Box-shaped truss type four-stand column deep water platform system with asymmetric soft cabin

A deep-water platform, asymmetric technology, applied in the direction of ships, floating buildings, etc., can solve the problems of reduced structural fatigue life and large joint fatigue stress, and achieve the effects of low construction difficulty, reduced joint stress, and reduced horizontal wave force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

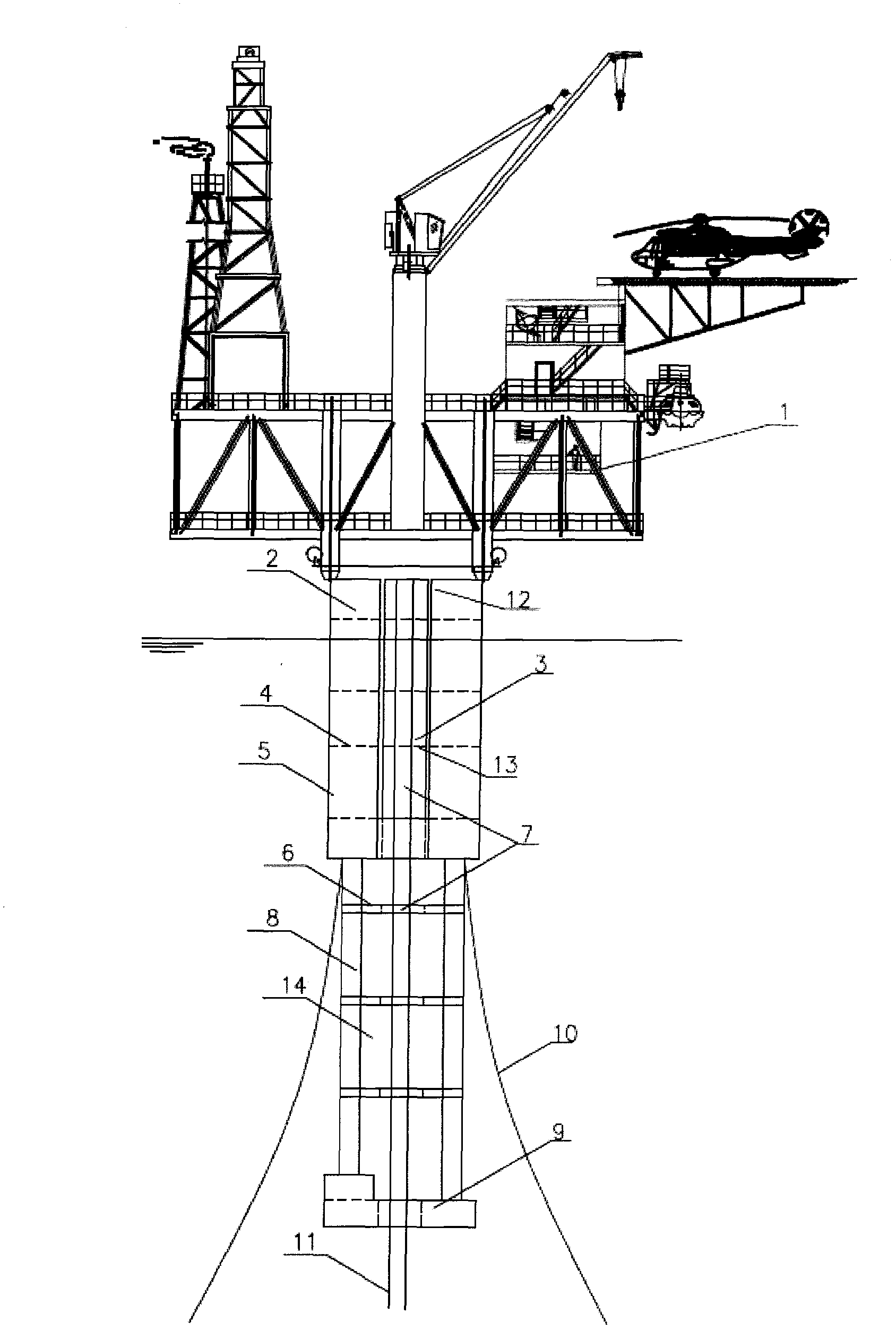

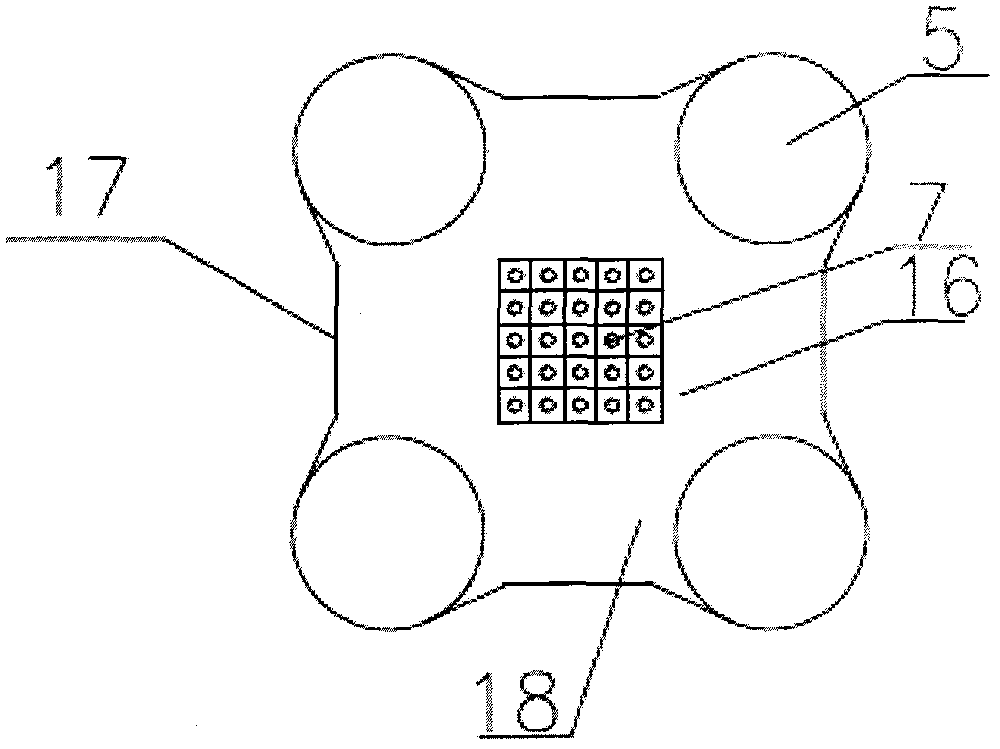

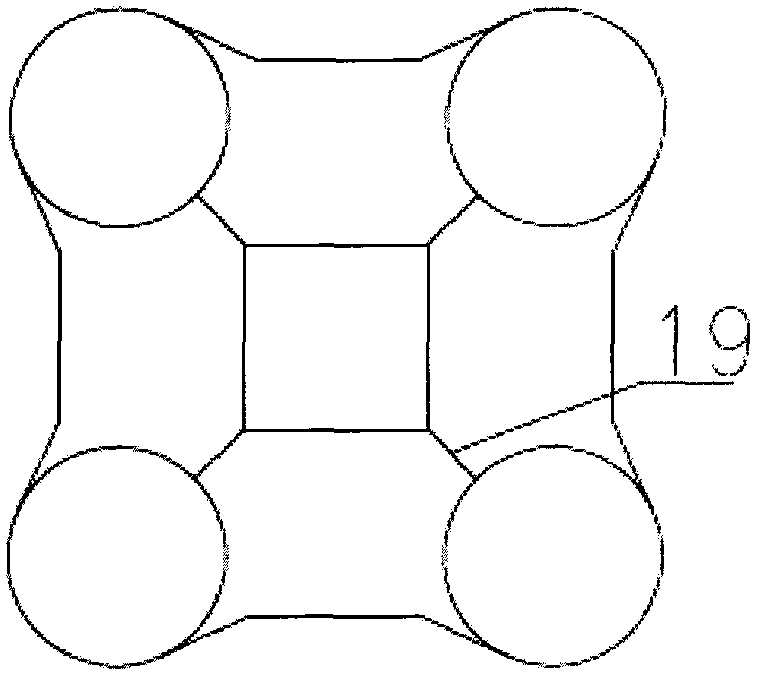

[0021] The overall structure of the present invention is as figure 1 As shown, it specifically includes: a top module 1, a hard cabin 2, a central well 7, a truss structure 8, a soft cabin 9, a mooring rope 10 and a TTR riser 11. It is characterized in that: the hard cabin 2 adopts the form of four columns, The upper part of the hard cabin 2 is connected to the top module 1 through the deck legs 12, and the hard cabin 2 is evenly distributed outside the central well 7, and connected to the central well 7 through the reinforced plate structure 19 and the horizontally connected hard cabin cabin 18, which mainly provides buoyancy for the platform The soft cabin 9 is located at the bottom of the platform, and adopts an asymmetrical cabin design. The ballast in the cabin is water or a solid with higher density, so that the center of buoyancy of the platform is higher than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com