Wire-line core drilling hydraulic impactor

A hydraulic impactor and rope coring technology, which is used in the extraction of undisturbed core devices, earthwork drilling and other directions, can solve the problems of small contact area of the seat ring, total growth, short life and other problems, and achieve structural strength and shock and vibration resistance performance. Enhanced, improved transfer efficiency, shortened drill assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

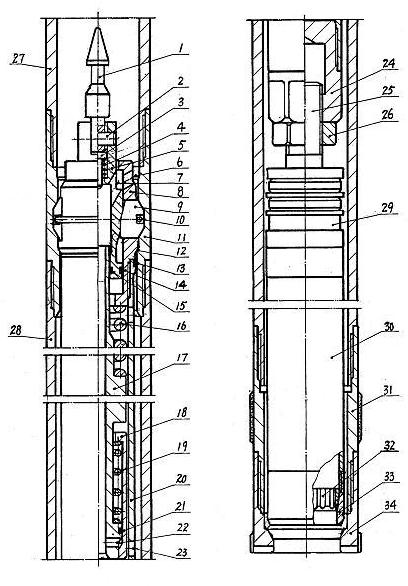

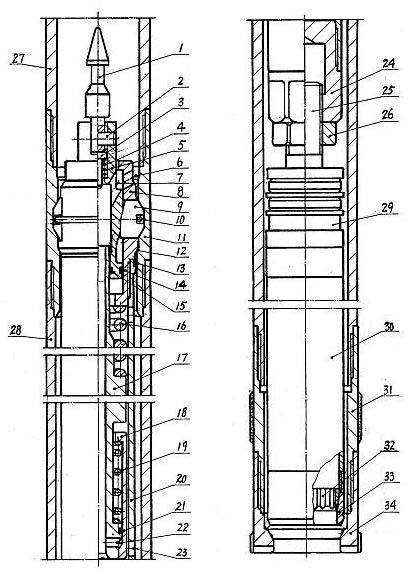

[0018] Such as figure 1 The rope coring hydraulic impactor shown has a throwing and fishing mechanism consisting of fishing spear head 1, threading pin 2, positioning pin 3, and positioning pin spring 4; wedging piston 5, positioning suspension seat 8, and positioning power transmission slider 9. Slider retraction spring 10, positioning suspension power transmission collar 11, sealing rings 13, 14, 15 form a hydraulic positioning suspension power transmission mechanism; hammer spring 16, hammer rod 17, sleeve valve 18, valve spring 19, shell 20 , sealing ring 21, anvil 24 constitute hydraulic impact mechanism.

[0019] The anvil 24 bottoms have screw holes to be connected with the connecting screw rod 25 on the single-action alarm mechanism 29 on the rope coring inner tube 30 top, after adjusting the gap between the spring seat 33 and the drill bit 34, lock it with the lock nut 26, and the outer tube 28 and the drill bit 34 are locked. A reamer 31 is installed between the dr...

Embodiment 2

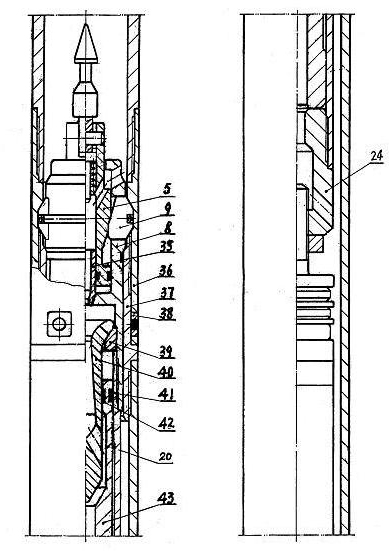

[0021] Such as figure 2 The shown rope coring hydraulic impactor is embodiment 2, which is different from embodiment 1 in that the hydraulic impact mechanism is composed of nozzle 35, valve travel seat 39, core valve 40, sealing rings 41, 42, housing 20, hammer body 43 and anvil 24, the nozzle 35 is installed in the wedging piston 5 for dynamic sealing fit, the valve travel seat 39 is fixed between the positioning suspension seat 8 and the shell 20, and the part below the valve crown of the core valve 40 passes through the valve travel seat 39 Inserted into the valve chamber on the upper part of the hammer body 43, the sealing rings 41 and 42 on the upper part of the hammer body 43 respectively cooperate with the positioning suspension seat 8 and the core valve 40 in dynamic sealing, and the two ends of the shell 20 are threadedly connected with the positioning suspension seat 8 and the anvil 24 respectively . When the drilling fluid passes through the nozzle 35, the hydraul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap