Dye spin-coating apparatus for DVDR optical discs

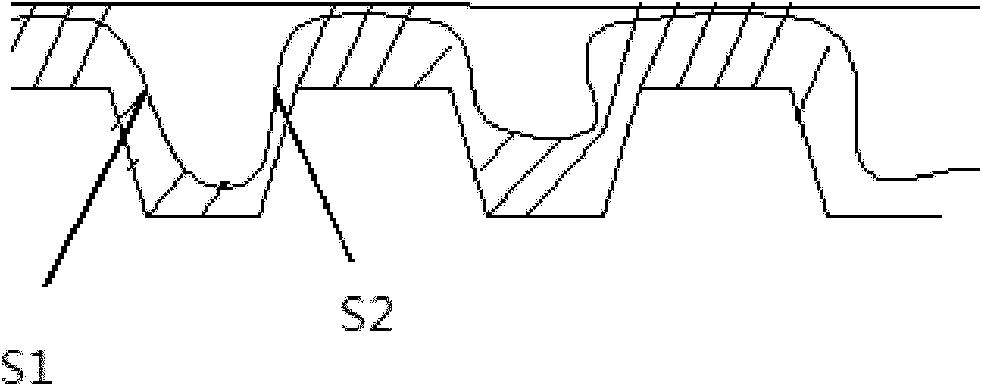

A technology for dyes and optical discs, which is applied to devices and coatings that apply liquid to the surface. It can solve problems such as data deviation, affecting spot focusing and tracking, and tracking errors, shortening time, improving production efficiency, and reducing grooves. The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be given below in conjunction with the accompanying drawings, and will be described in detail, so that the functions and characteristics of the Blu-ray disc glue spin coating device of the present invention can be better understood.

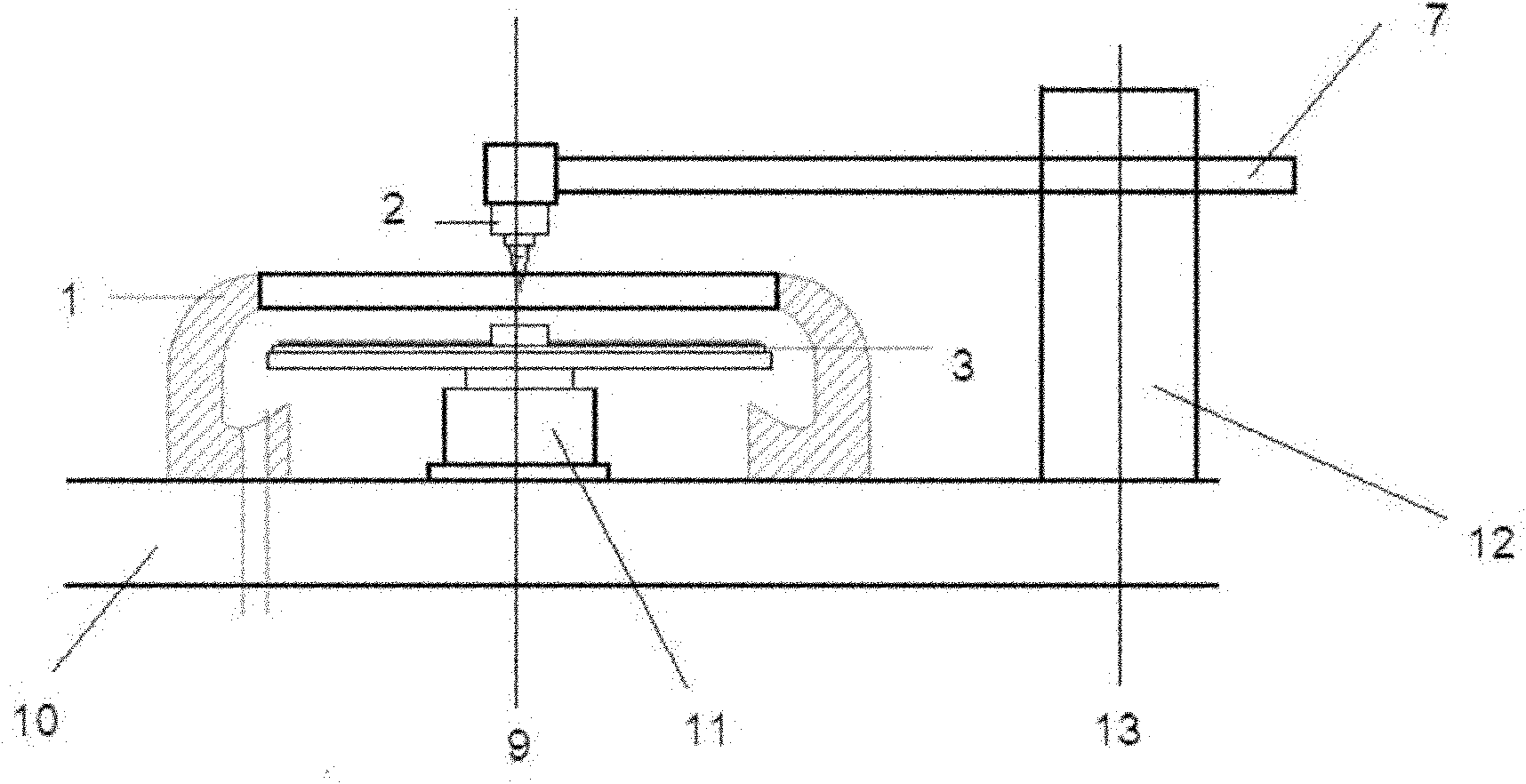

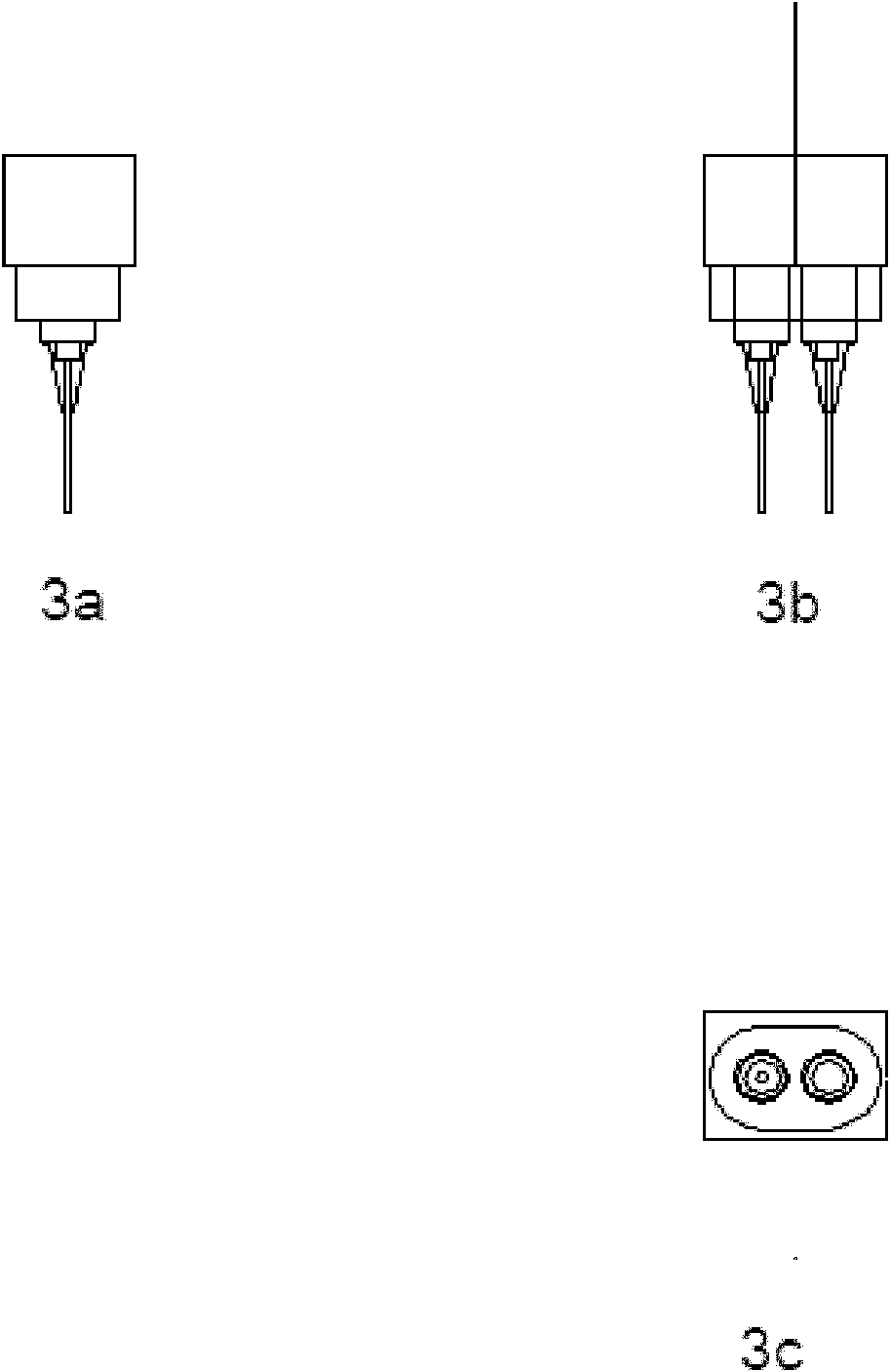

[0022] like figure 2 As shown, according to a preferred embodiment of the present invention, the dye spin-coating device of a DVDR disc with a longitudinal central axis 9 includes: a substrate 10 arranged horizontally, a spin-coating bowl 1 fixed on the upper surface of the substrate 10; The inside of the spin-coating bowl 1 is provided with a guide post 11 along the central axis, and a spin-coating bowl tray 3 is horizontally provided with a predetermined height of the guide post 11 for placing discs to be processed; The outside of the spin-coating bowl 1 is horizontally provided with a dye mechanical arm 7, one end of the mechanical arm 7 is connected to the pillar 12 and can rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com