Sliding bearing material of elastoplastic polymer alloy

A sliding bearing and polymer technology, which is applied in the field of elastic-plastic polymer alloy sliding bearing materials, can solve the problems of poor self-lubricating effect, difficult to achieve dry start, and lubrication failure of the lubrication system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

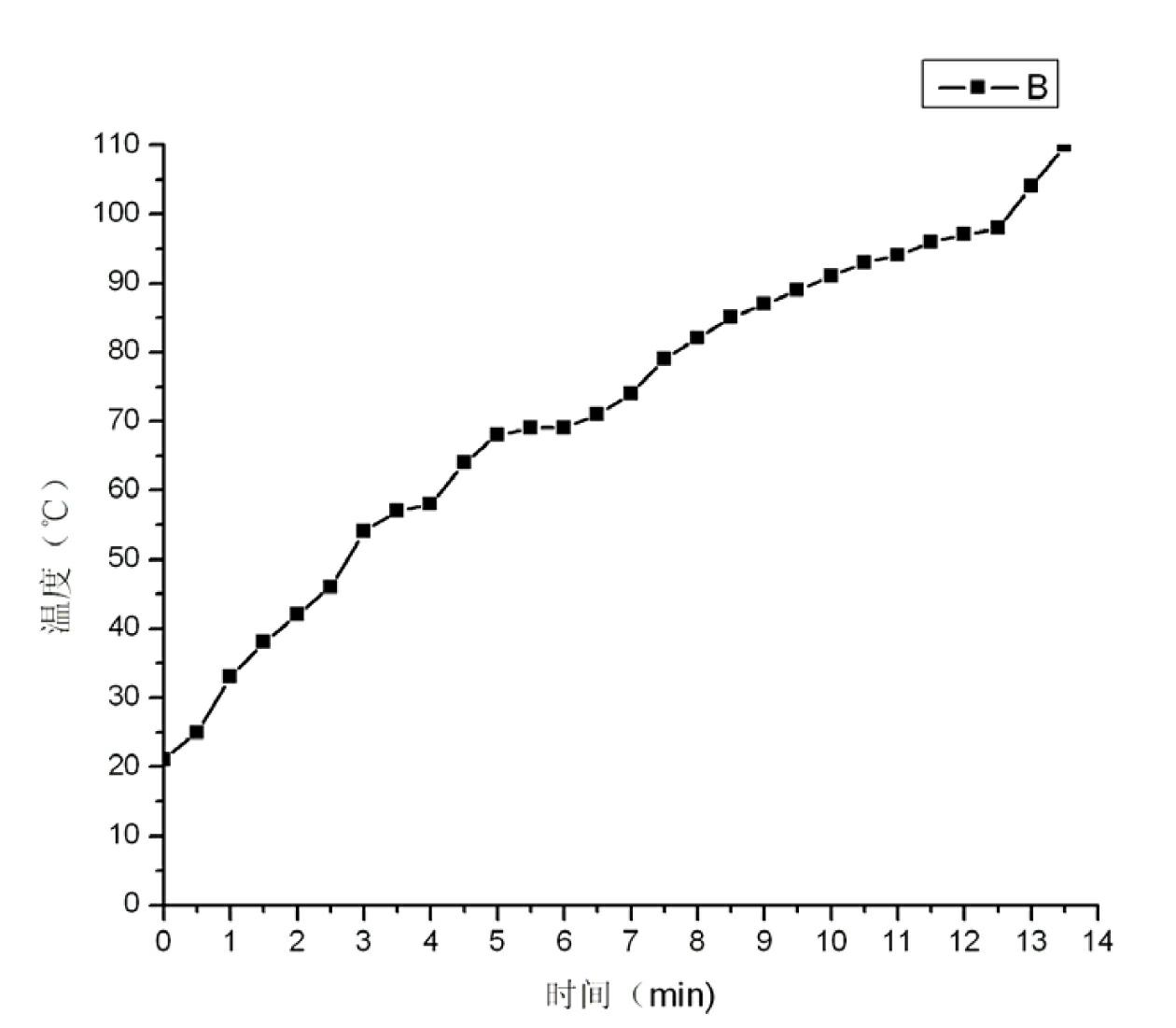

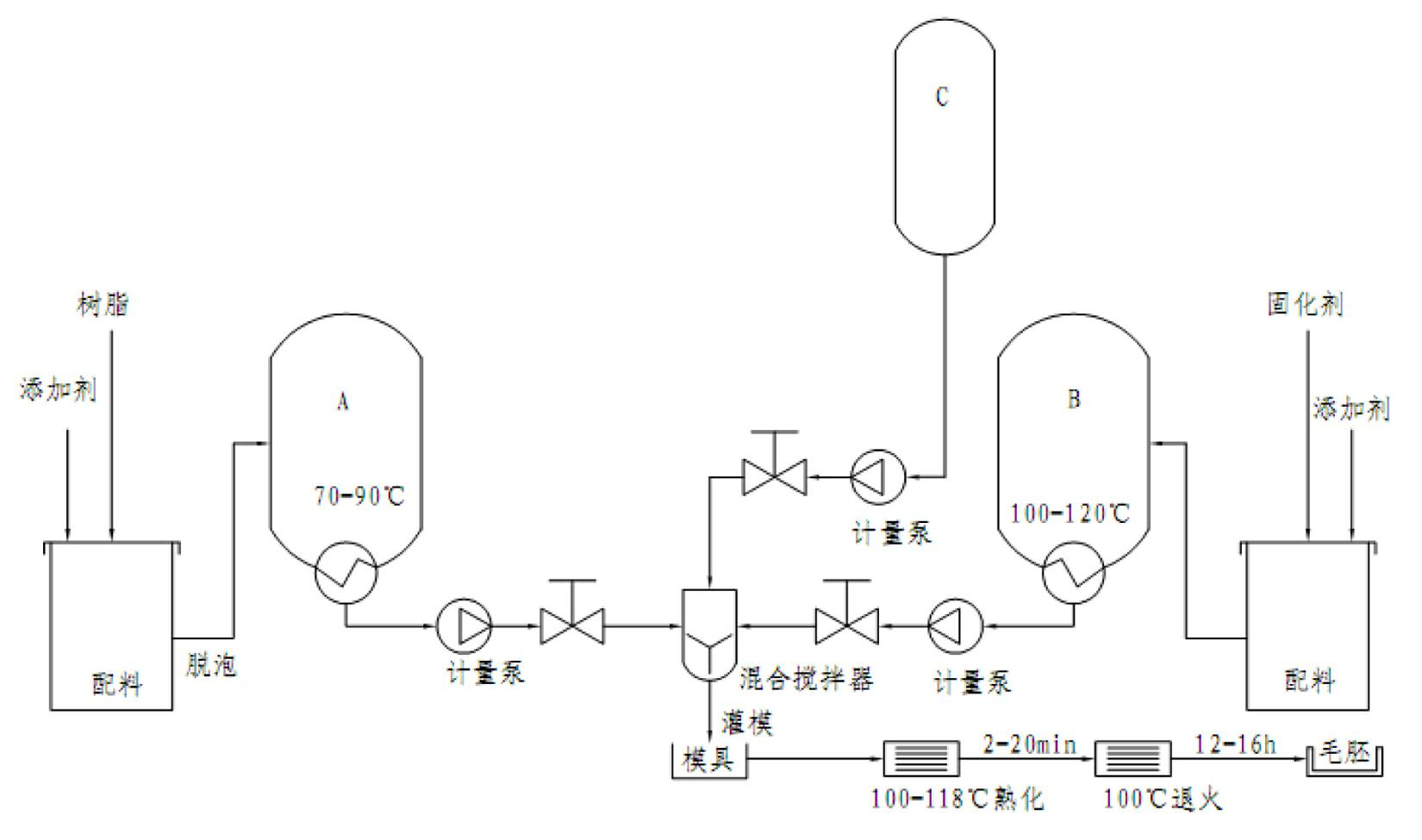

Image

Examples

Embodiment 1

[0033] Table 1 is the raw material composition of elastic-plastic polymer alloy sliding bearing material of the present invention:

[0034] Table 1: Raw material composition of elastoplastic polymer alloy sliding bearing materials

[0035] raw material

Embodiment 2

[0037] Table 2 is the raw material composition of elastic-plastic polymer alloy sliding bearing material of the present invention:

[0038] Table 2: Raw material composition of elastoplastic polymer alloy sliding bearing materials

[0039] raw material

[0040] Perfluoropolyether Grease (Model: Fluoroguard PCA)

Embodiment 3

[0042] Table 3 is the raw material composition of elastic-plastic polymer alloy sliding bearing material of the present invention:

[0043] Table 3: Raw material composition of elastoplastic polymer alloy sliding bearing materials

[0044] raw material

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap