Equipment monitoring and diagnosing method

A technology of equipment and eigenvalues, which is applied in the field of monitoring and diagnosis at a fixed speed of the equipment, can solve the problems of affecting practicability and replication, over-learning sample explosion, and reducing application effectiveness, so as to achieve the effect of reducing scale and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

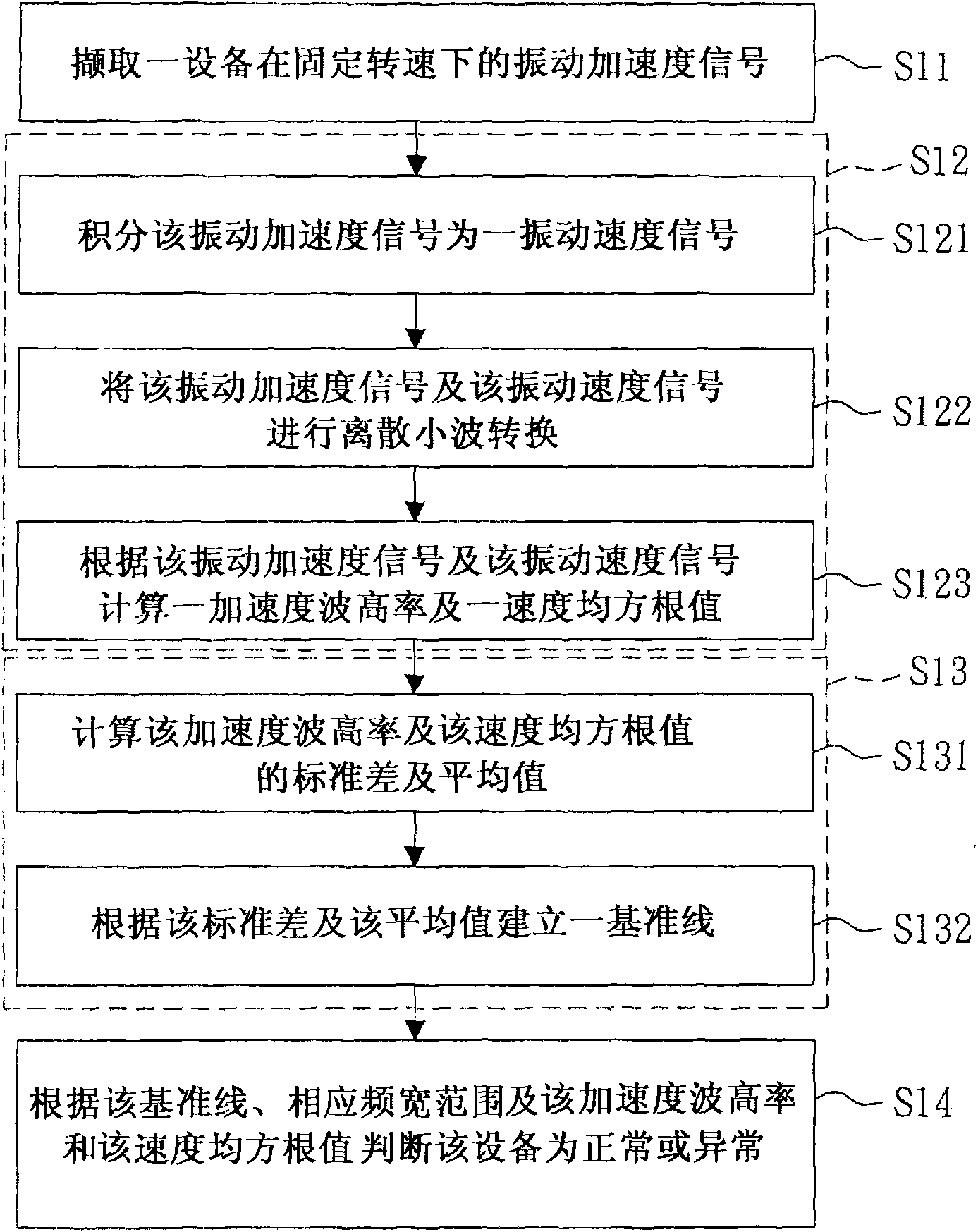

[0028] refer to figure 1 , which shows the flowchart of the device monitoring method of the present invention. The equipment monitoring and diagnosis method of the present invention is used for abnormal detection of an equipment, and the equipment can operate at a fixed speed. Firstly, referring to step S11, a vibration signal of the device at the fixed rotational speed is captured, wherein the frequency of the vibration signal has multiple frequency ranges.

[0029] In this embodiment, the method of the present invention continuously acquires a vibration acceleration signal of the device at the fixed rotational speed. Wherein, in step S11, a vibration sensor can be used to capture the vibration acceleration signal under the setting of fixed high-pass filter and low-pass filter cut-off frequency. Preferably, the cut-off frequency of the high-pass filter is set at 0.5 Hz, the cut-off frequency of the low-pass filter is set at 3000 Hz, and the vibration acceleration signal is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com