Composite material and method for producing the same and composite material for plant cultivation and method for using the same

A composite material and plant cultivation technology, applied in the field of composite materials and its manufacturing, can solve the problems of lack of fertilizer retention in the medium, achieve excellent water retention and reduce environmental load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

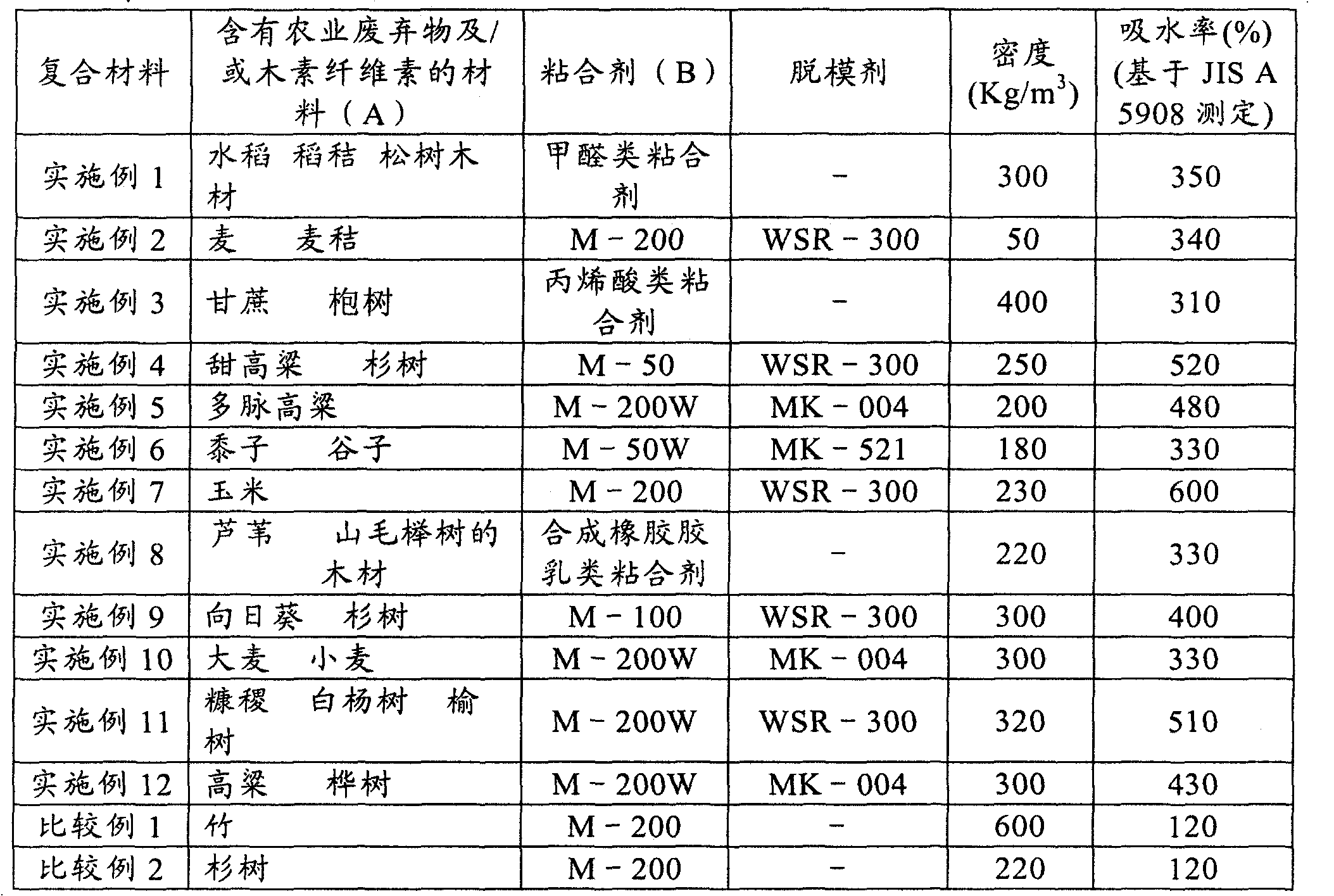

[0148] Example

[0149] Hereinafter, preparation examples, examples, and comparative examples of the present invention will be given and described, but the present invention is not limited to the examples and the like.

Example

[0150] [Preparation Examples of Adhesives (A1 and A2)]

[0151] (Preparation of acrylic adhesive)

[0152] The emulsified monomer (a1) was prepared as follows: a mixture of 100 parts by weight of the monomer mixture (Aa1) and 0.5 parts by weight of a chain transfer agent (t-dodecanethiol) mixed in the ratio shown in Table 1 was dropped while stirring. into a mixed solution of 50 parts by weight of distilled water and 0.5 part by weight of sodium dodecylbenzenesulfonate. In addition, the emulsified monomer (a2) was prepared in the same manner as the emulsified monomer (a1) using the monomer mixture (Aa2) mixed in the ratio shown in Table 1.

[0153] Next, 95 parts by weight of distilled water and 0.1 part by weight of sodium dodecylbenzenesulfonate were added to a 1-liter flask, and the temperature was raised to 70° C. while stirring under nitrogen sealing, and then 1 part by weight of the above-mentioned emulsifying monomer (a1) was added. Or (a2), and 0.5 weight part of pot...

Example

[0156] [Preparation Example of Adhesive (B1)]

[0157] (Preparation of synthetic rubber latex adhesive)

[0158] The emulsified monomer (b1) was prepared as follows: a mixture of 1000 parts by weight of the monomer mixture (Bb1) and 5 parts by weight of the chain transfer agent (t-dodecanethiol) mixed in the ratio shown in Table 1 was dropped while stirring. into a mixed solution of 500 parts by weight of distilled water and 2 parts by weight of sodium dodecylbenzenesulfonate.

[0159] On the other hand, 500 parts by weight of distilled water, 1 part by weight of sodium dodecylbenzenesulfonate, and 5 parts by weight of potassium persulfate were placed in a 3-liter autoclave with a stirrer and sealed. After that, pressurize with nitrogen until the pressure in the autoclave becomes 5 kg / cm 2 , after standing for 5 minutes to check whether there is leakage, reduce the pressure to 500mmHg. The above-mentioned operation (pressurization-standstill-decompression) was repeated twic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com