Evaluating method for annealing quality of cold rolled plain carbon steel

An evaluation method, the technology of ordinary carbon steel, is applied in the direction of measuring device, preparation of test samples, material analysis through optical means, etc. Rolling common carbon steel annealing quality and other issues, to achieve the effect of intuitive evaluation method, satisfying smooth production, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

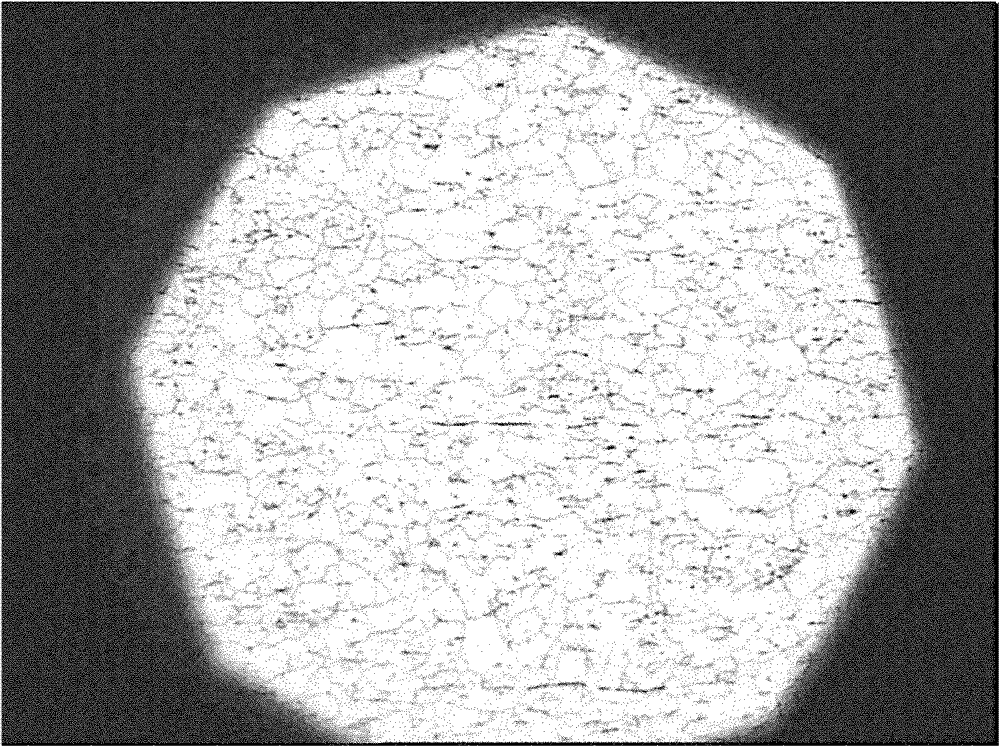

[0062] Raise the temperature of cold-rolled plain carbon steel with a width of 250mm, a thickness of 2.5mm, and a material of Q195L to 380°C, keep it warm for 2 hours, and continue to heat it up to 650°C. room temperature.

[0063] Take two samples respectively from the inside and outside of the upper, middle and lower steel coils to obtain 6 samples; take samples along the rolling direction of the samples to obtain samples respectively; after grinding and polishing the surfaces of the samples respectively, immerse them in Corrosion in 4% nital solution for 30 s, respectively observing the metallographic structure of the samples, and obtaining the metallographic structure diagrams of the samples respectively.

[0064] see Figure 16 , Figure 16 The metallographic structure diagram of the 200-fold magnification of the sample inside the upper steel coil provided by Example 1 of the present invention is obtained by Figure 16 It can be seen that its characteristics meet the r...

Embodiment 2

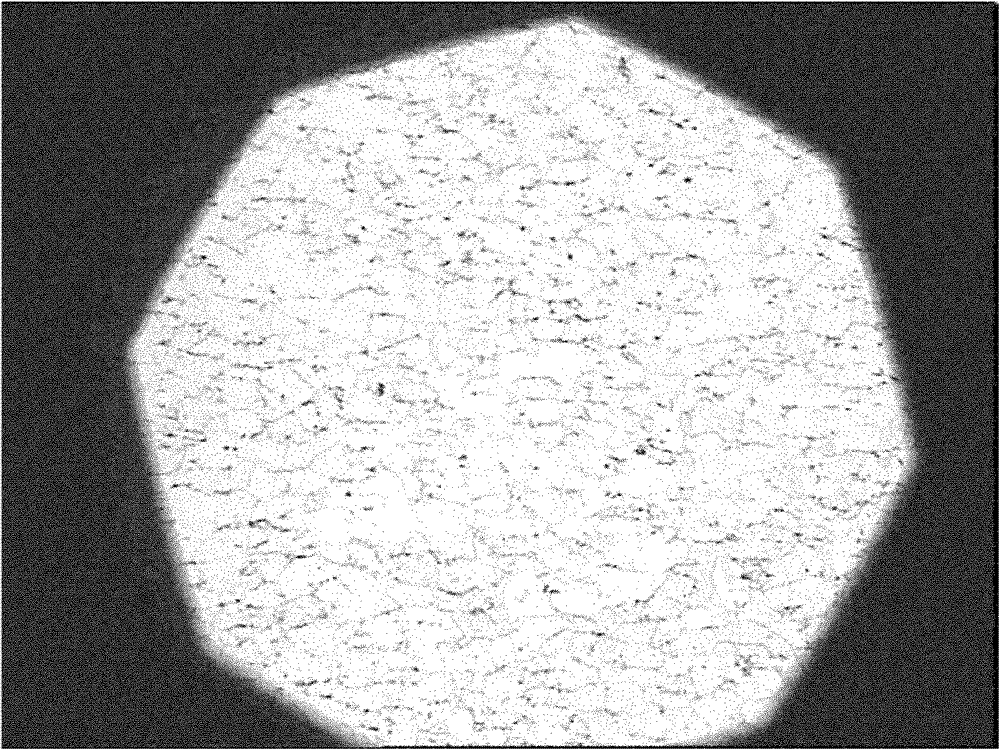

[0068] Heat the cold-rolled plain carbon steel with a width of 250mm, a thickness of 2.5mm, and a material of Q195L to 380°C, keep it warm for 2 hours, and continue to heat it up to 600°C. After 8 hours of heat preservation, air cooling for 2 hours, water cooling to 300°C, and then natural cooling to room temperature.

[0069] Take two samples respectively from the inside and outside of the upper, middle and lower steel coils to obtain 6 samples; take samples along the rolling direction of the samples to obtain samples respectively; after grinding and polishing the surfaces of the samples respectively, immerse them in Corrosion in 4% nital solution for 30 s, respectively observing the metallographic structure of the samples, and obtaining the metallographic structure diagrams of the samples respectively.

[0070] see Figure 17 , Figure 17 The metallographic structure diagram of the 200-fold magnification of the sample inside the upper steel coil provided by Example 2 of th...

Embodiment 3

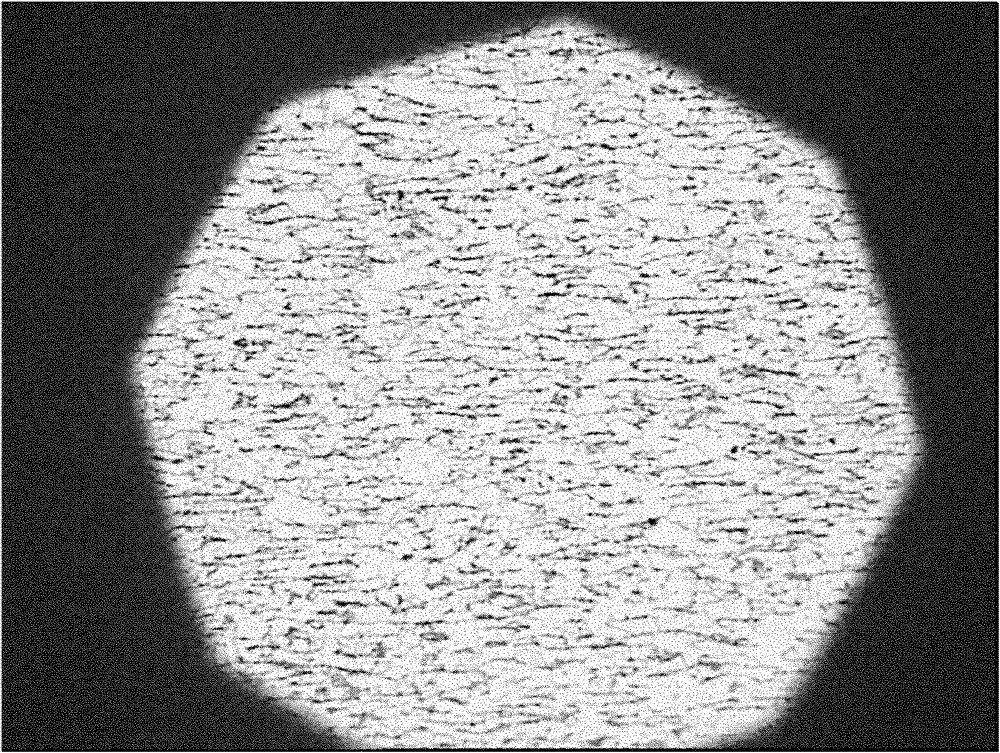

[0074] Raise the temperature of cold-rolled plain carbon steel with a width of 250mm, a thickness of 2.5mm, and a material of Q195L to 380°C, keep it warm for 2 hours, and continue to heat it up to 700°C. room temperature.

[0075] Take two samples respectively from the inside and outside of the upper, middle and lower steel coils to obtain 6 samples; take samples along the rolling direction of the samples to obtain samples respectively; after grinding and polishing the surfaces of the samples respectively, immerse them in Corrosion in 4% nital solution for 30 s, respectively observing the metallographic structure of the samples, and obtaining the metallographic structure diagrams of the samples respectively.

[0076] see Figure 18 , Figure 18 The metallographic structure diagram of the magnified 200 times of the sample inside the upper steel coil provided by Example 3 of the present invention is obtained by Figure 18 It can be seen that its characteristics meet the requ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com