Shoe

A synthetic resin and foam technology, applied in the field of shoes, can solve problems such as difficulty in running, difficulty in walking, and no elasticity, so as to prevent deformation and expand the selection range of blank materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

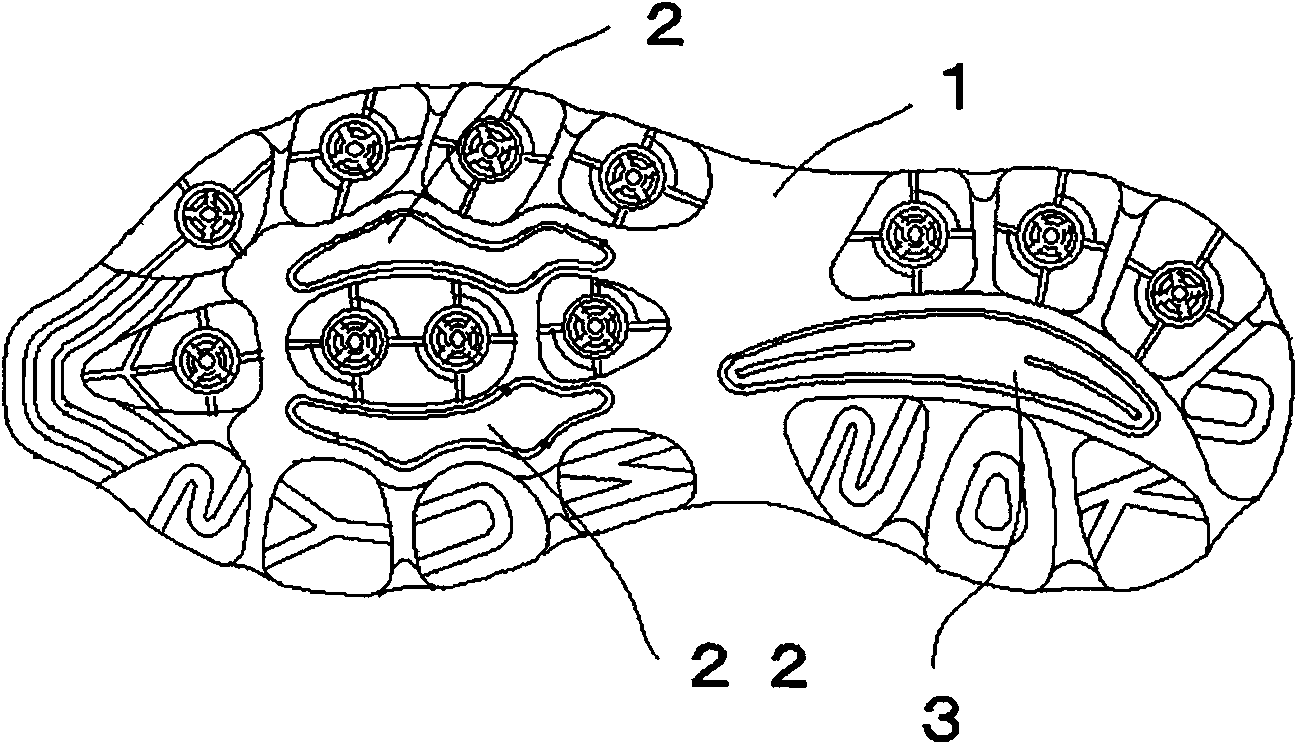

[0030] The shoe of the present invention is a shoe having a sole formed of a synthetic resin foam, and is characterized in that at least one plate is provided on the ground-contacting side of the sole 1 from the front of the non-stepping part to the toe part including the curved part. The rigidity and elasticity of the board are higher than that of the synthetic resin foam constituting the sole. For example, like figure 1 As shown, the two plates 2 , 22 are provided at bilaterally symmetrical positions on the longitudinal centerline of the sole in the region from the front of the non-pedal portion to the toe portion including the curved portion.

[0031] The shoe of the present invention having a sole made of a synthetic resin foam is a type in which the entire sole is made of a synthetic resin foam. In the case of a shoe sole made of a midsole and an outsole, at least the midsole is made of a synthetic resin foam.

[0032] As the above-mentioned synthetic resin foam, if it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com