Welding supporting table for joints

A technology for supporting tables and loading parts, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low operating efficiency, complex structure, high cost, etc., and achieve high efficiency, firm and stable support , Improve the effect of supporting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

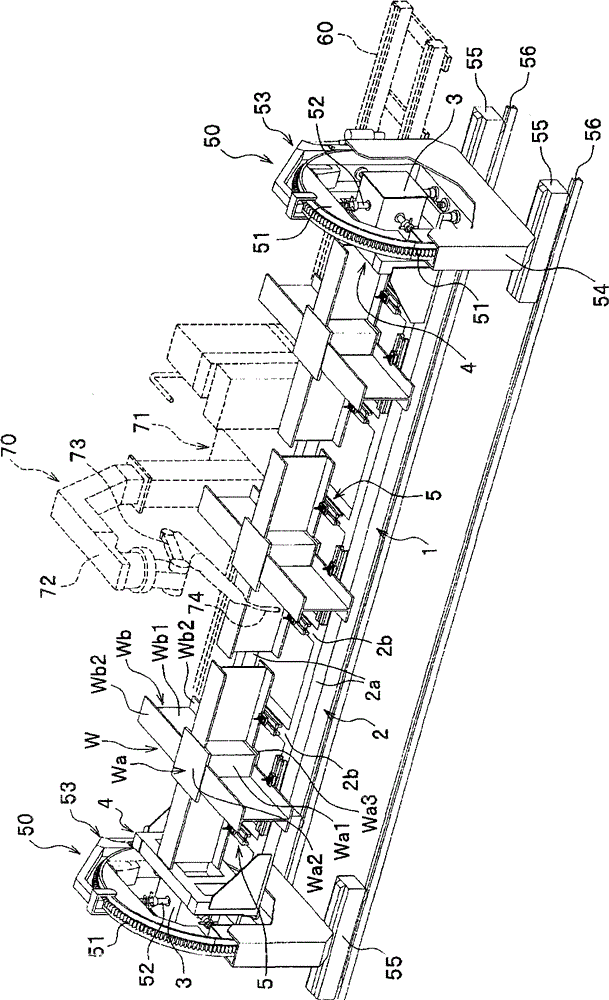

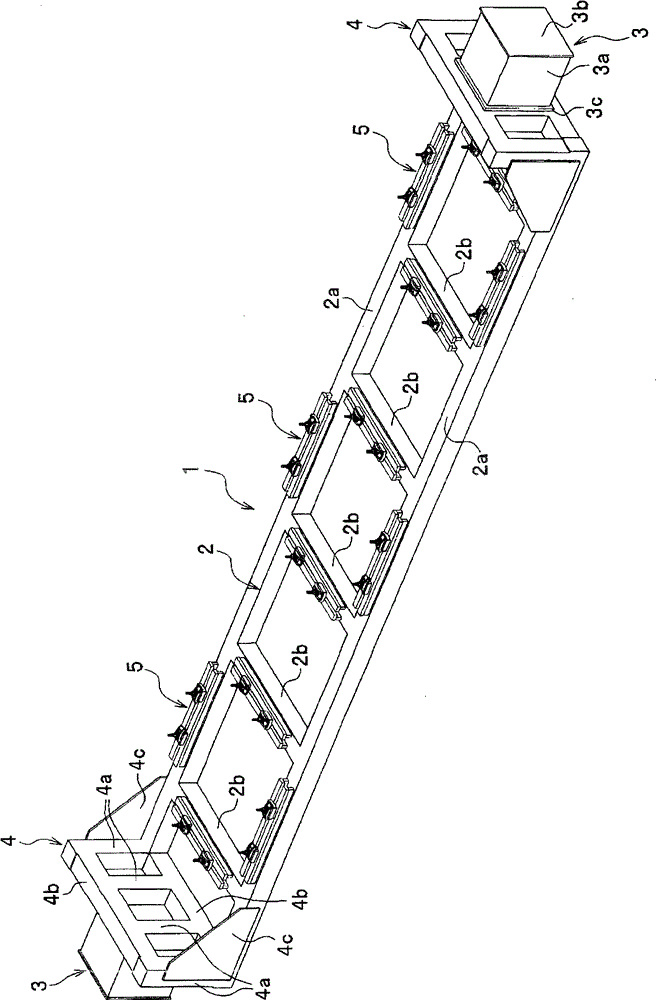

[0037] Such as figure 1 As shown, the joint welding support table 1 supports a plurality of (here, three) joints W, which are held between the existing rotary indexers 50 and 50 for use. In addition, the existing welding device 70 is installed at the same time along the direction spanning between the rotary indexers 50 and 50.

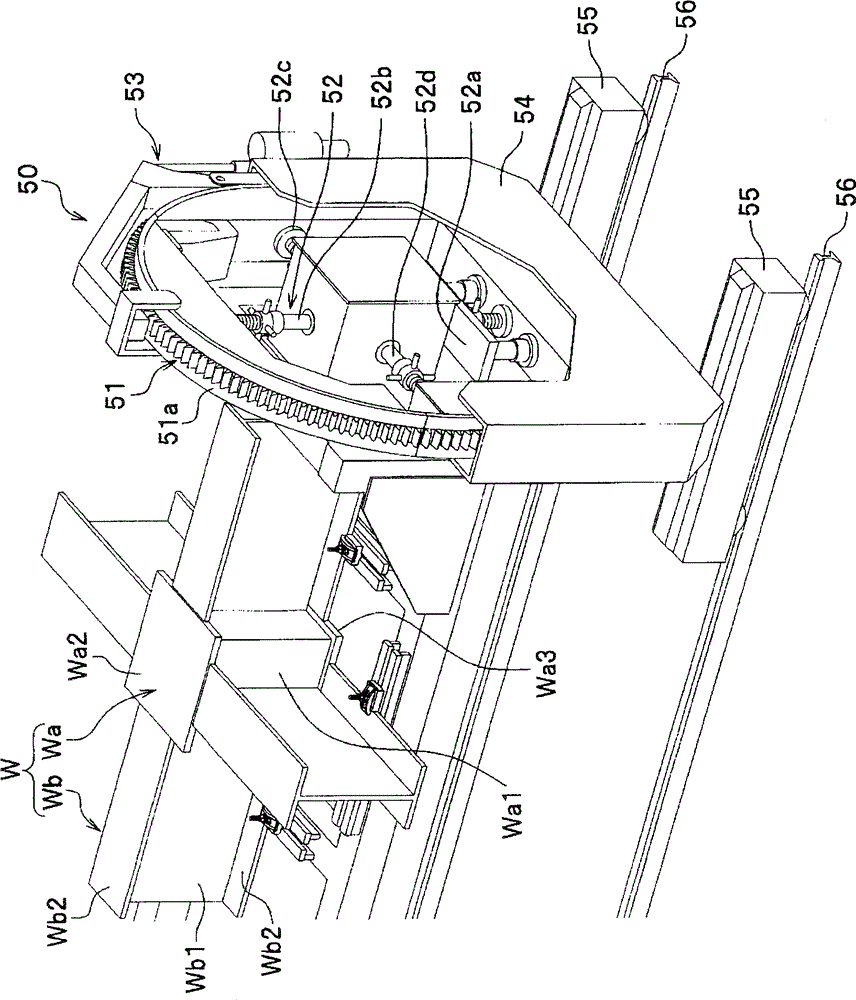

[0038] Rotary indexers 50 and 50 are devices with existing structures that hold the workpiece or joint welding support table 1 to be welded, and remove the held workpiece or joint welding support table 1 according to a preset procedure. The basic position rotates by a predetermined angle or moves on the moving rail 56 for the positioner, so that the workpiece or the welding support table 1 for joints is slidably moved. In addition, the structure of the rotary indexers 50 and 50 is as follows: figure 1 As shown, a fixing jig 52 that is held...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com