Paper feeding device of embroidery machine

A technology for a paper feeding device and an embroidery machine, which is applied to the mechanism of the embroidery machine, the embroidery machine, the feeding device, etc., can solve the problems of increasing the labor intensity of cleaners, not using the backing paper, wasting labor resources, etc. Simple, easy to manufacture, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be specifically described below with reference to the drawings.

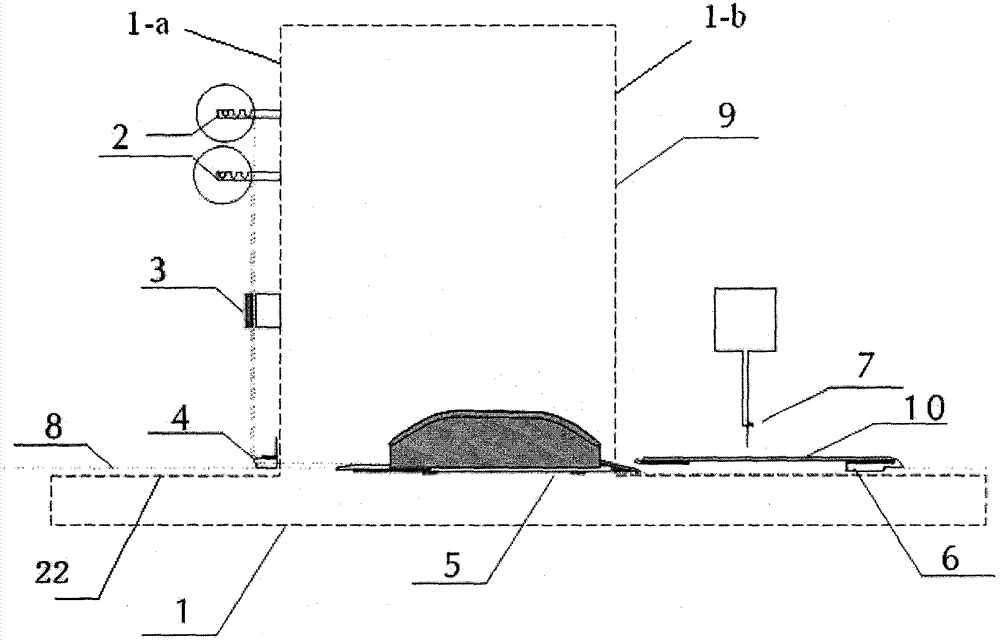

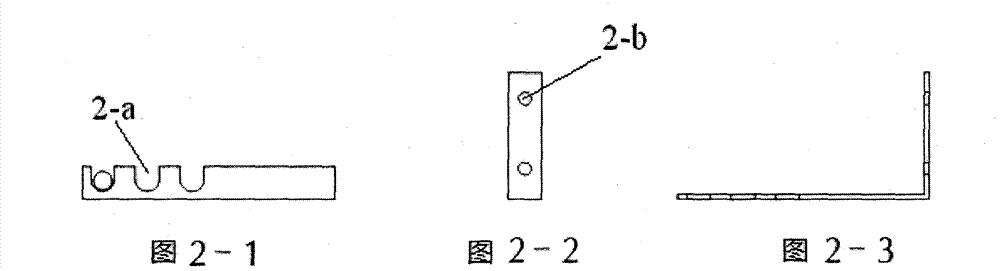

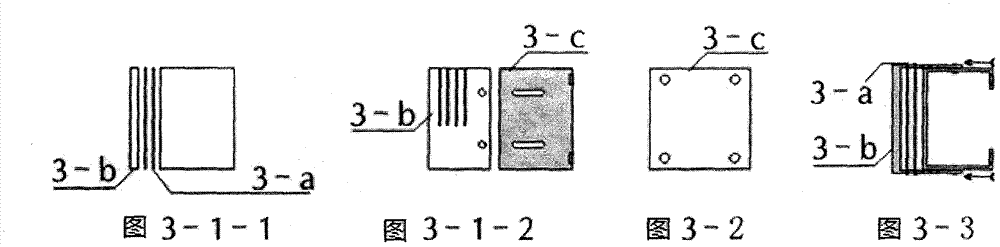

[0038] A paper feeding device for an embroidery machine described in this embodiment, such as figure 1 As shown, the above-mentioned embroidery machine mainly includes an embroidery machine platen (1), an embroidery machine beam (9), an embroidery machine stretch frame (22), an embroidery machine stretch lining (8), a multi-layer roll paper stand (2), a paper press Flat tension structure (3), multi-layer paper combined with turning structure (4), semi-automatic paper feeder (5) and a peripheral sticking frame (6) of convertible embroidery patterns.

[0039] The embroidery machine girder (9) is vertically on the embroidery machine platen (1), the embroidery machine girder (9) includes the embroidery machine girder rear side support beam (1-a) and the embroidery machine girder front side support beam (1-b), The embroidery underlayment is placed on the embroidery m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com