Precipitation construction method employing pipe embedded in deep foundation pits

A construction method and technology for deep foundation pits, applied in infrastructure engineering, construction and other directions, can solve problems such as hidden dangers of underground engineering waterproofing, affecting the progress of the construction period, wasting groundwater resources, etc., so as to shorten the construction period, improve the waterproof effect, and reduce engineering costs The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

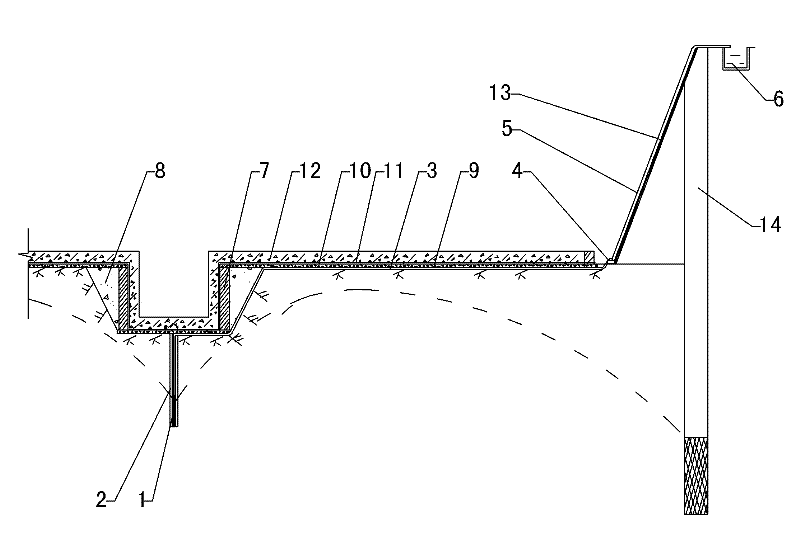

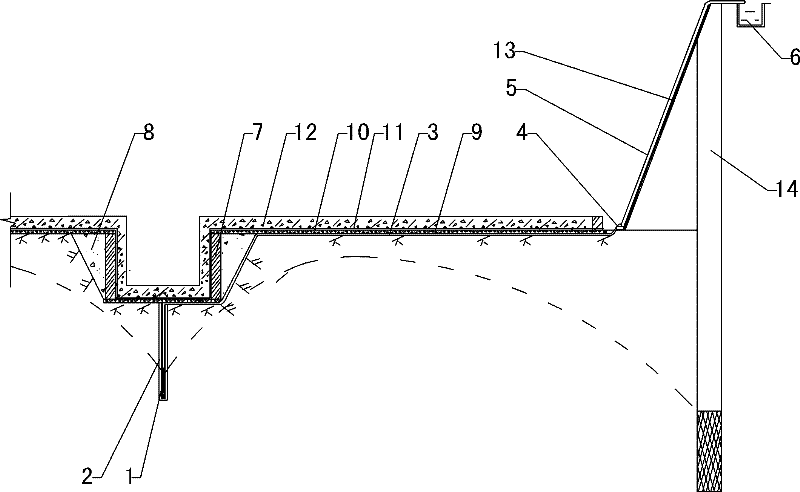

[0020] Refer to attached figure 1 :

[0021] The deep foundation pit buried pipe dewatering construction method comprises the following steps,

[0022] a. According to the engineering drawings and geological conditions, excavate the foundation pit. When the earthwork is excavated to 1m above the design bottom elevation of the engineering foundation pit, the position of the elevator pit or sump pit to be dug is accurately measured, and the excavator is used in the middle of the foundation pit. Dig a pit reaching 100mm below the level of the bottom of the foundation pit as an elevator pit or sump;

[0023] b. Use an excavator to vertically press a section of steel pipe with a diameter of 100mm into the middle of the elevator pit or sump, then take out the steel pipe to form a vertical wellbore with a diameter of 100mm, and then vertically install the PVC filter pipe 1 Installed in the wellbore, the diameter of the PVC filter pipe 1 is 40mm;

[0024] c. Fill the gap between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com