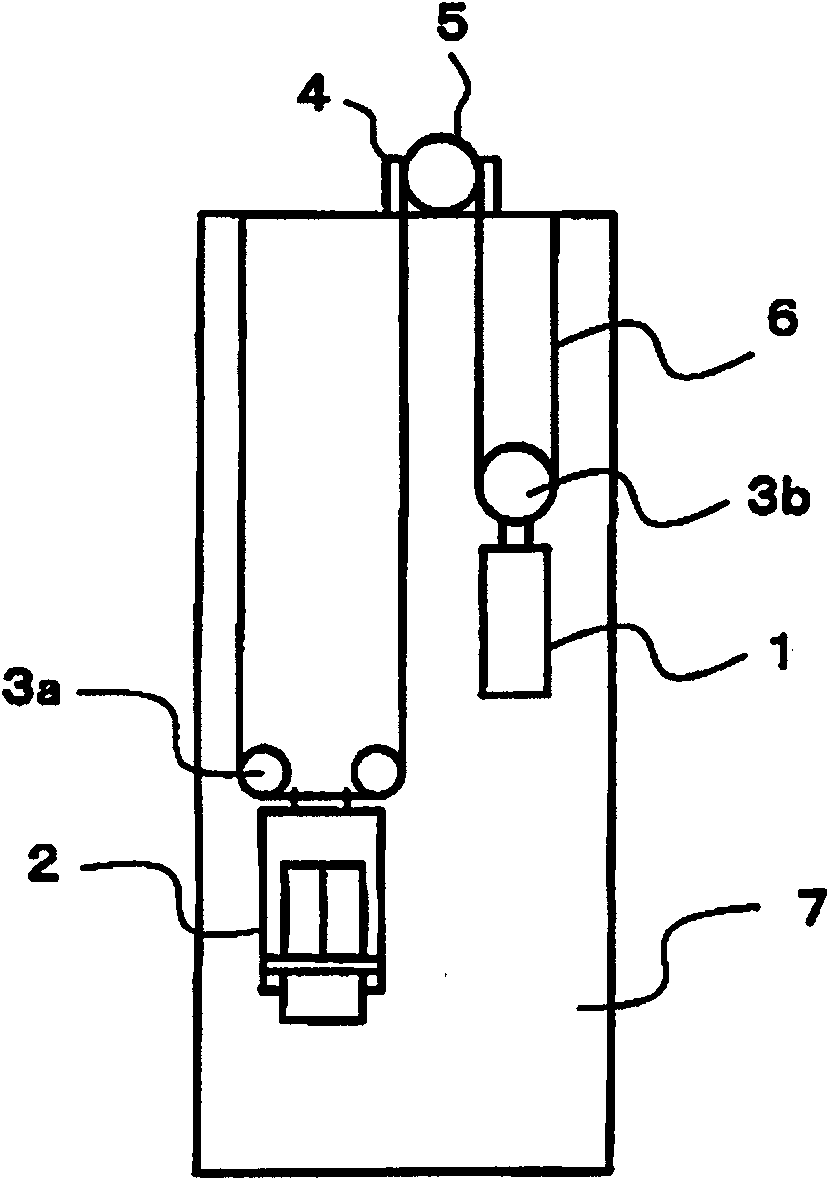

[0051] like figure 1 As shown, the bucket elevator device of the present embodiment consists of a counterweight 1, a car 2, and suspension wheels 3a, 3b respectively installed on the top of the counterweight 1 and the car 2, and a driving sheave 5 equipped in the hoisting machine 4. , main rope 6 and hoistway 7 constitute. One end of the main rope 6 is fixed on the top of the hoistway 7, and is drawn around in the order of the hanging sheave 3a of the car 2, the driving sheave 5, and the hanging sheave 3b of the counterweight 1, and the other end is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com