Battery and battery pack

A technology of battery packs and batteries, which is applied in the manufacture of battery pack components, secondary batteries, and secondary batteries, and can solve the problem that battery heat cannot be effectively discharged and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

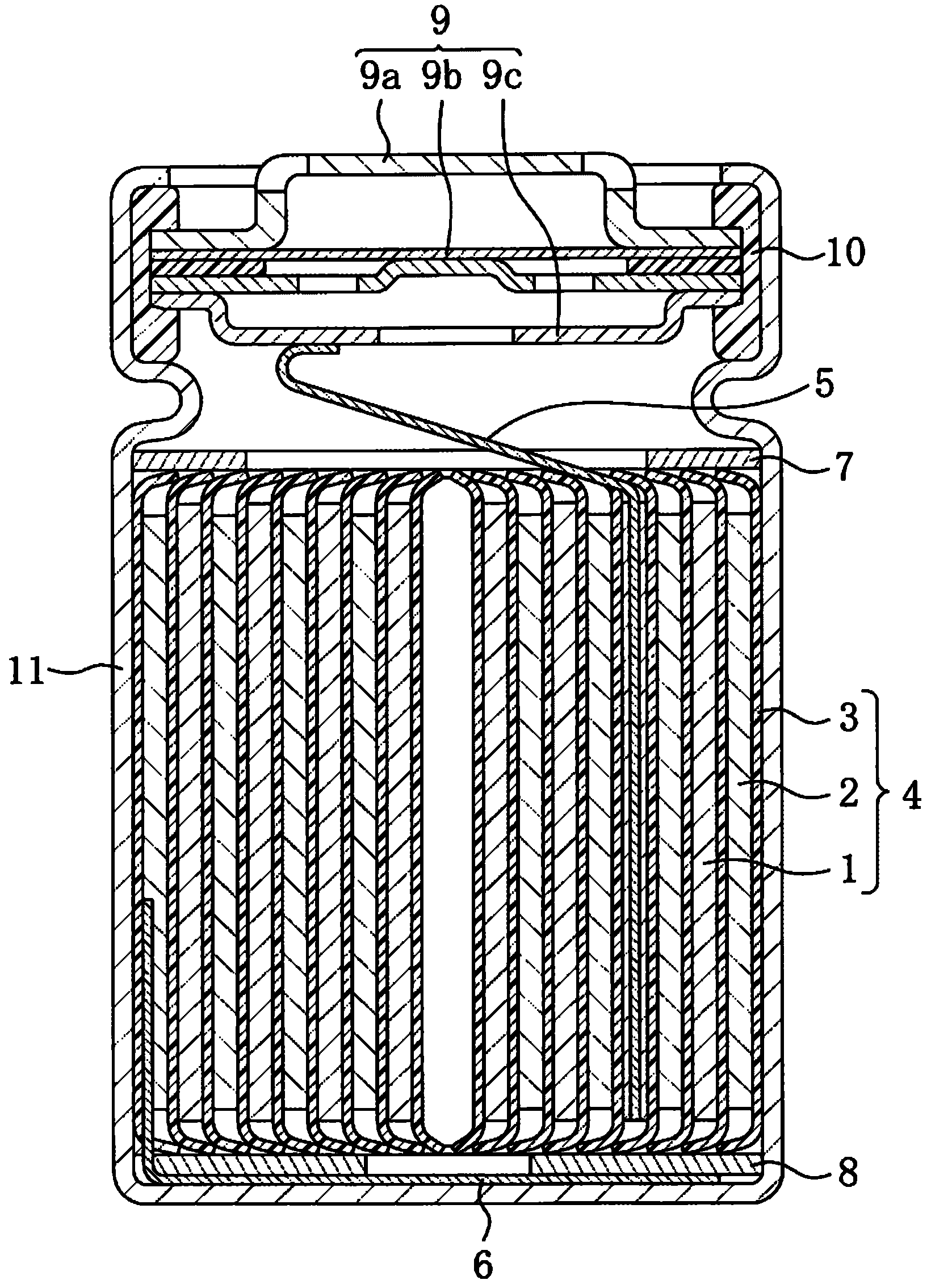

[0082] Hereinafter, for the battery of the first embodiment of the present invention, refer to figure 1 In the description, a cylindrical lithium-ion secondary battery is taken as an example of the battery. figure 1 It is a cross-sectional view showing the structure of the battery according to the first embodiment of the present invention.

[0083] Such as figure 1 As shown, the electrode group 4 is housed in a bottomed cylindrical battery case 11 together with the non-aqueous electrolytic solution. An annular upper insulating plate 7 is disposed on the upper portion of the electrode group 4 , and an annular lower insulating plate 8 is disposed on the lower portion of the electrode group 4 . The opening of the battery case 11 is caulked to the peripheral edge of the sealing plate 9 via the gasket 10 , whereby the opening of the battery case 11 is sealed.

[0084] The electrode group 4 is formed by winding the positive electrode plate 1 and the negative electrode plate 2 bet...

no. 2 Embodiment approach

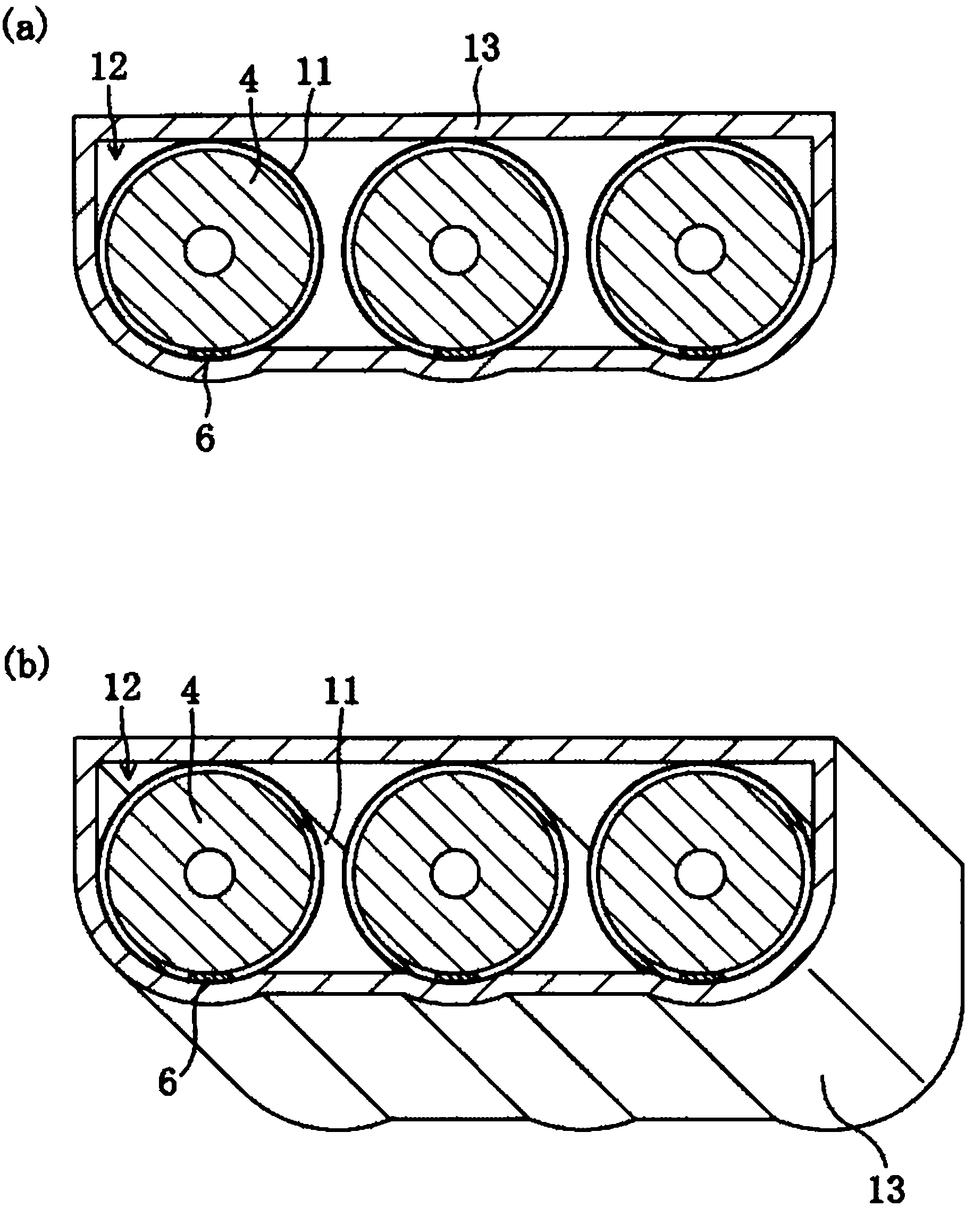

[0097] Hereinafter, for the battery pack according to the second embodiment of the present invention, refer to figure 2 (a) to (b) will be described. figure 2 (a) to (b) are diagrams showing the configuration of the battery pack according to the second embodiment of the present invention, specifically, figure 2 (a) is a sectional view, figure 2 (b) is a sectional perspective view.

[0098] The battery pack of this embodiment is a battery pack in which the battery 12 of the first embodiment is enclosed in a battery pack case 13 .

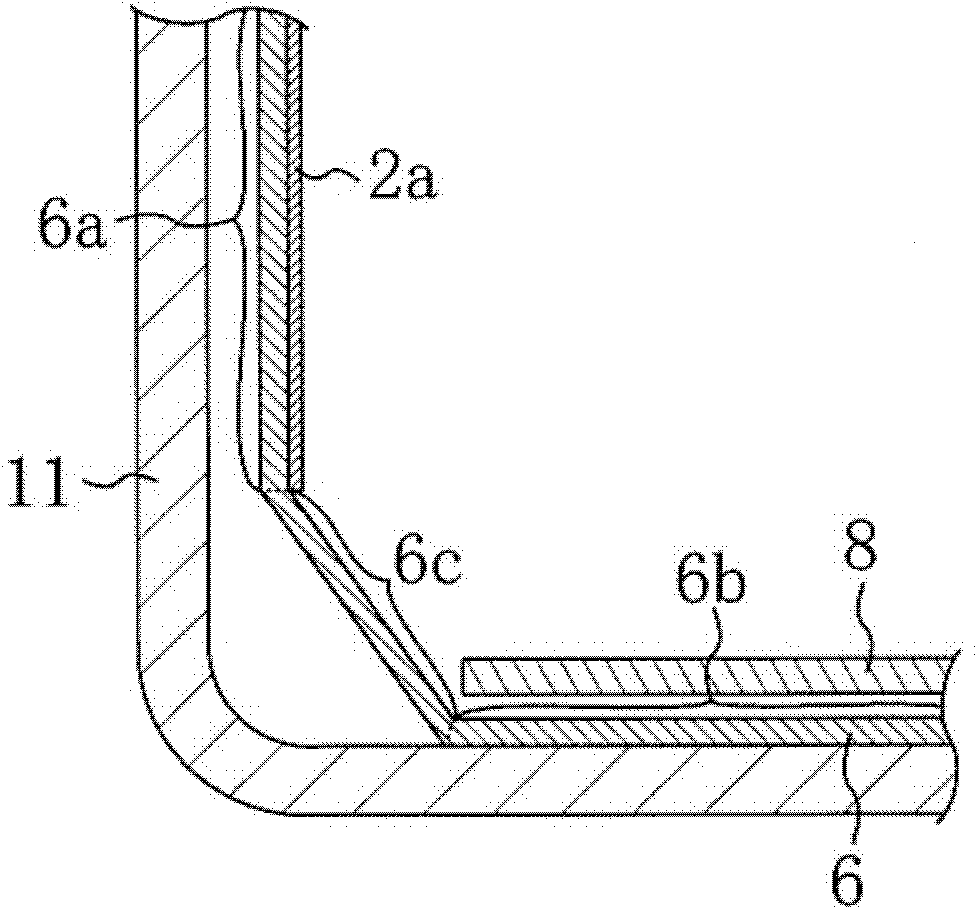

[0099] Such as figure 2 As shown in (a) to (b), the battery 12 is arranged in the battery pack case 13 based on the position of the negative electrode internal lead 6 judged by the display means. Specifically, the part of the outer surface of the battery case 11 corresponding to the inner lead 6 for the negative electrode, in other words, one end of the inner lead 6 for the negative electrode of the battery case 11 (refer to image 3 : 6a) ...

Embodiment 1

[0199] Hereinafter, for the manufacturing method of the battery of Example 1, refer to figure 1 Be explained.

[0200] (1) Production of positive plate

[0201] In 100 parts by weight of lithium cobaltate (LiCoO) with an average particle size of 10 μm as the positive electrode active material 2 ), 8 parts by weight of PVdF as a binder, and 3 parts by weight of acetylene black as a conductive agent, add an appropriate amount of N-methyl-2-pyrrolidone (NMP) and mix to obtain a positive electrode mixture paste.

[0202] Then, on both faces of the positive electrode current collector made of a strip-shaped aluminum foil with a length of 600 mm, a width of 54 mm, and a thickness of 20 μm, remove the central part of the positive electrode current collector (that is, the positive electrode is connected with the inner lead). The positive electrode mixture paste was applied to the portion other than the exposed portion of the positive electrode current collector. Thereafter, the pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com