Optical disc drive

A technology of optical disc drive and optical disc, which is applied in the direction of driving/moving the recording head, recording/reproducing with optical methods, and instruments, etc. It can solve problems such as out-of-step and creeping gears, and achieve the elimination of creeping gears or out-of-steps and high reliability , the effect of stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

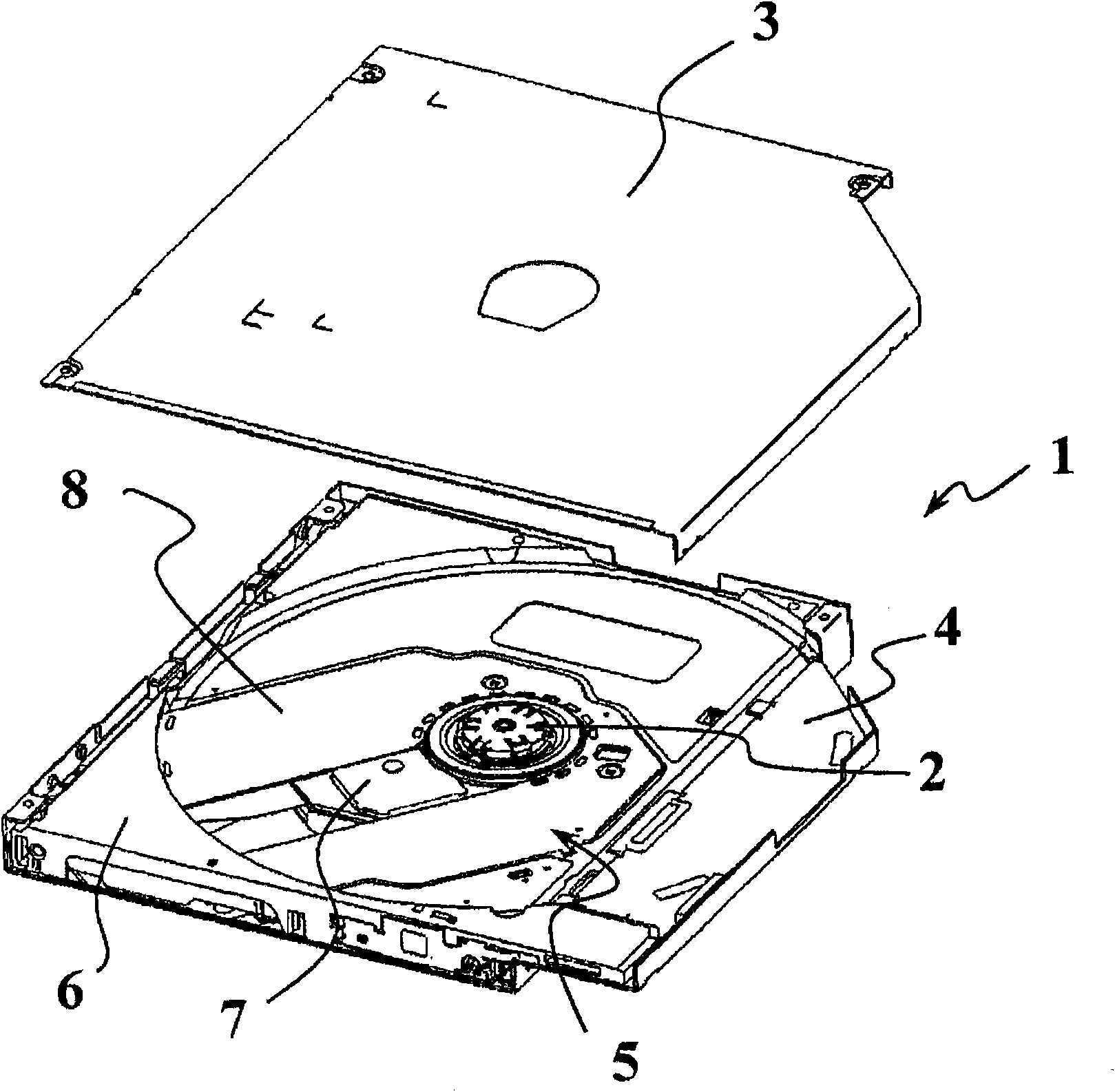

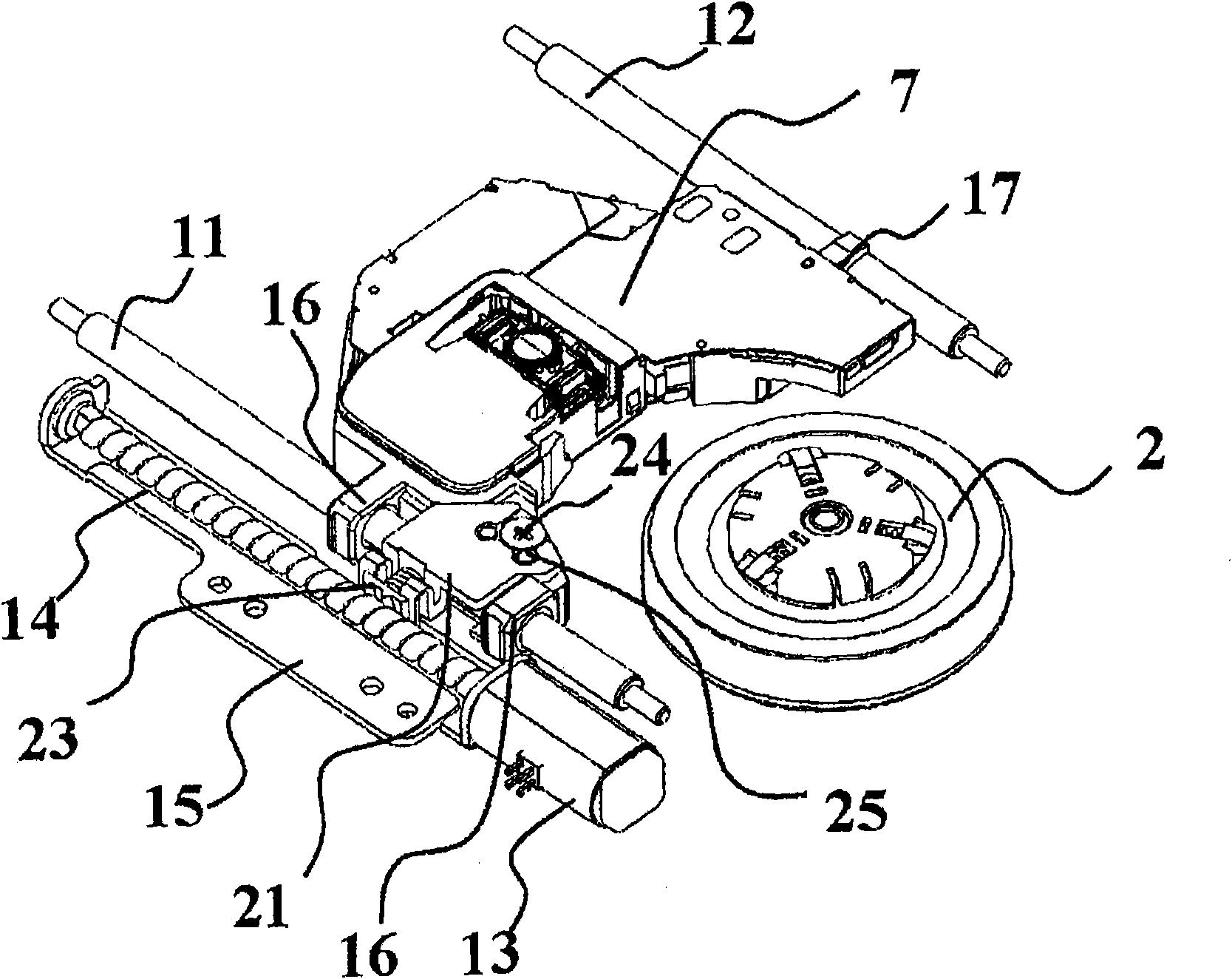

[0052] First, the configuration of an optical disk drive device 1 according to an embodiment of the present invention will be described.

[0053] figure 1 It is an exploded perspective view of the optical disk drive device 1 of this embodiment.

[0054] exist figure 1 Among them, the optical disk drive device 1 is a device for recording and reproducing information on a recording surface of a recording medium (hereinafter referred to as a disk) such as a CD, DVD, or BD (Blu-ray Disc) having a diameter of 120 mm and a thickness of 1.2 mm.

[0055] The optical disk drive device 1 that is the object of the present invention is a thin box-shaped device with a width of 130 mm, a depth of 130 mm, and a device thickness of 12.7 mm (or 9.5 mm), and is called a thin type and is equipped in a mobile personal computer. (or ultra-thin) optical disc drive device 1 of the drive.

[0056] The optical disk drive device 1 is constituted by a case formed by assembling a top cover 3 and a bott...

Embodiment 2

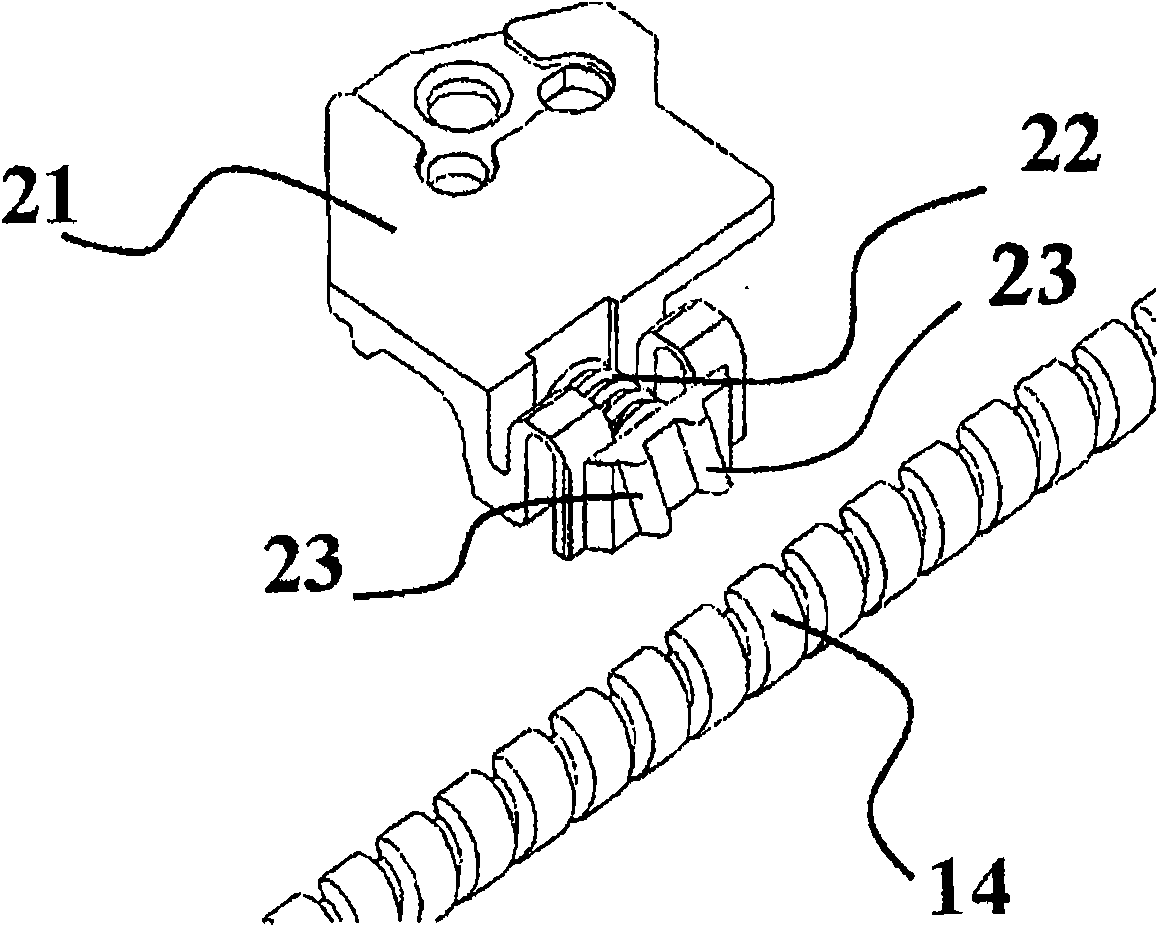

[0087] use Figure 7 The case of Example 2 of the present invention will be described.

[0088] Figure 7 It is a figure showing the structure of the guide feeder which has 2nd Example of this invention.

[0089] exist Figure 5 In the structure of the first embodiment shown, there is a groove structure 31 between the two tooth portions 23 of the guide feeder 21, and the groove structure 31 is formed as a curved portion with respect to the two tooth portions 23. The initial bending deformation structure.

[0090] Figure 7 (a) is an example in which the groove structure 31 is applied between the two tooth portions 23 of the guide feeder 21 and on the side of the helical gear 14 . In this embodiment, the curved structure is such that the groove portion 31 is located inside.

[0091] Accordingly, when the guide feeder 21 presses the helical gear 14 , the bending portion is deformed to open by the pressing force, and the two tooth portions 23 apply a pressing force toward t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com