Separating device for separating particles able to be magnetized and particles not able to be magnetized transported in a suspension flowing through a separating channel

A separation channel and separation device technology, applied in magnetic separation, solid separation, high-gradient magnetic separation, etc., can solve problems such as inability to ensure separation, small magnetic field gradient/magnetic field strength, etc., and achieve the effect of improving separation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

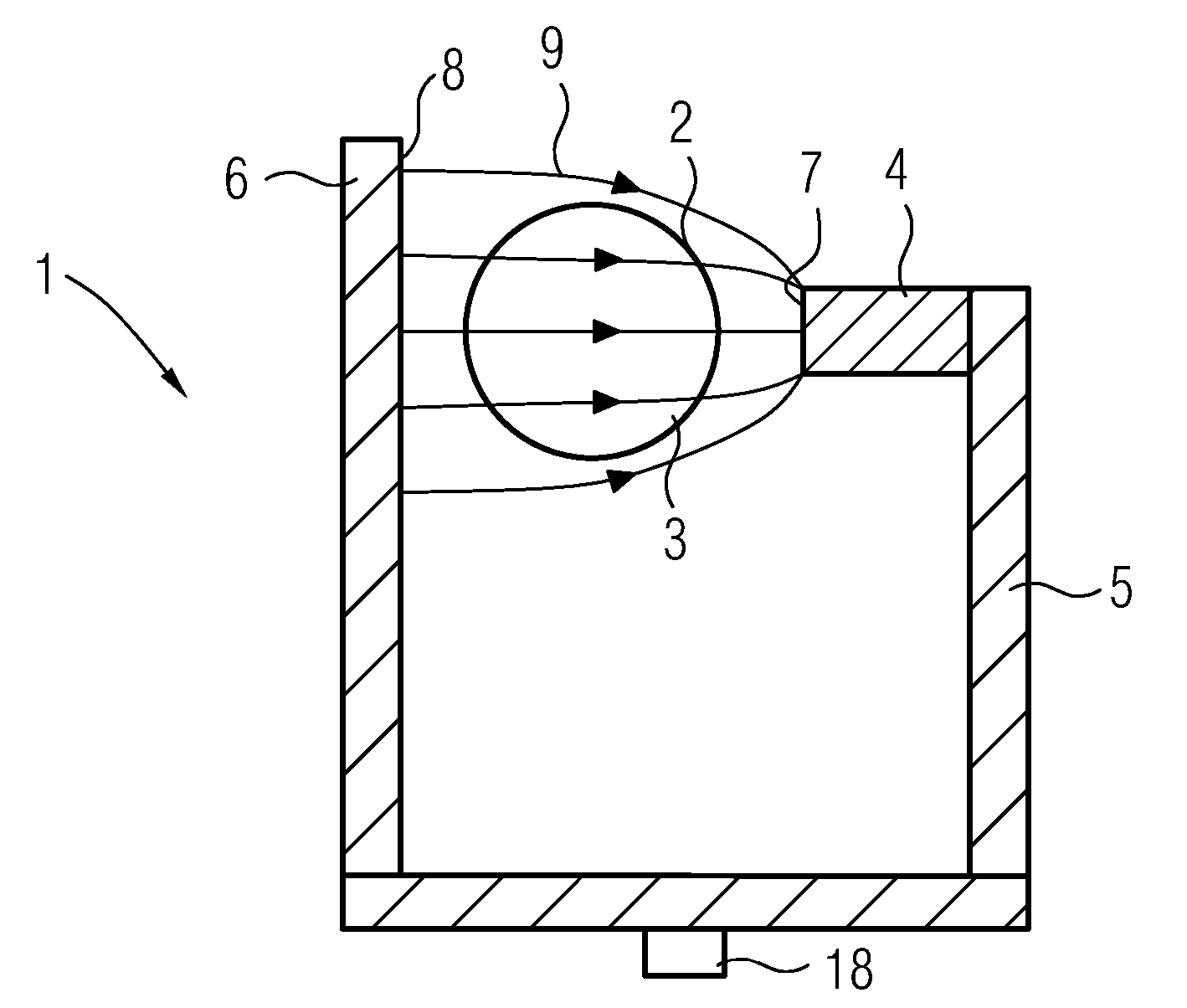

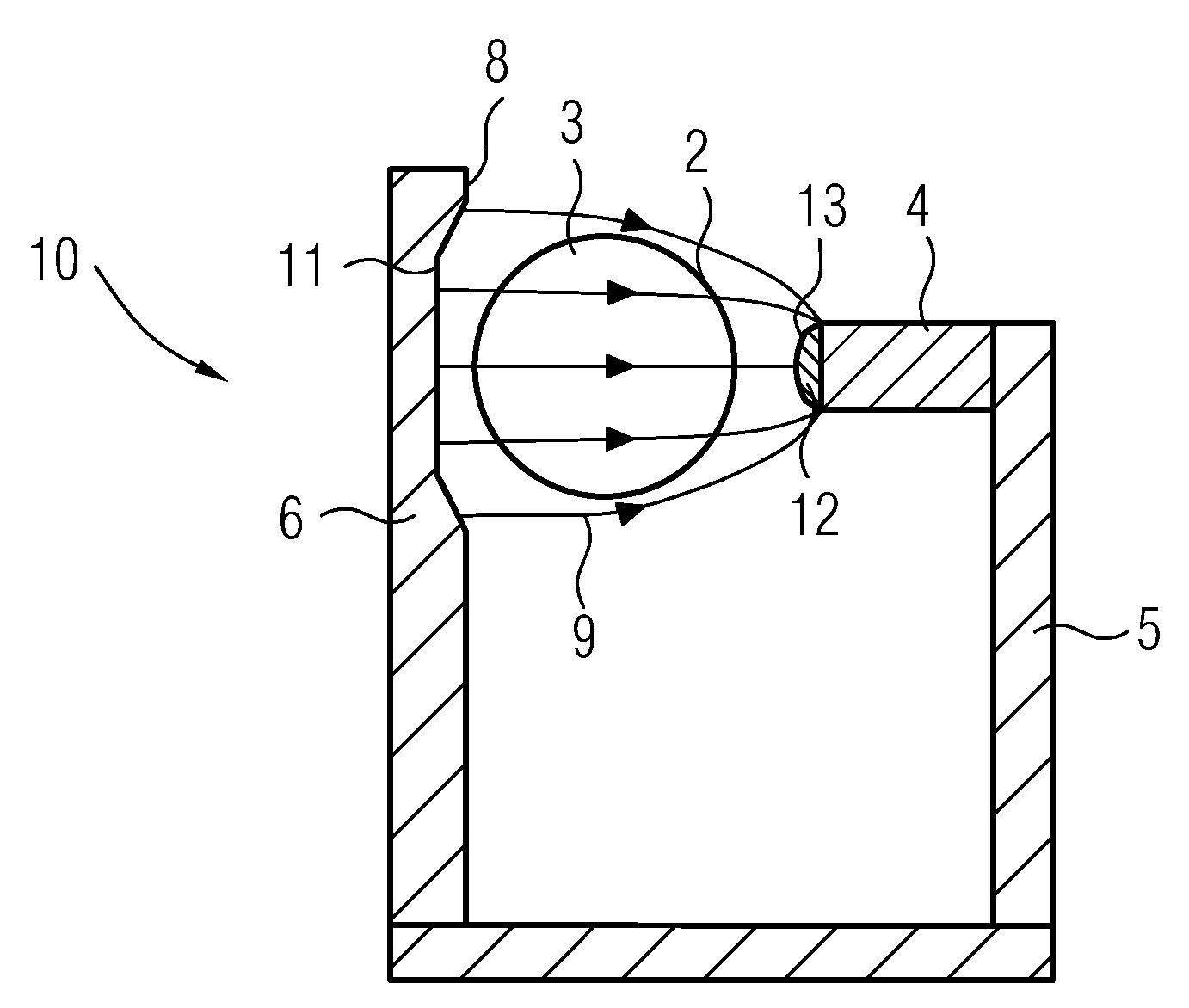

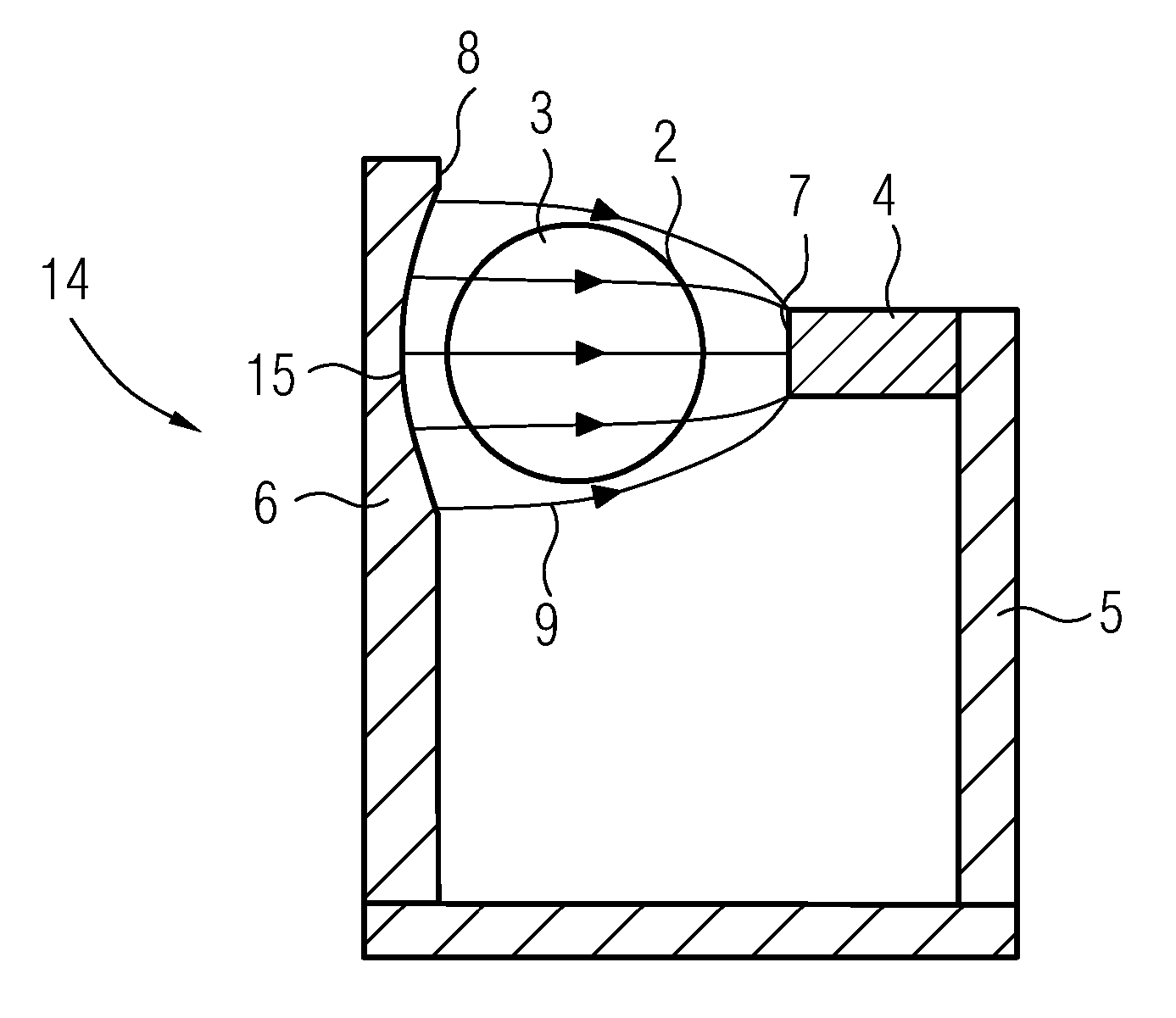

[0023] figure 1 A schematic sketch of the essential components of the separating device 1 according to the invention is shown. The separation device comprises a duct 2 extending perpendicular to the plane of the drawing, which defines a separation channel 3 equipped with a suspension containing magnetizable and non-magnetizable particles. The task of the separating device 1 is to allow the separation of magnetizable and non-magnetizable particles. For this purpose, a permanent magnet 4 is provided which is arranged on one side of the separation channel 3 , by means of which a deflection magnetic field is to be generated which deflects the magnetizable particles towards the side of the permanent magnet 4 . It should be noted here that instead of one permanent magnet 4 a plurality of permanent magnets connected in series can also be provided.

[0024] In order to optimize the magnetic field behavior inside the separating channel 3 and to improve the magnetic field strength, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap