Civil energy and heat storage system and method based on ettringite

A heat storage system and ettringite technology are applied in the field of civil energy storage and heat storage systems based on ettringite, and can solve the problems of high cost of energy storage units, poor heat storage/release effect, and being susceptible to external influences, etc. Achieve the effect of reducing carbon emissions, easy phase transition conditions, and ensuring heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

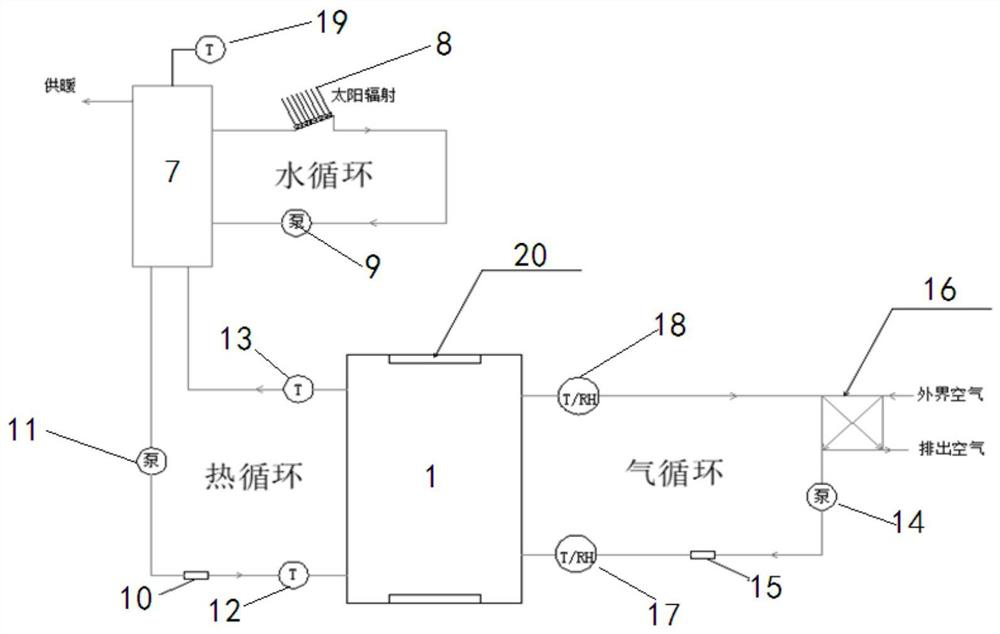

[0039] In a typical embodiment of the present invention, as Figure 1-Figure 6 As shown, a civil energy storage and heat storage system based on ettringite is proposed, including an energy storage chamber 1, a water circulation system, a thermal circulation system and an air circulation system.

[0040] The three circulation systems exist independently. The energy storage chamber 1 is connected with the thermal circulation system and the gas circulation system respectively through pipes, and the water circulation system is connected with the pipes of the thermal circulation system.

[0041] Among them, there are multiple energy storage chambers 1, and each energy storage chamber 1 is correspondingly provided with a thermal cycle system and a gas cycle system, and the thermal cycle system and the gas cycle system among the multiple energy storage chambers 1 do not affect each other, that is, : The thermal circulation system and gas circulation system of each energy storage cham...

Embodiment 2

[0083] In another typical embodiment of the present application, a method for using a civil energy storage and thermal storage system based on ettringite as described in Embodiment 1 is provided, as follows:

[0084] 1) Prepare, assemble and inspect the device;

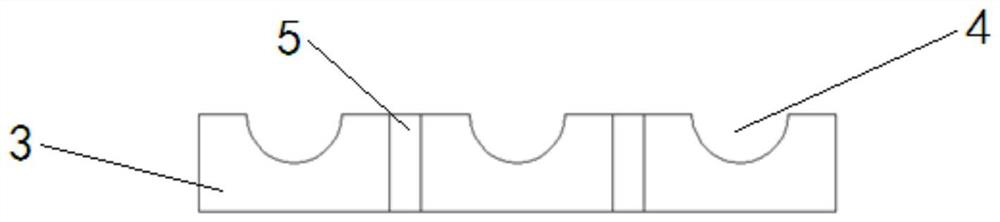

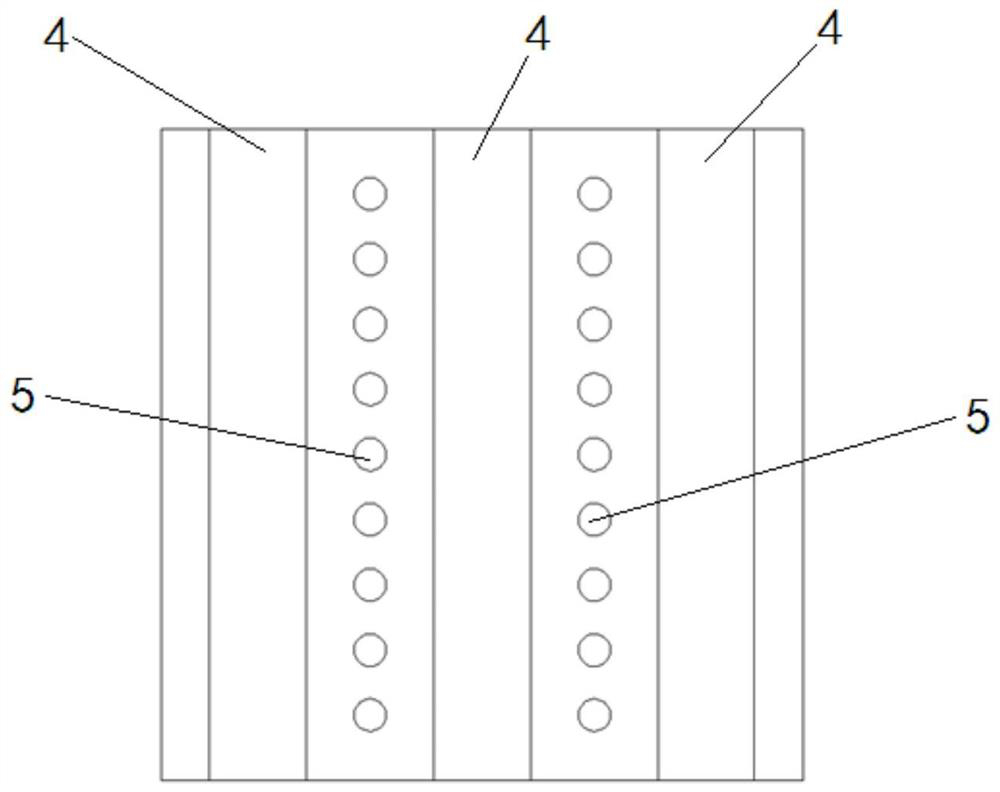

[0085] First prepare the energy storage sheet 3. The material for the energy storage sheet 3 is a binary mixture of sulfoaluminate cement and gypsum. The mixing ratio of sulfoaluminate cement and gypsum should be controlled between 8:2 and 7:3. Before mixing, the two materials should be fully mixed to ensure full contact during hydration. The water-cement ratio should be controlled between 7.4 and 7.7. In order to ensure a sufficient hydration reaction and obtain a sufficient amount of ettringite, water should be added before mixing. (demineralized and desalinated pure water) and then add the mixture of sulfoaluminate cement and gypsum, and fully stir to obtain cement slurry.

[0086] In order to prevent the energy s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com