Film sticking equipment and film sticking process using same

A film sticking equipment and film sticking technology, applied in the direction of layered products, lamination devices, lamination, etc., can solve the problems of increased cost, low product yield, affecting product appearance, etc., to improve appearance, improve product yield, increase The effect of the success rate of the filming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described below in conjunction with the accompanying drawings.

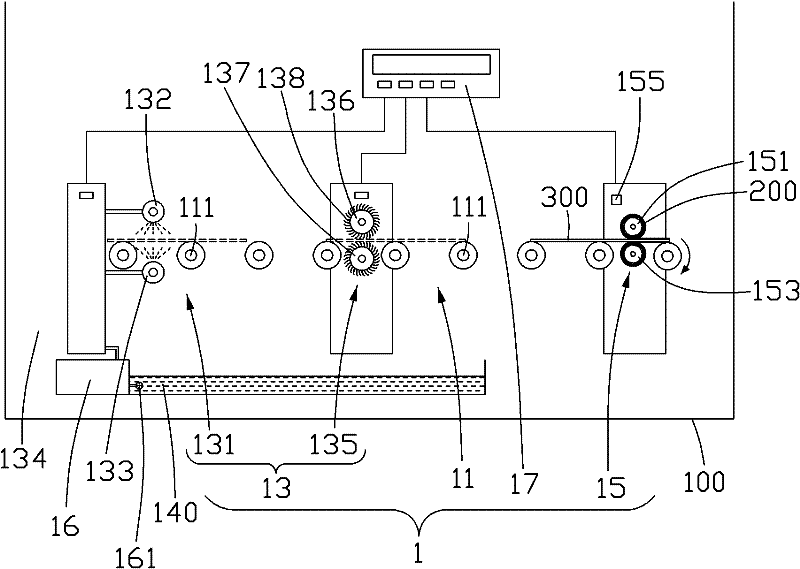

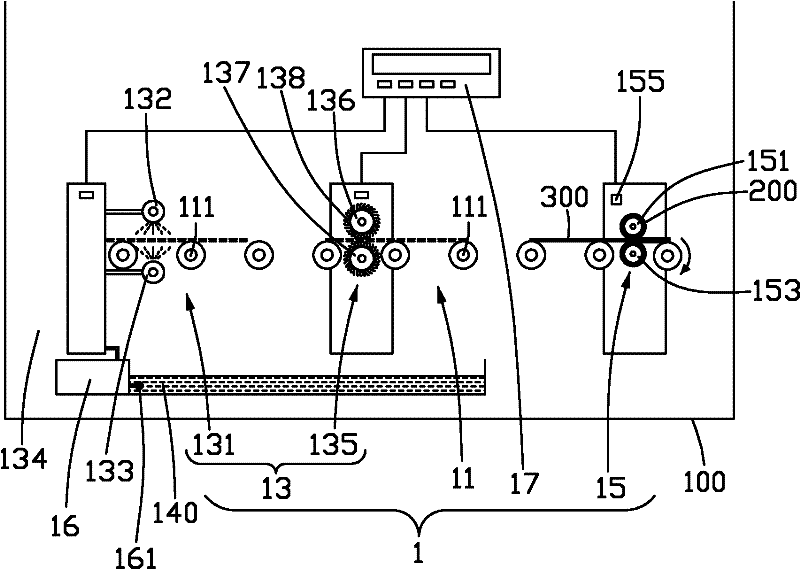

[0015] The embodiment of the present invention provides a film sticking device. Please refer to the attached drawing, which is a functional structural diagram of a preferred embodiment of the film sticking device of the present invention. The film body 200 and the printed circuit board 300 to be laminated are provided to the film sticking equipment 1 , and the film body 200 is pressed onto the surface of the printed circuit board 300 through the film sticking device 1 .

[0016] The film sticking equipment 1 includes a box body 100 , a conveying device 11 , a liquid spraying device 13 , a lamination device 15 and a control system 17 . The box 100 includes a storage space for accommodating the conveying device 11 , the liquid spraying device 13 , the lamination device 15 and the control system 17 therein. The film body 200 is disposed on the laminating device 15 . The control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com