Membrane switch and manufacturing method thereof

A membrane switch and manufacturing method technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of complex manufacturing process, high production process requirements, and the failure of the upper film and upper conductive layer to be reset in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will now be further described with reference to the description of the drawings and the specific embodiments.

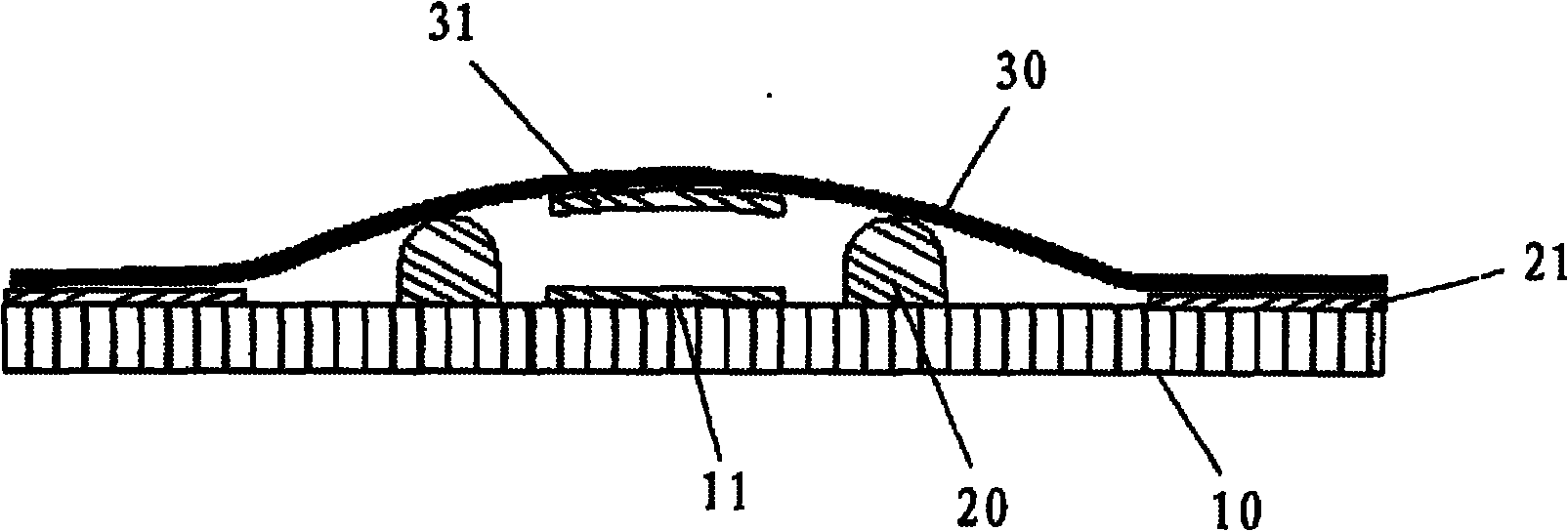

[0027] see figure 1 As shown, the membrane switch provided by the present invention includes an upper layer film 30 and an upper conductive layer 31 printed thereon, a lower base layer 10 and a lower conductive layer 11 printed thereon, and a UV gasket layer placed between the upper and lower conductive layers. 20 and the glue layer 21, wherein the lower base layer 10 is a PCB board, and the gasket ring of the UV gasket layer 20 is distributed on the periphery of the key position of the upper conductive layer 30 and the lower conductive layer 10, and the upper conductive layer 30 and the lower base layer 10 are bonded together by a glue layer 21 on the periphery of the UV gasket layer 20 and the periphery of the membrane switch.

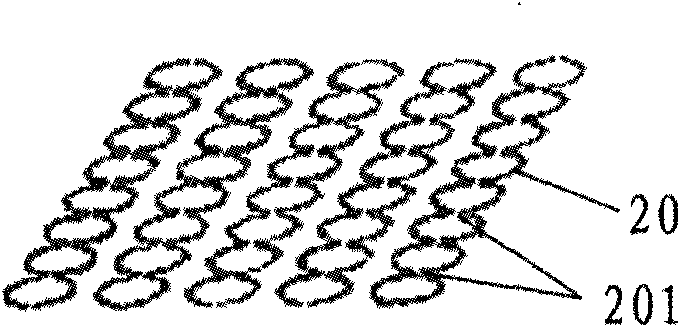

[0028] Further, see figure 2 As shown, the thickness of the gasket layer of the UV gasket layer 20 is grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com