Spinning apparatus for producing fine threads by splicing

A spinning device and spinning technology, used in textile, stretch spinning, textile and papermaking, etc., can solve problems such as low output and achieve the effect of easy maintenance and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

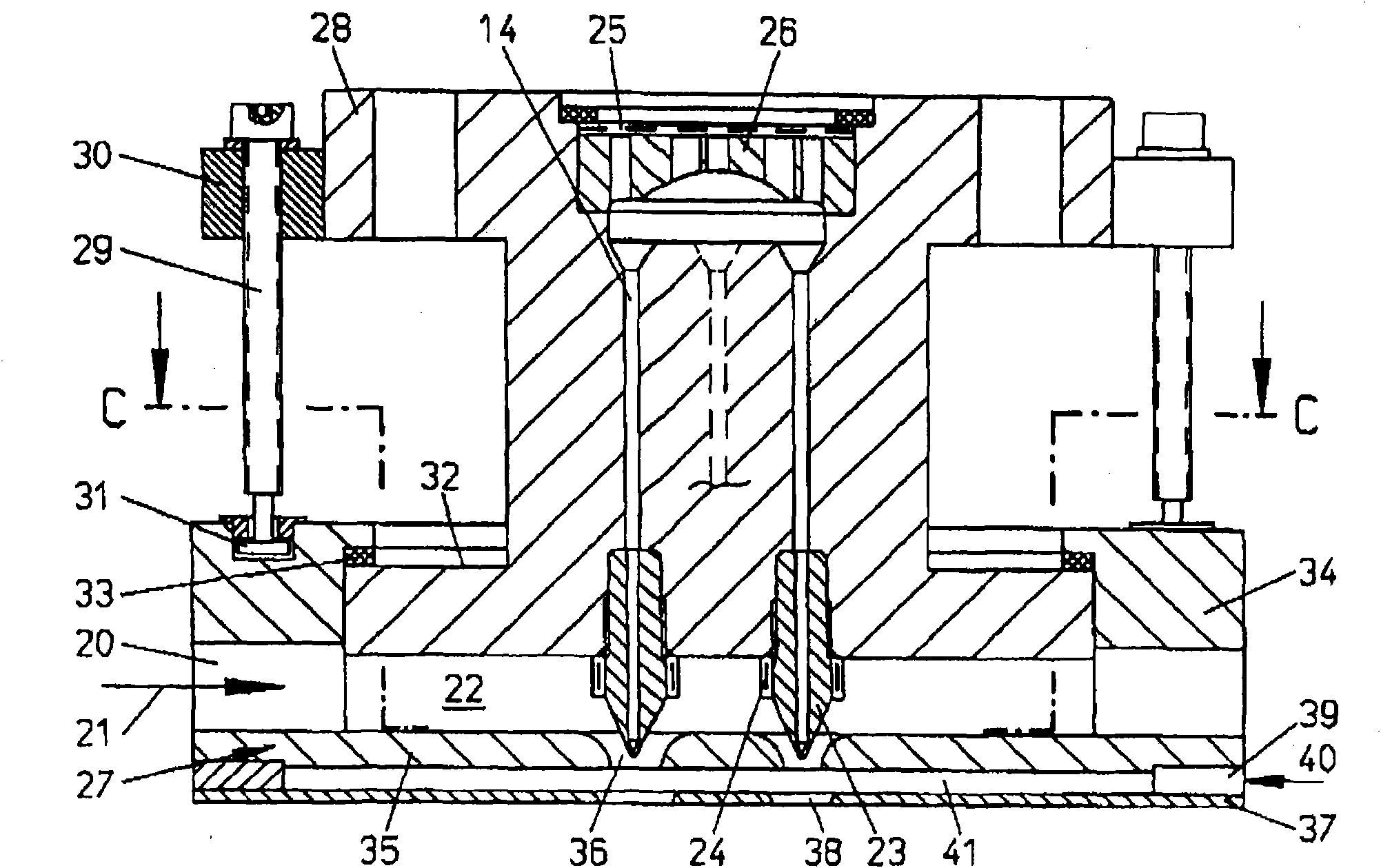

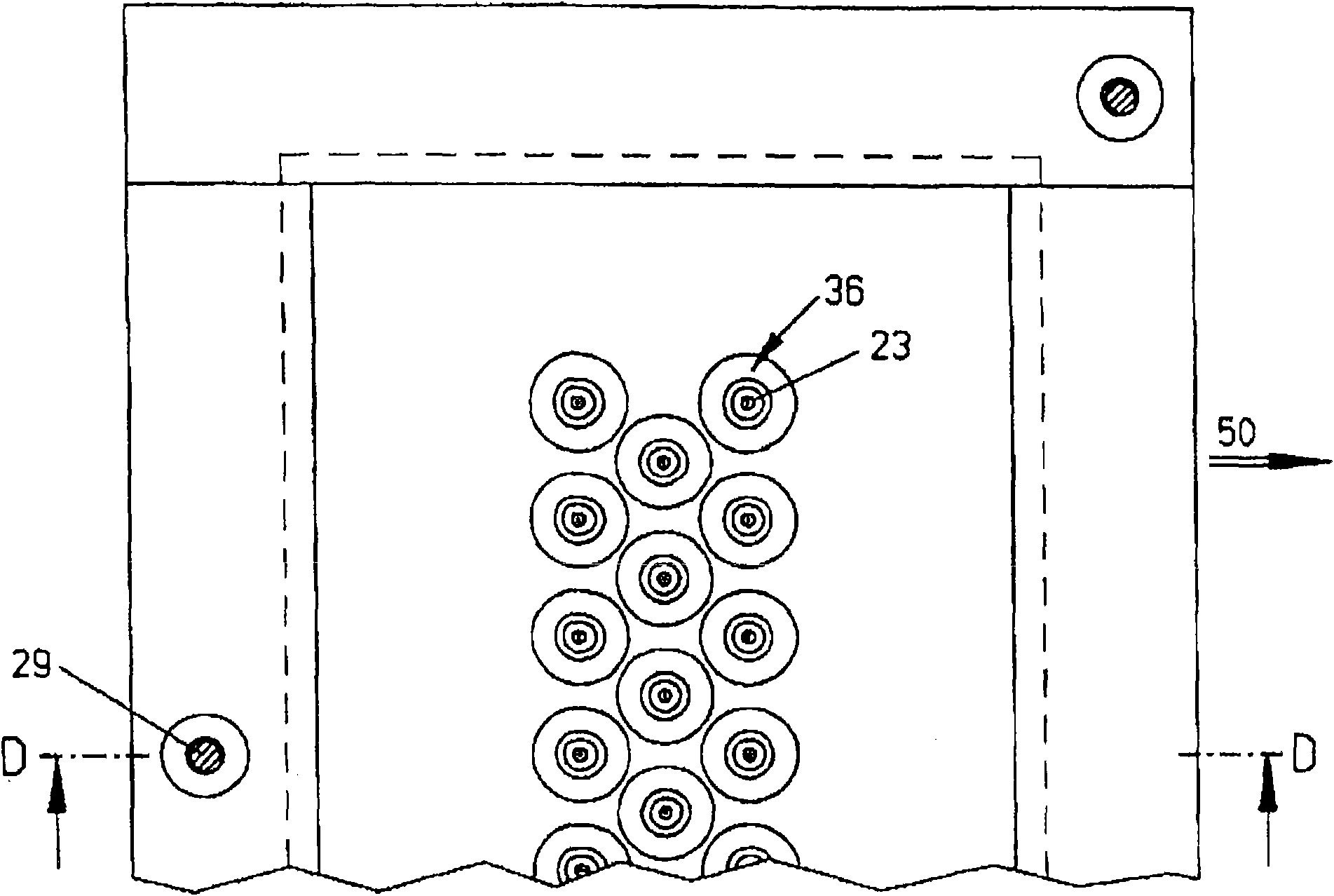

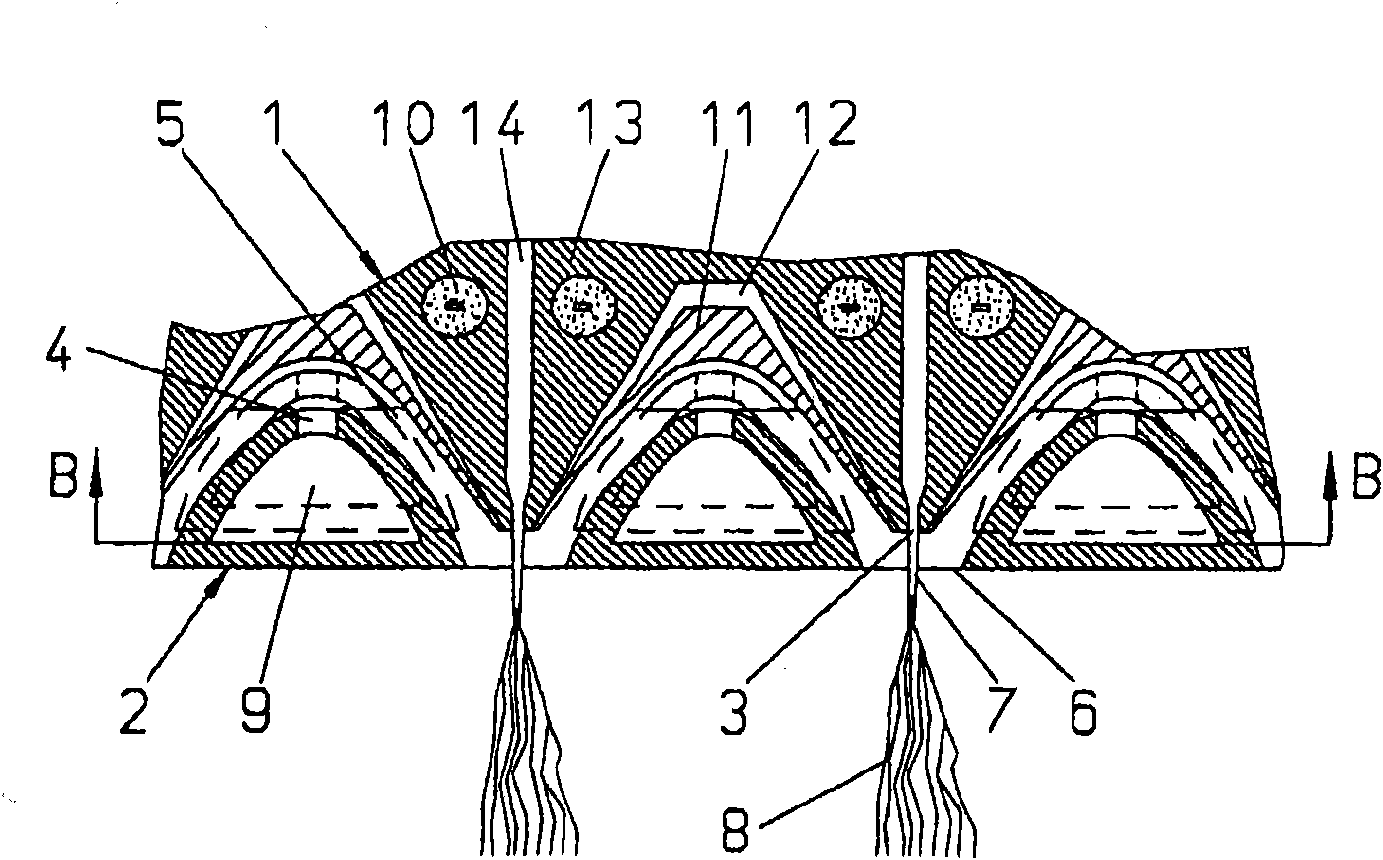

[0022] figure 1 with 2 The represented spinning device has a spinning nozzle part 28 in which a plurality of melt channels 14 are arranged, the above-mentioned melt channels being provided by means of a filter 25 and a perforated plate 26 for dispensing in the melt or In the case of a solution, the supplied melt or solution is purified. The melt channels continue into spinning nozzles or spinning nozzle sockets 23 , only three rows of spinning nozzle sockets 23 are shown here. A plurality of spinning nozzle connectors 23 can be arranged very perfectly one behind the other in the direction of progression of the arrow 50 .

[0023] The lower plate-shaped region of the spinning nozzle section is accommodated in a gas nozzle section 27 comprising a frame-like piping 34 and a plate-like section 35 in which three rows of respectively offset Laval nozzles 36 are arranged , the three rows of Laval nozzles 36 correspond to the rows of spinning nozzle pipe joints 23 . The piping por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com