A wire head positioning and welding structure of a winding machine

A welding structure and winding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of troublesome wire grabbing and complicated positioning, and achieve the effect of high work efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

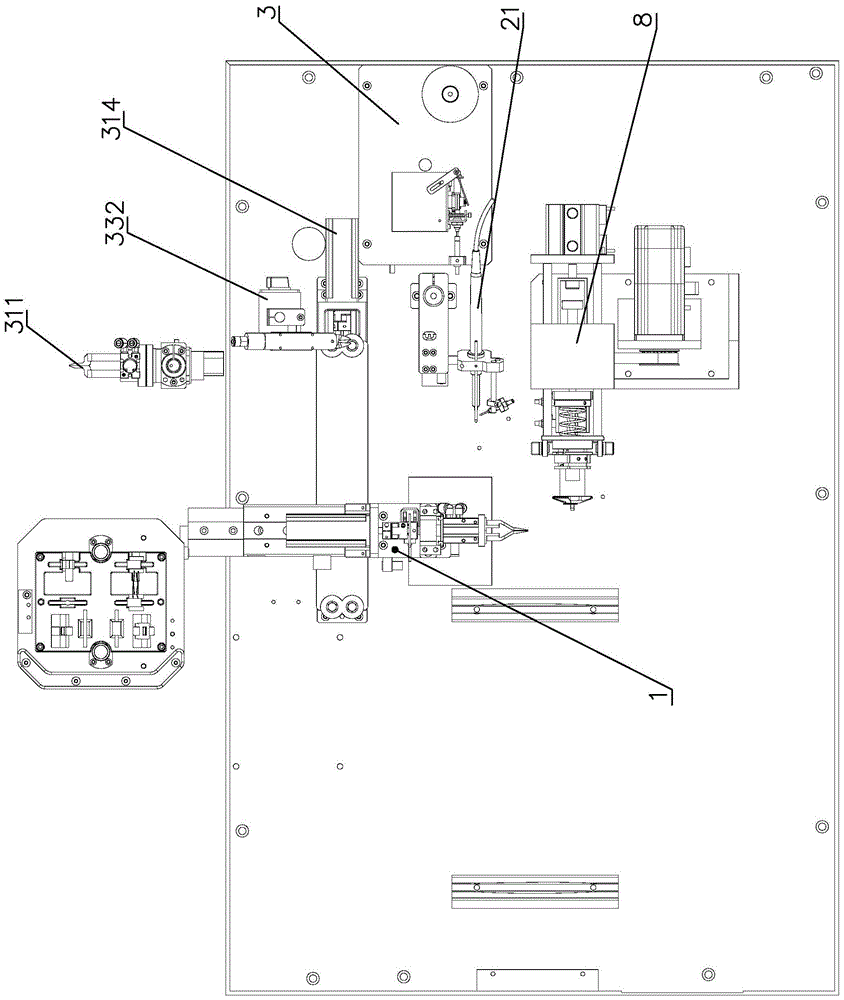

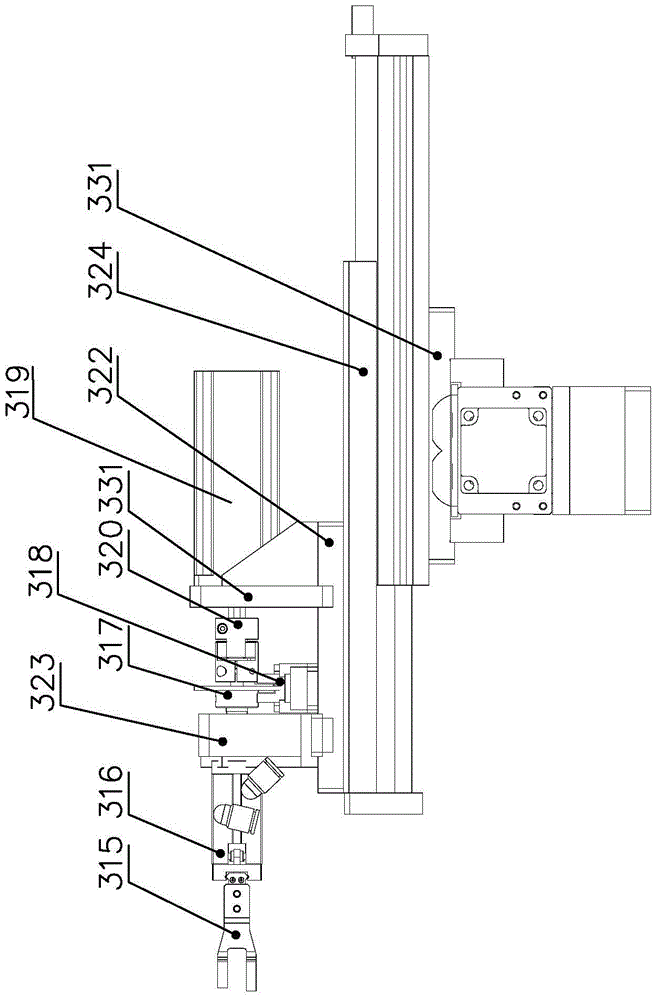

[0021] see Figure 1 to Figure 4 , in order to achieve the above object, the present invention provides a wire end positioning and welding structure, the wire end positioning structure 1 and the welding structure 2 are fixed on the winding machine, wherein the winding machine includes grabbing raw materials from the assembly line Mechanical arm 31, and thread cutting structure 33.

[0022] The mechanical arm 31 of the winding machine is mainly used for grabbing raw materials from the assembly line and intermediate products processed on the winding machine. The mechanical arm 31 can also cooperate with other mechanisms to fix the PCB board with the winding structure 3 .

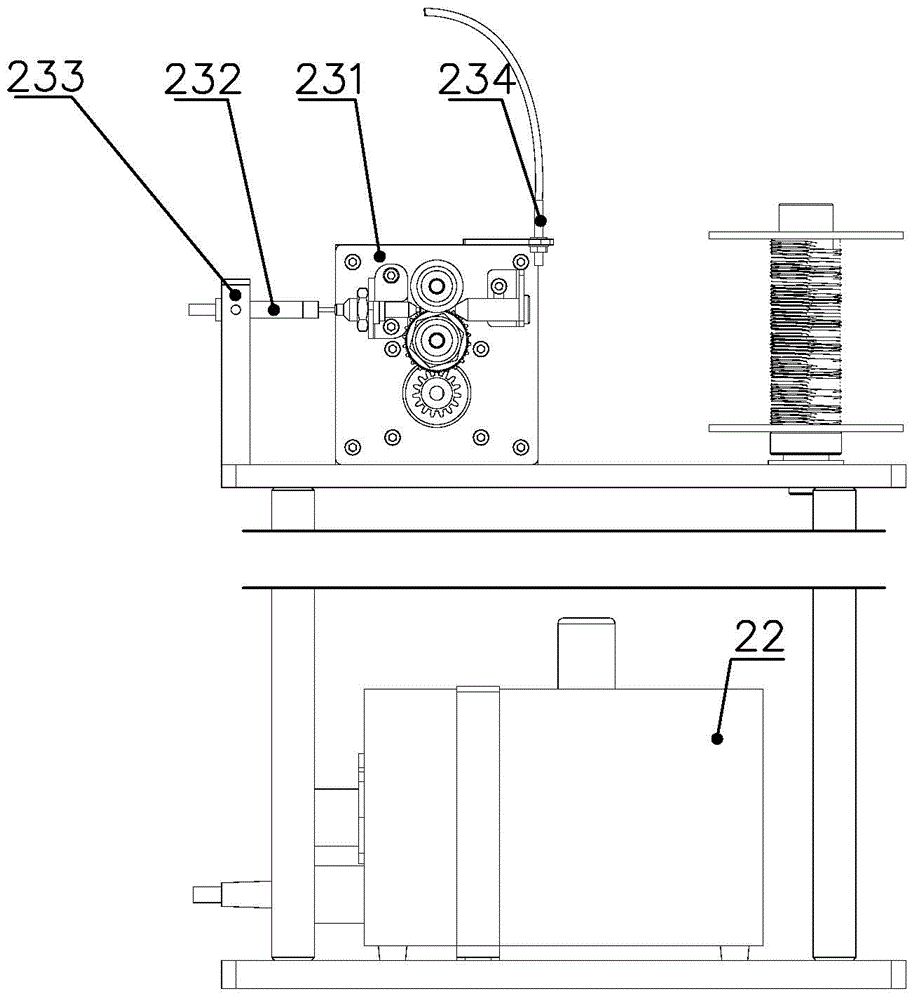

[0023] The wire cutting structure 32 includes a support structure 331 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com