A patch-type electrowetting display module splicing screen and its drive control device

An electrowetting display, patch technology, applied in static indicators, optics, instruments, etc., can solve the problems of ink continuity damage, less types of high-voltage chips, and high rejection rate, to avoid uneven ink filling, The effect of solving driving difficulties and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

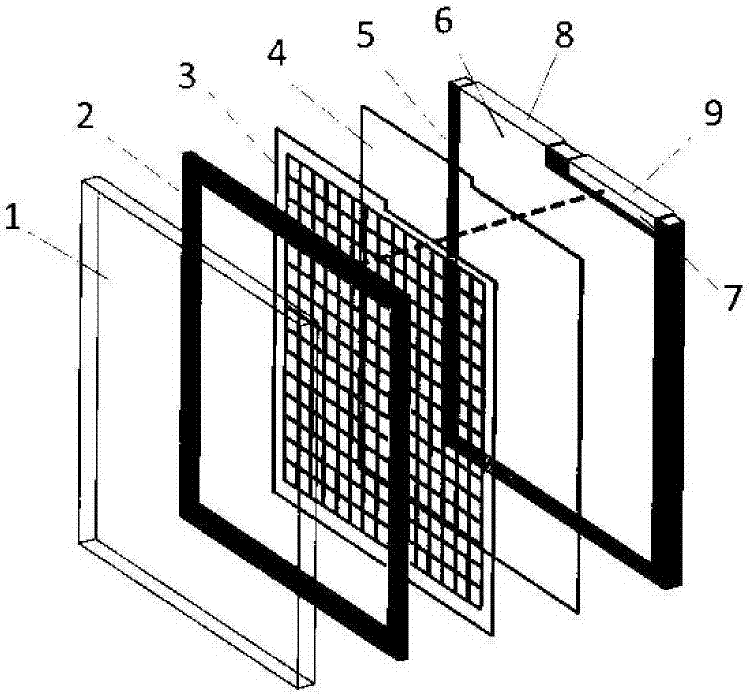

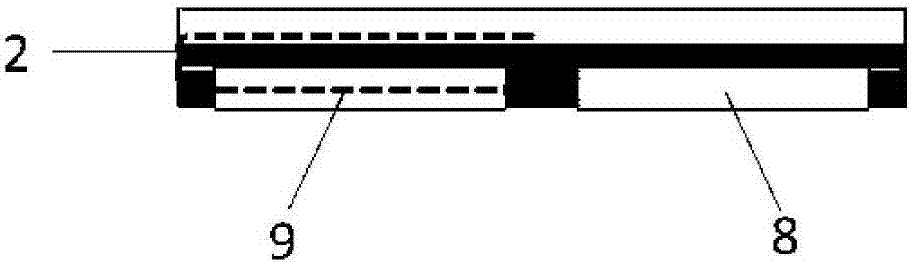

[0034] refer to figure 1 — Figure 8 , a patch-type electrowetting display module splicing screen of the present invention includes a backplane 15 and a plurality of splicing electrowetting display modules 14 arranged on the backplane 15 .

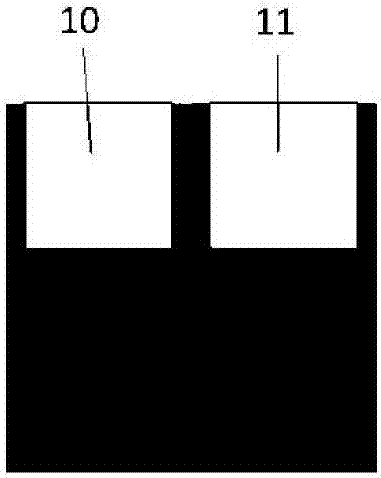

[0035] Each electrowetting display module 14 includes an upper conductive substrate 1, a conductive sealant frame 2, a pixel structure layer 3, a hydrophobic insulating layer 4, and a lower conductive substrate 5 arranged in sequence; the upper conductive substrate 1, conductive sealing frame 2, A sealed cavity is formed between the pixel structure layers 3, and the sealed cavity is filled with a conductive first fluid and a non-conductive second fluid, and the first fluid and the second fluid are in contact with each other and are immiscible; in this embodiment , the first fluid is an electrolyte solution, and the second ink. The grid surrounded by the pixel structure layer 3 is the display area.

[0036] The lower conductive substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com