Material injection gun head and refrigerator cabinet polyurethane material injection system with same

A technology of injection and injection port, which is applied in the field of polyurethane injection molding, can solve problems such as uneven filling of polyurethane, and achieve the effects of accelerating filling speed, improving production efficiency, and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

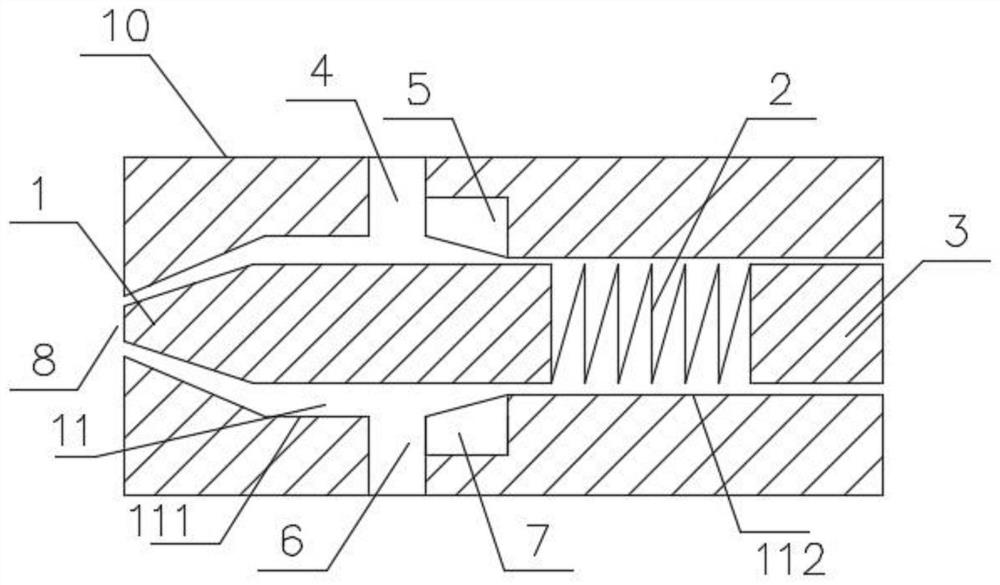

[0022] Embodiment 1, see figure 1 As shown, a filling gun head includes a gun head body 10, a cavity 11 is arranged in the gun head body 10 along its axial direction, and a discharge end of the cavity 11 is provided with a conical The material injection port 8 is equipped with a plug 1 at the injection port 8, and the end of the plug 1 is connected with a connecting rod 3 through a spring 2; the cavity 11 includes a first cylindrical cavity 111 with an inner diameter of R1 and a first cylindrical cavity with an inner diameter of R2 The second cylindrical cavity 112, the end of the second cylindrical cavity 112 communicates with the injection port 8; the connecting rod 3 and the spring 2 are located in the first cylindrical cavity 111, and one end of the connecting rod 3 runs through the first cylindrical cavity 111 and extend to the outside of the gun tip body 10, R1>R2; the gun tip body 10 is also provided with a material A inlet 4, a material A return port 5, a B material in...

Embodiment 2

[0024] Embodiment 2, an injection system based on the injection gun head of the above-mentioned embodiment 1:

[0025] It includes a program input module, an information processing module, an action module and an injection gun head; the action module connects the connecting rod 3 and drives the connecting rod 3 to expand and contract back and forth in the cavity 11; the information processing module is used to convert the program of the program input module into The electrical signal is sent to the action module.

[0026] Input and save the injection program of the Z box foaming molds through the program input module, and input the corresponding injection program for the box corresponding to each mold according to the model size characteristics; start the polyurethane injection action, when a waiting After the foamed empty box enters the corresponding mold, the elastic injection gun head is in place, and the injection starts according to the injection program corresponding to ...

Embodiment 3

[0027] Embodiment 3, the injection control method based on the injection system of the above-mentioned embodiment 2 includes:

[0028] Stp1. Input the injection volume and variable injection flow rate through the program input module;

[0029] Wherein, the variable injection flow rate is set as flow rate X1 g / s duration Y1 s, flow rate X2 g / s duration Y2s...flow rate Xng / s duration Yns, input n≥3;

[0030] Stp2. If the overall actual injection time T ≤ set the duration of each flow section ΣY, the injection will stop naturally when the injection time T is completed; if the overall injection time T > set the duration of each flow section ΣY, ΣY time is completed , continue to inject material according to the flow rate of the last stage until the injection amount is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com