Displacement amplification ultrasonic linear motor and working method thereof

A technology of displacement amplification and linear motors, which is applied to generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as low efficiency, large loss, and short life, and achieve Reduced manufacturing cost, low work loss, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

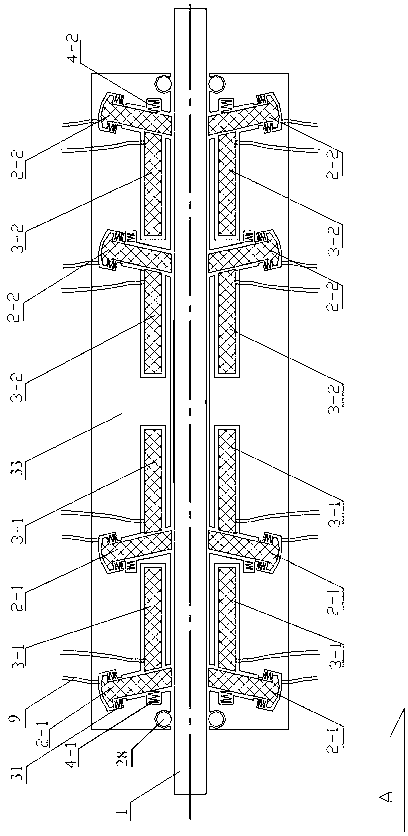

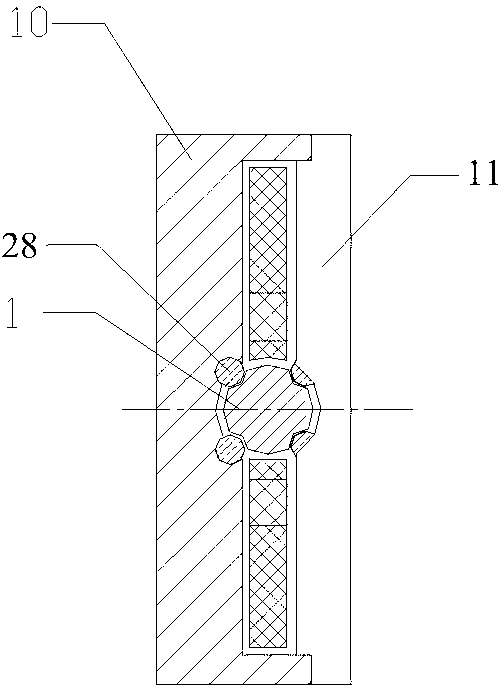

[0047] Such as figure 1 and 2 As shown, the present invention is mainly composed of a motor stator with a central hole and a motor mover 1 penetrating through the central hole. The motor stator is mainly composed of a stator housing and a radial concave The stator housing is mainly composed of the stator housing A11 and the stator housing B12 buckled together, and the radial groove and the axial groove are arranged radially and vertically along the central hole respectively. Axial setting; one end of the radial groove communicates with the central hole, and the left or right side of the radial groove is provided with a spring groove communicating with it; the axial groove is located on the right side of the radial groove Or the left side, and communicate with the radial groove; the radial piezoelectric strip is arranged in the radial groove, the axial piezoelectric strip is arranged in the axial groove, and the spring one is arranged in the spring groove.

[0048] In the pr...

Embodiment 2

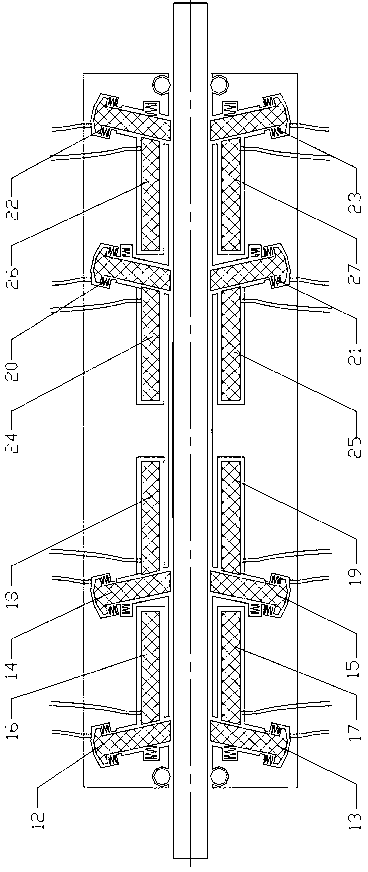

[0063] Due to the existing piezoelectric materials or components used to manufacture piezoelectric strips, the displacement (stretch) of each power-on and power-off cycle can only be a few thousandths of the device size at most, but can be a few percent The device is still under development, and the technology is very difficult; and the cost of the piezoelectric strip is high. If the displacement (stretching) of each power-on and power-off cycle is to be increased, the usage of the piezoelectric strip will inevitably increase, which will increase the manufacturing cost of the motor. In order to overcome the above shortcomings, increase the displacement stroke of each action cycle, thereby increasing the speed of the motor, making up for the speed of this type of motor and reducing the manufacturing cost, such as Figure 4 As shown, in the present invention, the end of the radial groove far away from the central hole is also connected with a radial force arm cavity and a radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com