A six-channel fusion extrusion nozzle for a stacked color 3D printer

A three-dimensional printer, stacking technology, applied to the printing machine with six-channel poly-melting extrusion nozzle belongs to a stacked color field, can solve the problems of unusable, low mechanical strength, etc., achieve energy saving efficiency improvement, eliminate assembly and The effect of troublesome leveling and improved utilization of heat efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

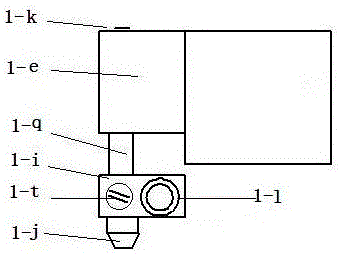

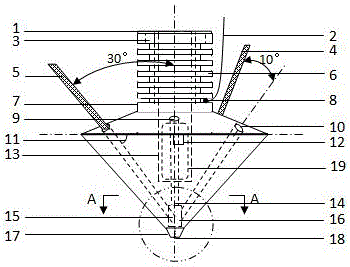

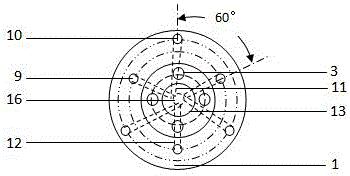

[0025] Six-inlet single-outlet nozzle substrate ( diagram 2-1 ) is an alloy copper metal body with high thermal conductivity, and the structure is arranged as a cylinder connected to the bottom of a truncated cone, and a heating chamber ( diagram 2-1 3), the bottom and the melting and mixing mixing chamber ( diagram 2-1 6) The bottom is connected; the substrate of the six-inlet and single-outlet nozzle passes through the four fixing screw holes set on the upper end of the heating chamber ( Figure 2-3 ) are connected to the X and Y travel brackets, and the fixing screw holes are penetrated to the heat dissipation wing base ( figure 2 -7) On the upper plane, set the cooling fins ( figure 2 -6) To reduce the heater ( diagram 2-1 9) The released heat is uploaded to the X and Y walking brackets; the other two symmetrical fixing screw holes are heaters and temperature sensors ( figure 2 -8) Fixed setting; the wire feeding channel is set to φ1.9mm, and the entrance ( fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap