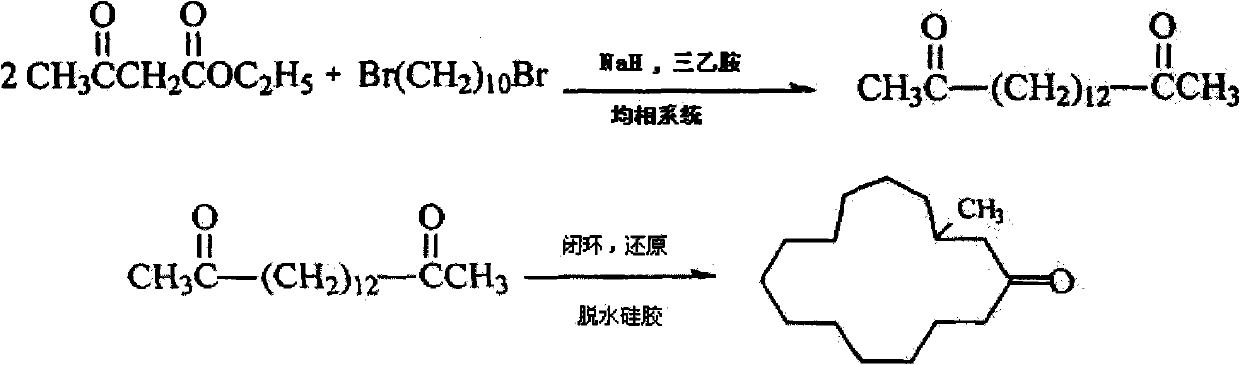

Process for preparing musk ketone

A preparation process, muscone technology, is applied to the chemical total synthesis of natural active ingredients. , The field of process route improvement for the synthesis of muskone can solve the problems of complex operation, inconvenient post-processing, long reaction cycle, etc., and achieve the effect of faster reaction speed and higher yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 100 mL of dry tetrahydrofuran, 20 g of ethyl acetoacetate, 2.21 g of Na, and 35 mL of triethylamine into a 250 mL flask, stir at room temperature for 20 min, and add 11 g (36.7 mmol) of a tetrahydrofuran solution of 1,10-dibromodecane dropwise under stirring . After the reaction was completed, a light yellow liquid was obtained by filtration, and the solvent was recovered under reduced pressure to obtain a yellow solid residue. After the flask was cooled to room temperature, the prepared aqueous alkali solution (10g NaOH, 70mL water, 30mL absolute ethanol) was added thereto, heated to reflux at 85°C for 2 hours, the brown liquid was collected by filtration while it was hot, and it was left to cool to obtain a solid. Filter, then dissolve the solid with about 200 mL of dichloromethane, and remove the insoluble matter by filtration to obtain a light yellow liquid. The organic phase was recovered under reduced pressure to obtain a gray solid, which was recrystallized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com