Acid injection and flow guiding device of 12V storage battery

A diversion device and storage battery technology, applied in the direction of battery components, circuits, electrical components, etc., can solve the problems of inconsistent injection quantity, affecting the sealing effect of the interface, wear and deformation, etc., and achieve a stable and reliable sealing effect. Quantitative acid injection is reliable and accurate, and the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

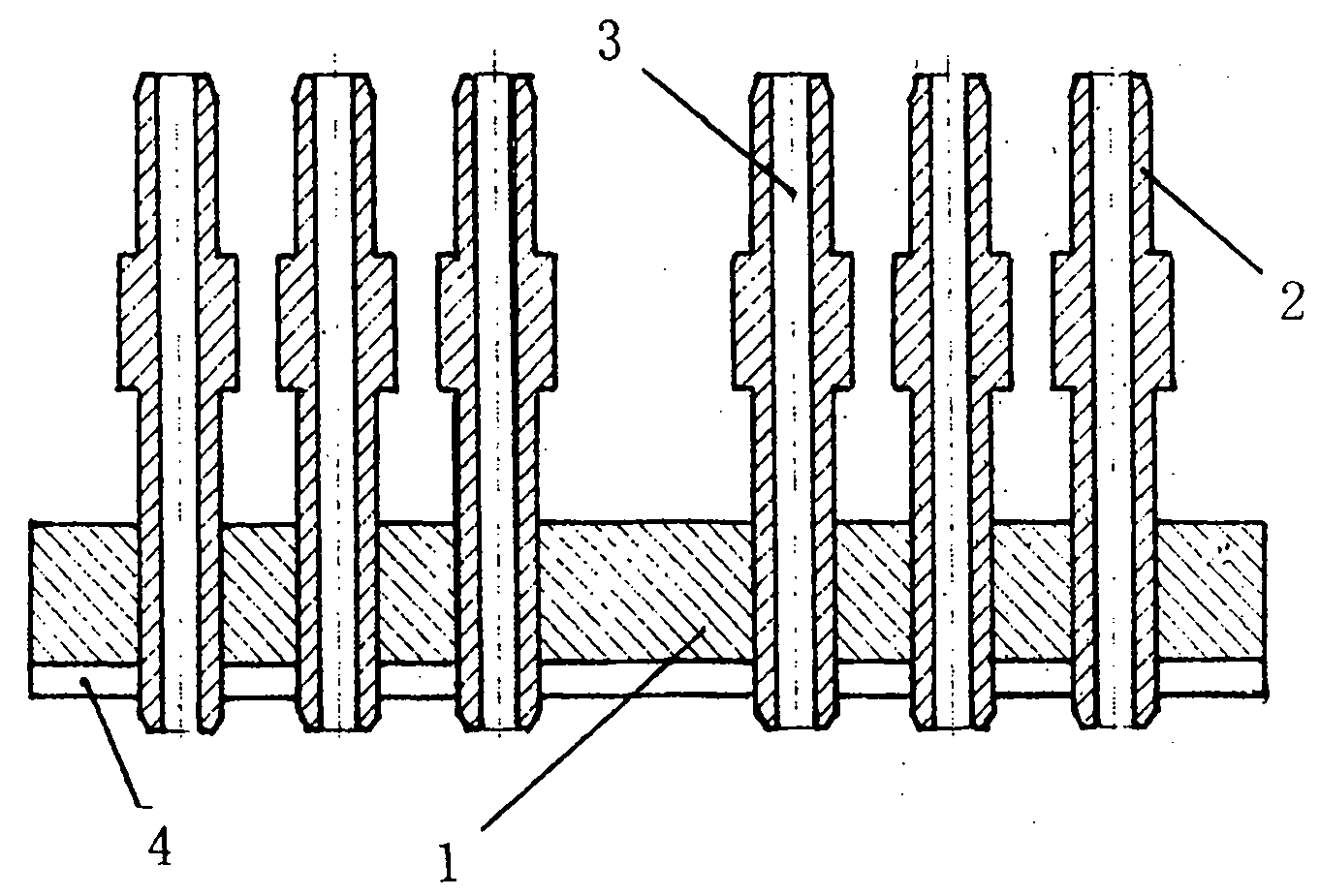

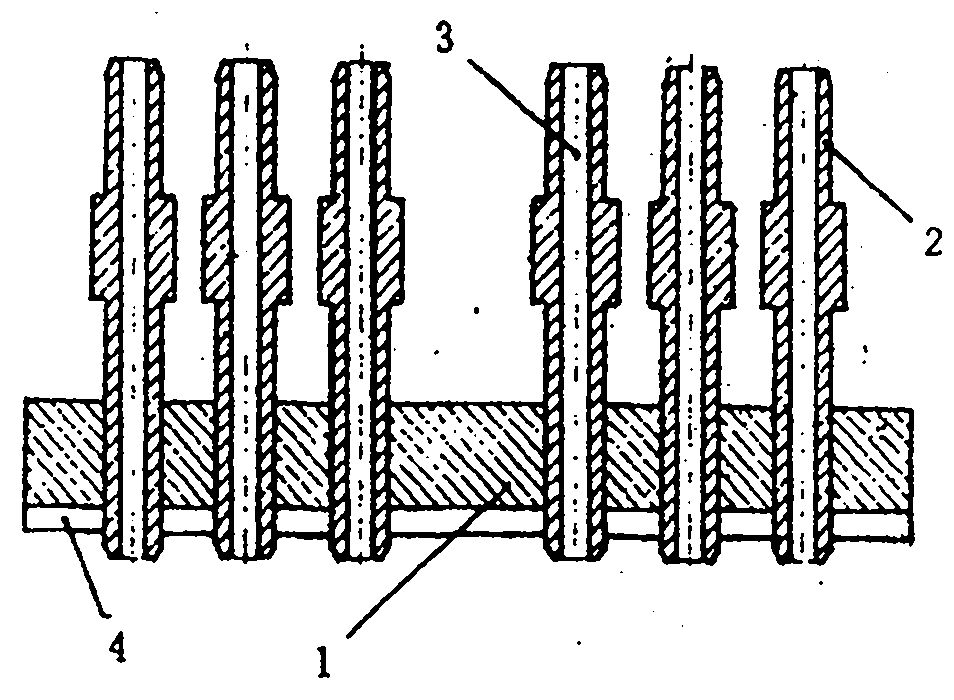

[0012] As shown in the embodiment of the accompanying drawings: the 6 diversion tubes 2 arranged equidistantly from the 6 acid injection holes on the top of the 12V battery are fixed as a whole by the fixed pressure plate 1 . A sealing gasket 4 is arranged under the fixed platen 1. Six diversion tubes 2 vertically penetrate the fixed platen 1 and are fixed as a whole. The fixed platen 1 is located under the guide tube 2, and the guide tube is exposed under the fixed platen. 2, the exposed 6 tube heads are flush. The six diversion pipes 2 are all provided with diversion holes 3 for vertical conduction.

[0013] During specific implementation, the fixed platen 1, the guide tube 2 and the gasket 3 should all be produced by acid-resistant materials, and the fixed platen 1 should have a certain thickness to ensure overall stability and durability. Six guide tubes 2 The arrangement distance and orientation of the battery should be consistent with the arrangement distance of the aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com