Clearing device of through holes of purifier carrier

A technology of purifier and carrier, which is applied in the field of through-hole clearing device of purifier carrier, which can solve the problems that the through-hole cannot be blown through, reduce the emission of particulate matter, etc., and achieve the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

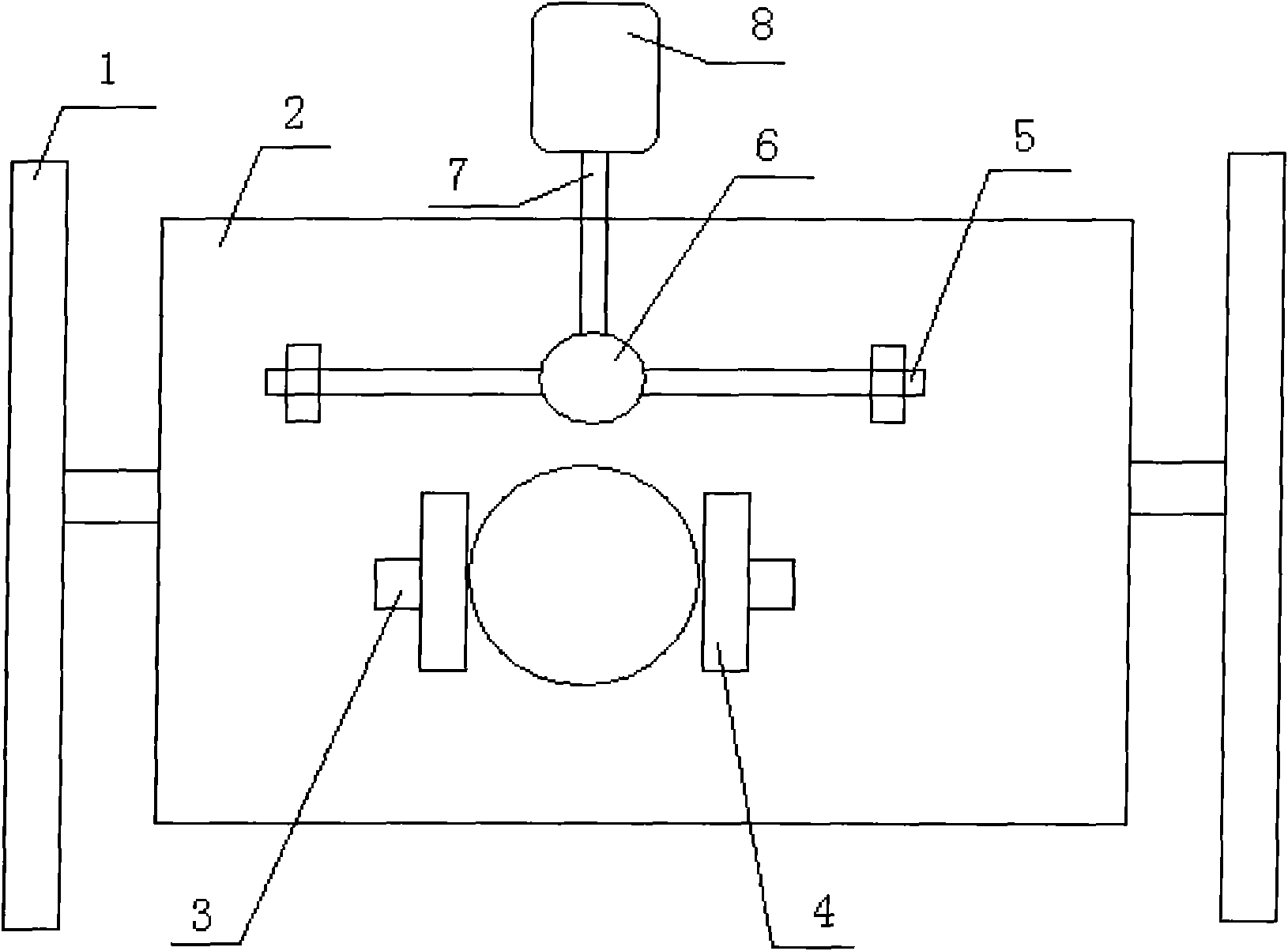

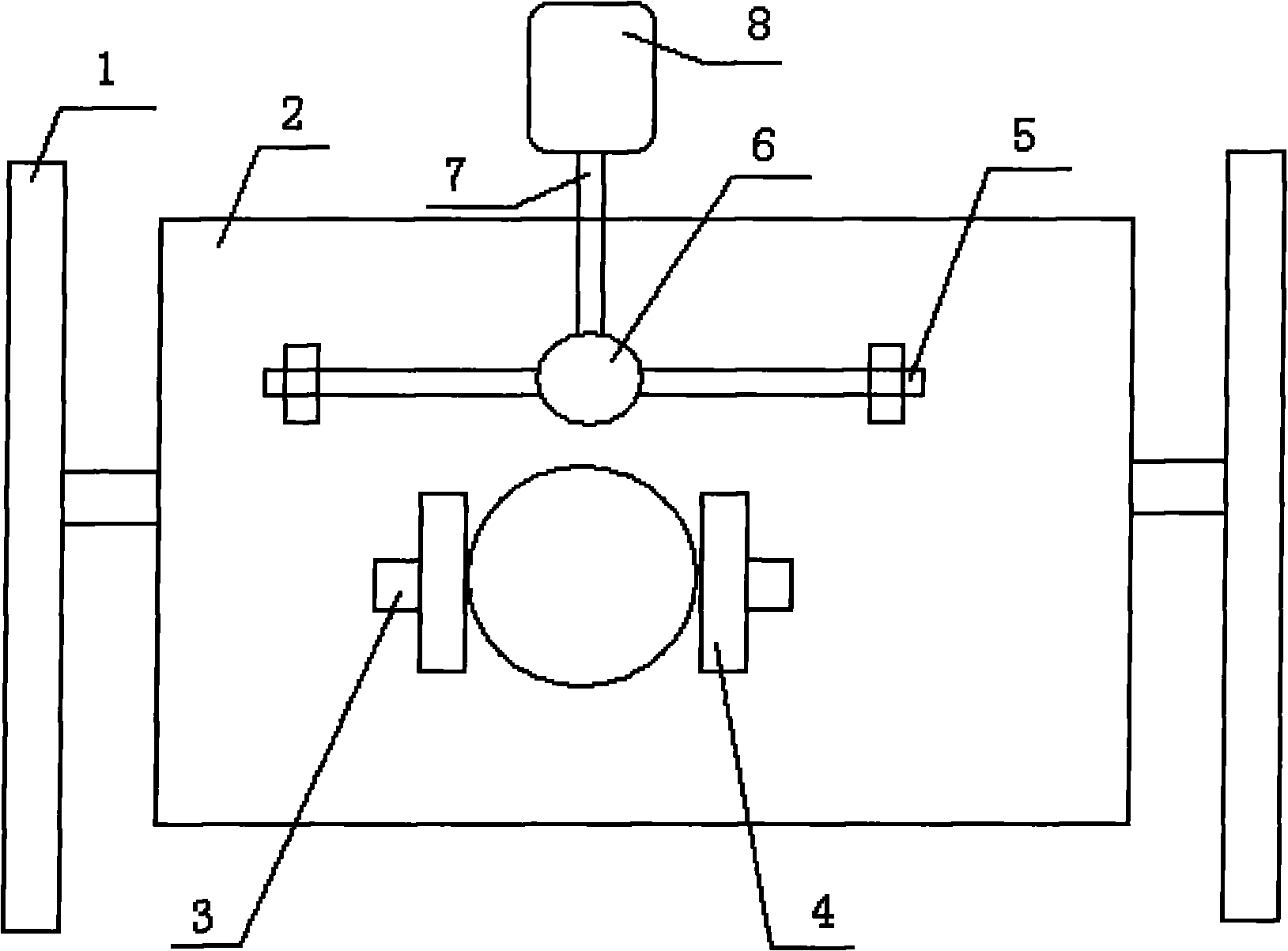

[0012] A purifier carrier through-hole clearing device, including a frame 1: a box body 2 is installed on the upper end of the frame 1, a pair of support rods 3 are installed in the box body 2, a splint 4 is installed on the upper end of the support rod 3, and the inside of the box body 2 The lateral bar 5 is also installed on the side of the support bar 3, and the air knife 6 is slidably installed on the transverse bar 5. The air knife 6 has a cylindrical metal cutter head with a slit, and the cutter head is connected by a pipe 7. to a high pressure air source 8 . The gas source communicates with the slit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com