Hydraulic cylinder and cushioning device of hydraulic cylinder

A technology of buffering device and hydraulic cylinder, which is applied in the field of buffering of hydraulic cylinders and buffering devices of hydraulic cylinders, can solve the problems that the reliability of the buffering device cannot meet the actual needs, reduce the buffering effect of the buffering device, and damage the buffering device, so as to reduce the processing cost. Difficulty and processing cost, ensuring cushioning effect, and ensuring sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

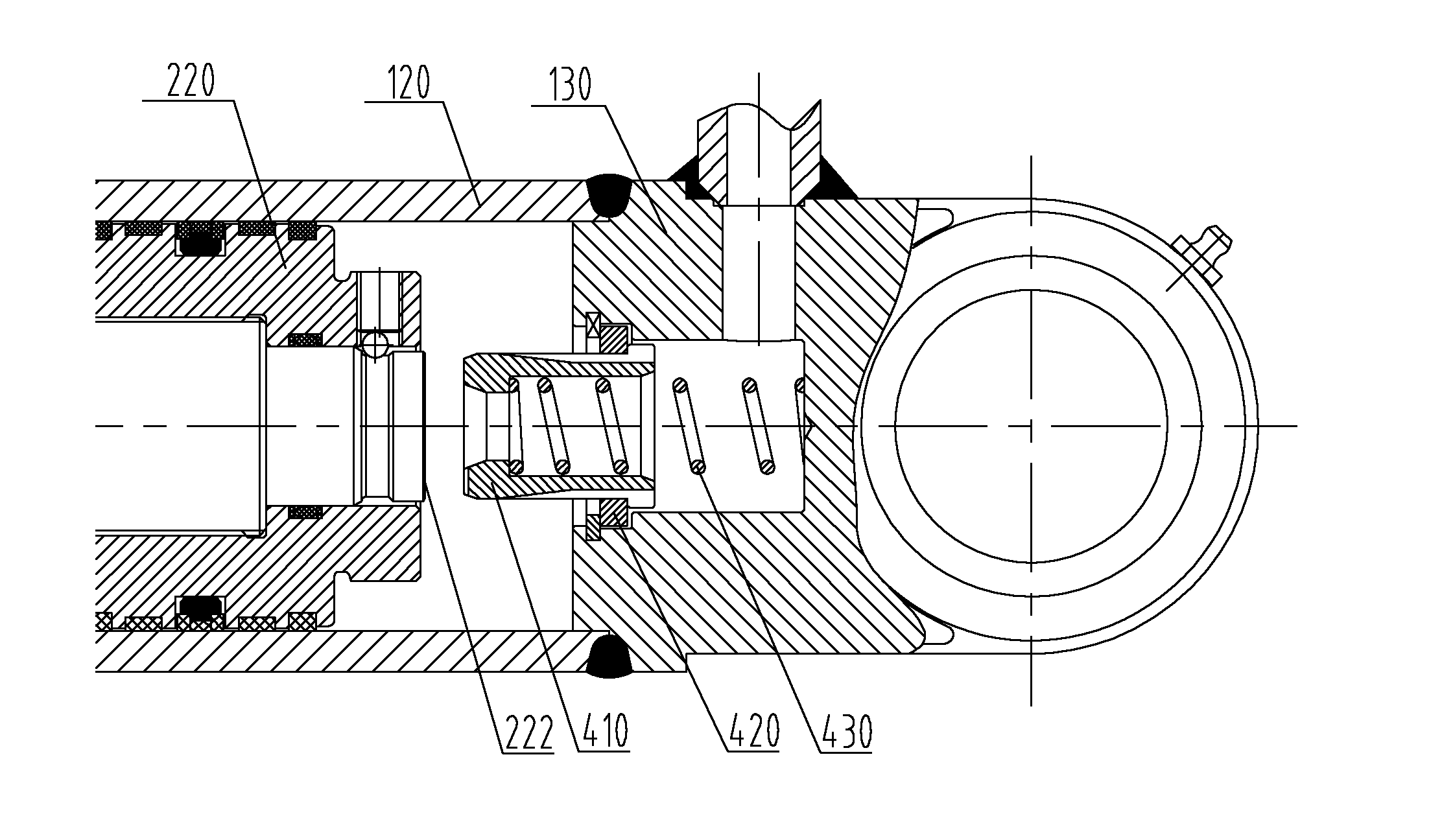

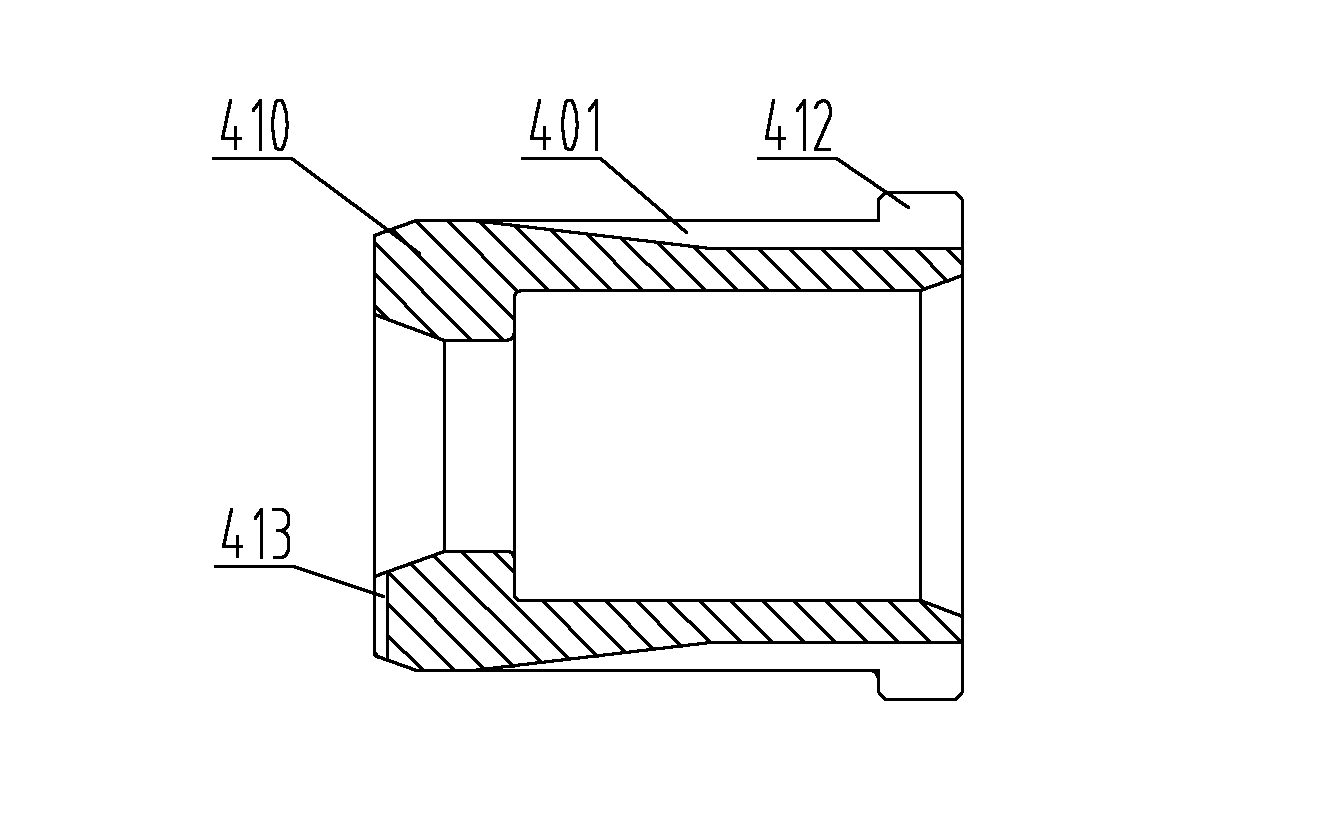

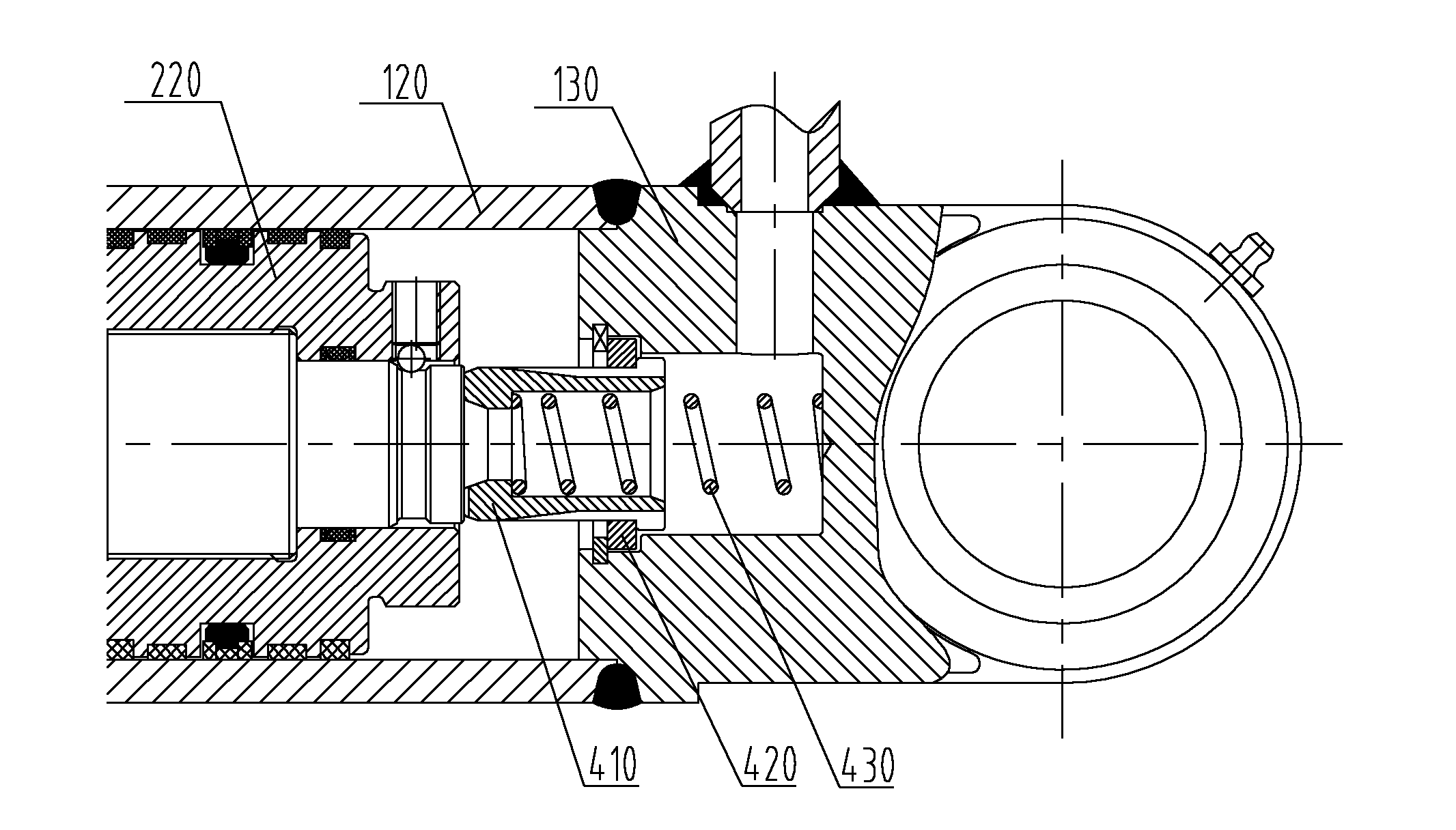

[0034] As described in the background art section, based on the problems existing in the prior art, the applicant analyzed the causes of the problems. The reason for the strain of the buffer sleeve and the guide sleeve is that the matching accuracy and level of cooperation between the outer wall surface of the buffer sleeve and the inner wall surface of the guide sleeve are low; In addition to the processing level and processing equipment, the factor for improving the coordination level is that the buffer sleeve moves with the piston during the buffering process. While moving, the buffer sleeve will produce deviations in the radial direction of the hydraulic cylinder. Furthermore, the matching error between the outer wall surface of the buffer sleeve and the inner wall surface of the guide sleeve increases. For this reason, the applicant proposed a technical scheme of keeping the buffer sleeve separated from the piston, and keeping the buffer sleeve and the outer buffer compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com