Solar heat collection automatic gradient phase change heat storage energy gradient utilization device

A technology of solar heat collection and phase change heat storage, which is applied in the field of solar energy utilization and phase change heat storage, can solve problems such as overheating of phase change materials, excessive solar heat energy, automatic adjustment of phase change material quality and heat storage temperature, etc., to achieve Improve the utilization rate and ensure the effect of heat storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

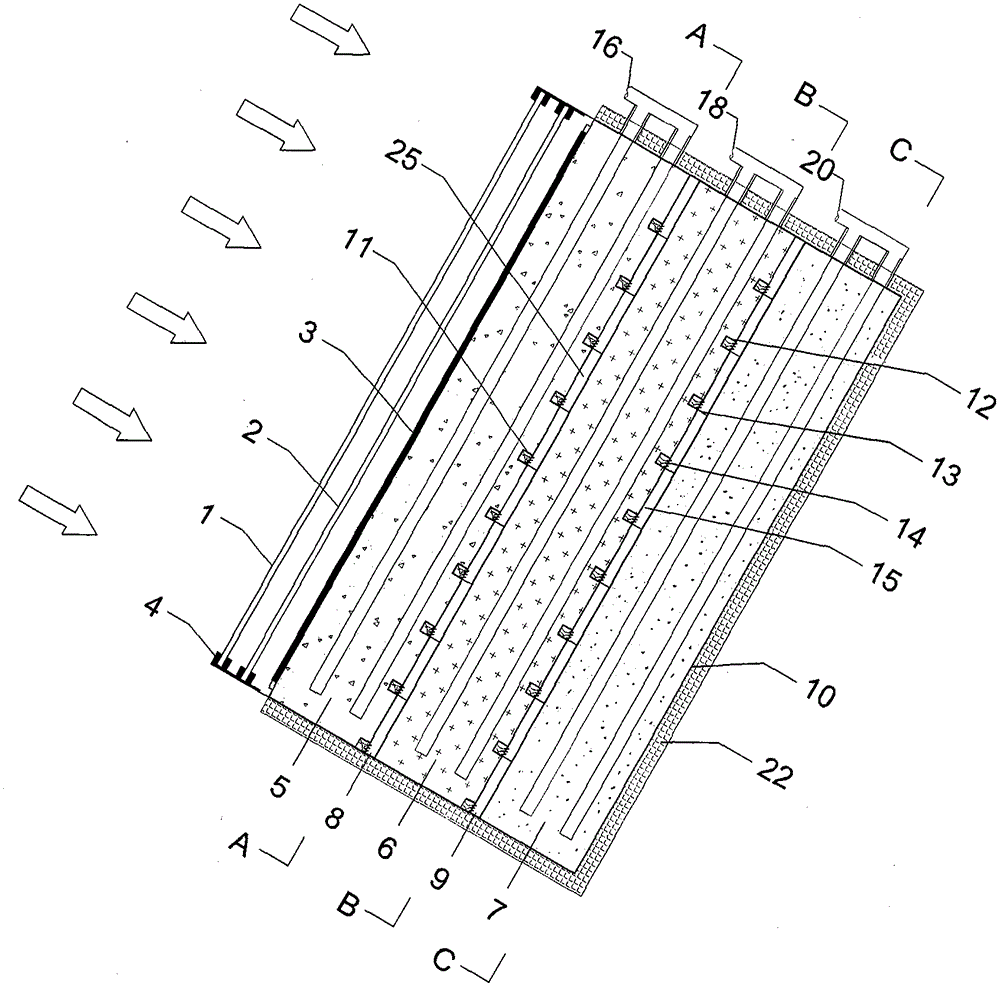

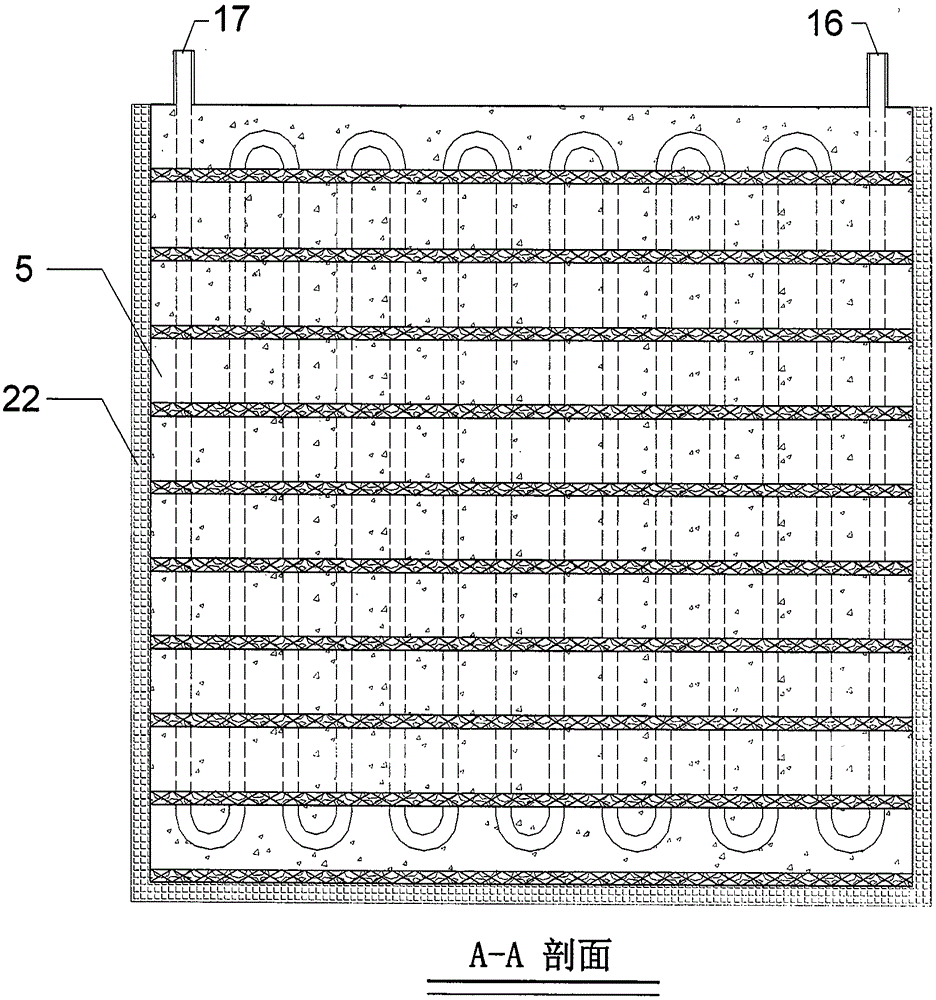

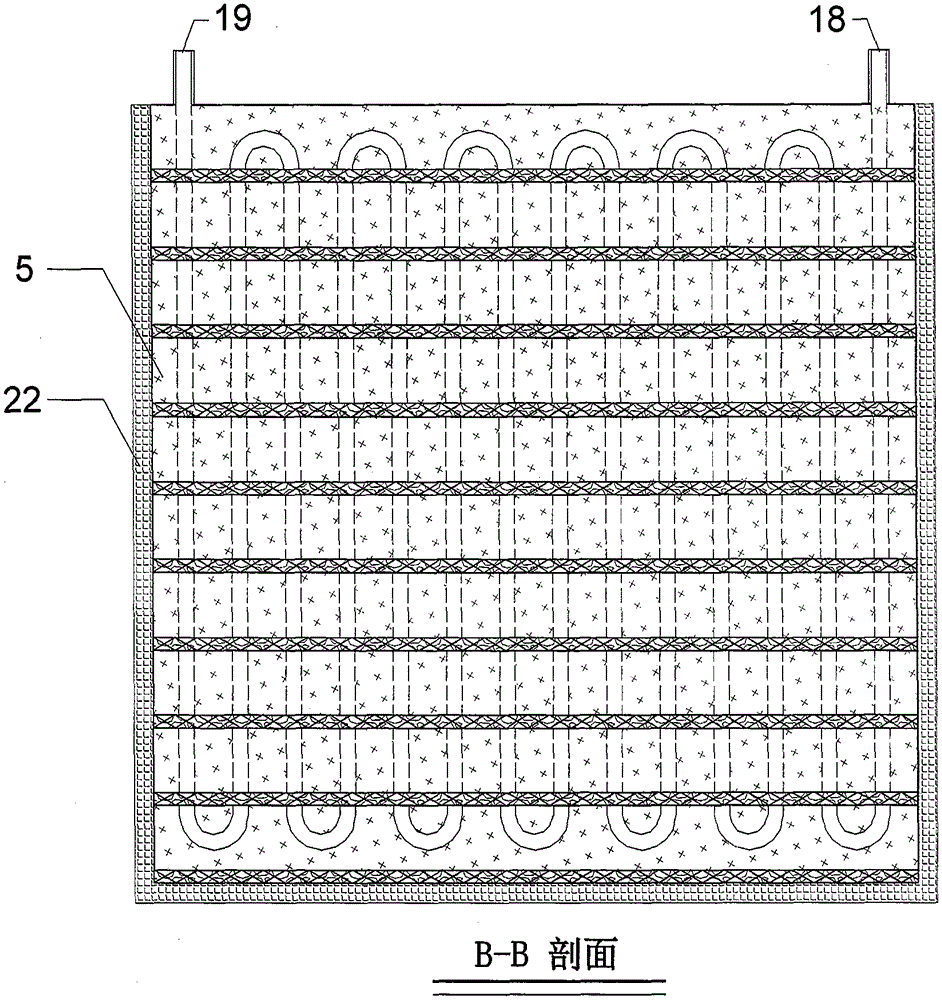

[0033] as attached figure 1 As shown, the solar heat collection automatic cascade phase change heat storage energy cascade utilization device includes: outer glass 1, inner glass 2, selective absorption film 3, fixed bracket 4, high temperature phase change heat storage layer 5, automatic Heat conduction layer 8, medium temperature phase change heat storage layer 6, automatic heat conduction layer 9, low temperature phase change heat storage layer 7, high temperature adsorption chamber 11, low temperature adsorption chamber 12, baffle plate 13, ventilation net 14, steam chamber 15, steam chamber 25 , water inlet pipe 16, water outlet pipe 17, water inlet pipe 18, water outlet pipe 19, water inlet pipe 20, water outlet pipe 21, housing 10, insulation layer 22, and the automatic heat conduction layer 8 is located at the high temperature phase change heat storage layer 5 and the medium temperature phase Between the variable heat storage layers 6, the automatic heat conduction lay...

Embodiment 2

[0036] The main difference between Example 2 and Example 1 lies in the arrangement of the phase-change heat storage layer and its automatic heat-conducting layer adsorption chamber. In Example 2, the integrated phase-change heat storage layer in Example 1 is replaced by a combined phase-change heat storage layer. heat storage layer, and the low thermal conductivity baffle plate 13 is cancelled, and other structural settings are the same. like Figure 5 As shown, in the weather with strong solar radiation, after the selective absorption film 3 absorbs sunlight, the temperature rises to directly heat the high-temperature phase-change thermal storage layer 5, and the high-temperature phase-change thermal storage layer 5 in the high-temperature phase-change thermal storage layer 5 The temperature change material gradually heats up and undergoes a phase change. After the high temperature phase change material reaches the phase change temperature, the high temperature adsorbent in t...

Embodiment 3

[0038] The main difference between embodiment 3 and embodiment 1 lies in the automatic adjustment method of the automatic heat conduction layer. In embodiment 3, the expansion ribs 23 are used to replace the adsorption chamber 11, adsorption chamber 12, baffle plate 13, air mesh 14, The steam chamber 15 and the steam chamber 25 have the same configuration as other structures. as attached Figure 7 As shown, the fins located in the automatic heat-conducting layer 8 are embedded in the high-temperature phase-change heat storage layer 5, and are at a certain distance from the medium-temperature phase-change heat storage layer 6 at low temperature; the expansion fins located in the automatic heat-conducting layer 9 are embedded in the medium-temperature In the phase change heat storage layer 6, there is a certain distance from the low temperature phase change heat storage layer 7 at low temperature. In the weather with strong solar radiation, after the selective absorption film 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com