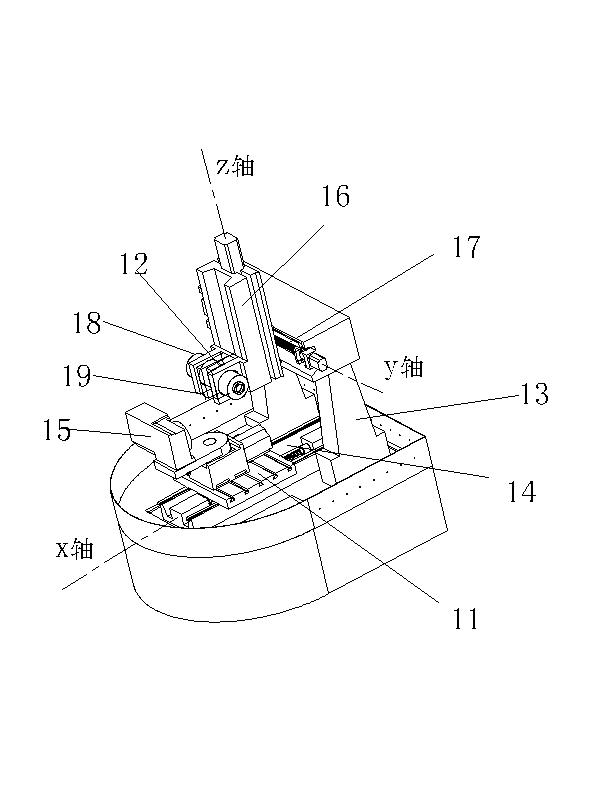

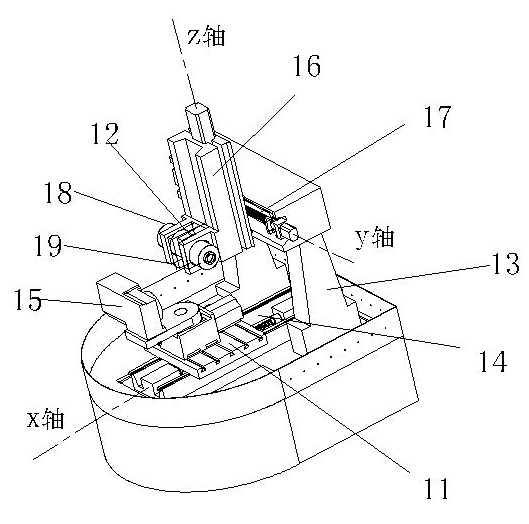

Five-axis linkage tool grinder with detection device

A tool grinder and detection device technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve problems affecting work efficiency, difficult positioning of products, etc., achieve accurate processing positioning, reduce clamping and adjustment times, and high precision The effect of parts processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0009] Embodiment: a five-axis linkage tool grinder with a detection device, the tool grinder includes a worktable 11, a main shaft 12 and a column 13, and an X-axis slide rail 14 and an X-direction drive device are arranged under the workbench 11. The workbench 11X is axially slid and fixed on the X-axis slide rail 14, and a positioning block 15 that can rotate around the X and Z axes (that is, A and C steering) is fixed on the workbench 11. The spindle 12 is fixed on the workbench 11 The sliding table 16 above, the sliding table 16 is positioned on the side of the column 13 close to the workbench 11 through the cross slide rail 17 along the Y and Z axis directions, and the slide table can move along the cross slide rail 17 toward Y, Z Sliding in the axial direction, the column 13 is provided with a Y-axis driving device, the slide table 16 is provided with a Z-axis driving device, and the main shaft is also provided with a detection device 19 .

[0010] Both ends of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com