Air detection heavy-duty floating support

A floating support and heavy-duty technology, which is applied in the field of components in the field of mechanical processing, can solve the problems of non-automatic cleaning and detection of sticky chips on the positioning surface, poor rigidity, low positioning accuracy and repeat positioning accuracy, and achieve good rigidity and independence. Strong, the effect of preventing work mistakes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

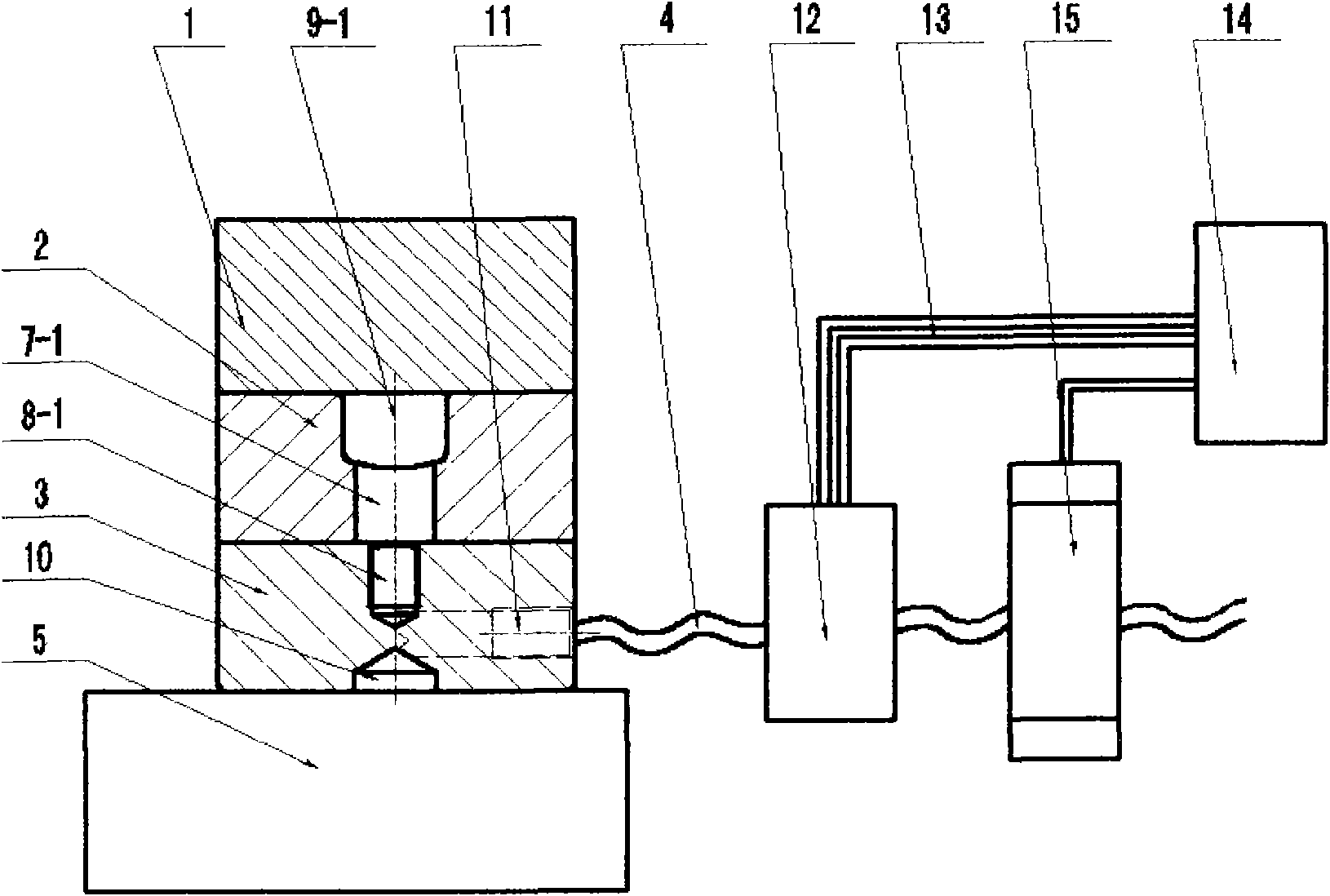

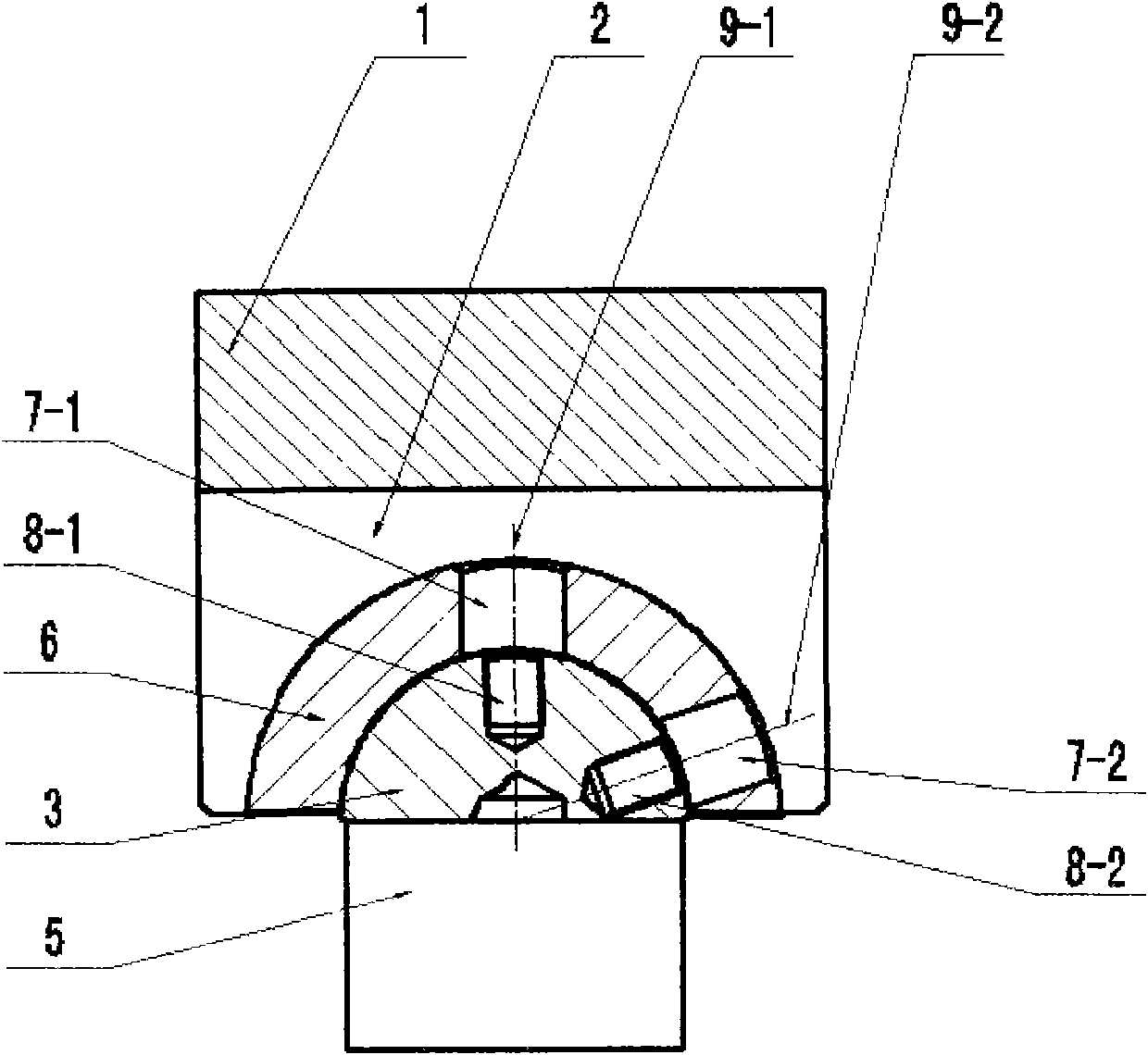

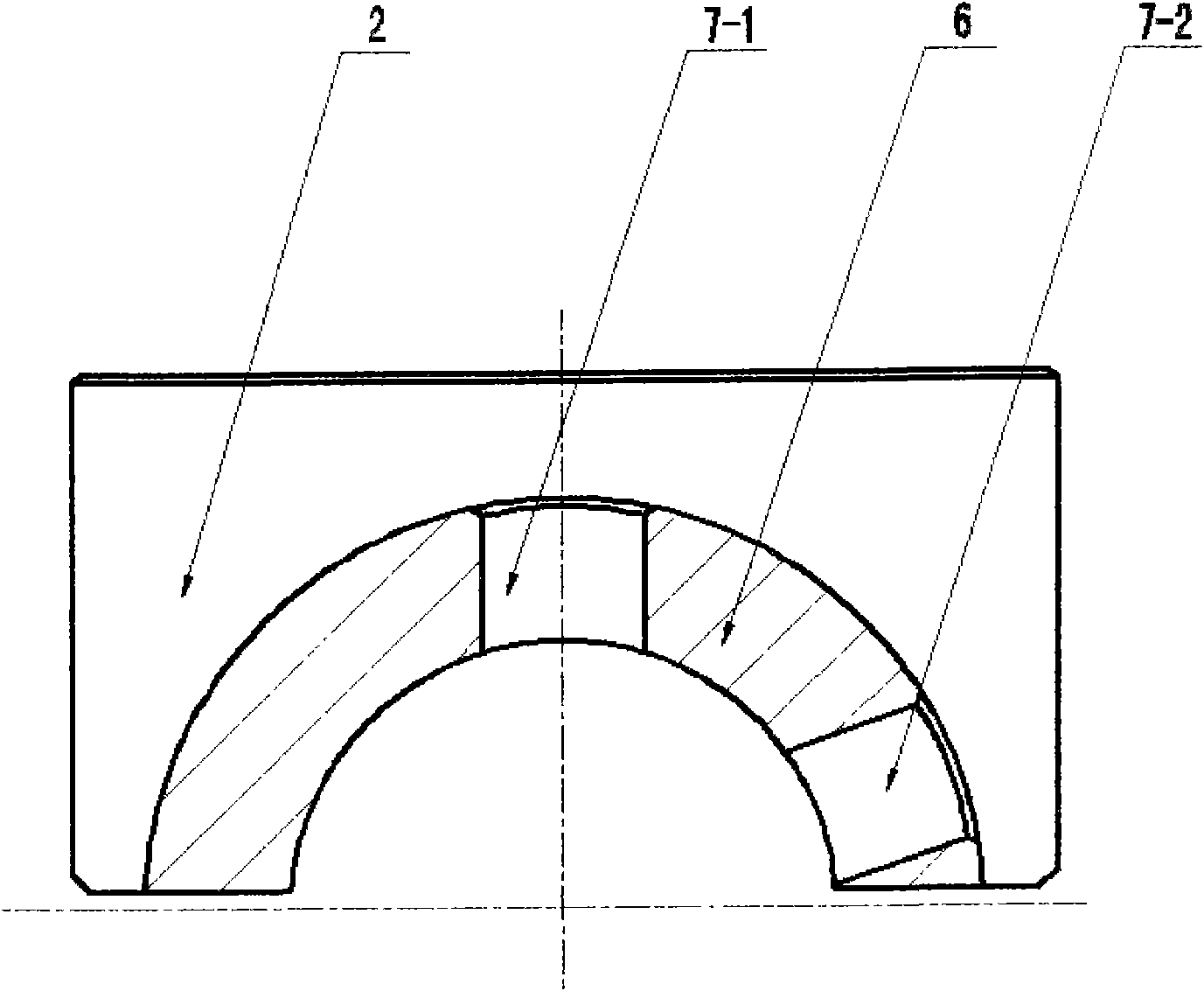

[0016] figure 1 , figure 2 Among them, the present invention includes a height adjustment block 1, a floating support seat 2, a floating positioning block 3, an air pipe 4, a support block 5, and the like. The height adjustment block 1 is fixedly connected to the upper end of the floating support seat 2, and there is a semicircular groove block 6 at the bottom of the floating support seat 2, and a waist hole 7-1 and a waist hole 7 are respectively opened in the middle and side of the semicircle groove block 6 -2. The upper end surface of the floating positioning block 3 is semi-cylindrical, and its shape and size match with the semicircular groove block 6 . A threaded blind hole 8-1 and a threaded blind hole 8-2 are respectively opened in the middle and side of the upper end surface of the floating positioning block 3, and the screw 9-1 and the screw 9-2 pass through the waist hole 7-1 and the waist hole 7. -2 Connect the threaded blind hole 8-1 and the threaded blind hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com