Method and apparatus of improving recovery efficiency of shale gas through a blast mode

A shale gas and recovery factor technology, which is applied in earth-moving drilling, production fluids, wellbore/well components, etc. Effects of increasing range, increasing total surface area, increasing resolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

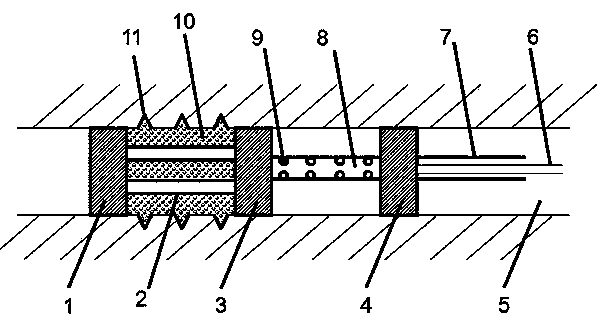

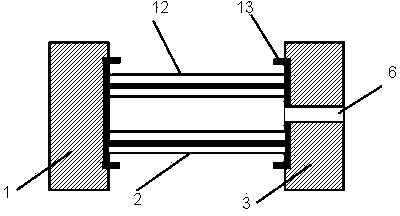

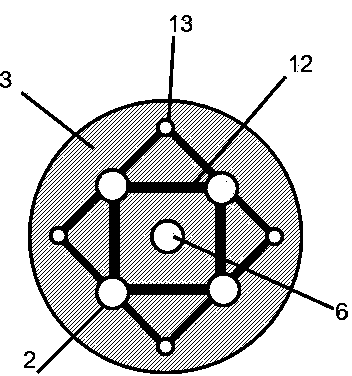

[0022] Such as figure 1 As shown, the device for increasing the recovery rate of shale gas by means of explosion disclosed in the present invention includes a drug injection detonation device and a gas delivery device, wherein the drug delivery detonation device includes: a lower isolation device 1, a high-strength connecting column 2, a middle isolation device Device 3, drug delivery tube 6, detonation circuit 12 and detonation device 13. The gas conveying device includes: middle isolating device 3 , upper isolating device 4 , oil and gas pipe 7 , and perforated air intake pipe 8 .

[0023] Such as figure 1 , 2 , 3, the device for increasing the recovery rate of shale gas by means of explosion in this embodiment is set in the open hole 5 of the shale gas well. The lower isolating device 1, the middle isolating device 3 and the upper isolating device 4 in the drug delivery detonating device and the gas conveying device are columnar structures with the same cross-sectional s...

Embodiment 2

[0028] The structure and usage method of this embodiment are basically the same as those of the device for increasing shale gas recovery by means of explosion defined in Embodiment 1. The difference is that the device for increasing the recovery of shale gas by means of explosion in this embodiment does not include the drug delivery tube 6, and the middle isolation device 3 is not provided with a through hole, but a blind hole can be provided on the upper surface so that The positioning of the hole-shaped air intake pipe 8; the explosive device for infusion is a closed structure, that is, a side wall structure is set between the lower isolation device 1 and the middle isolation device 3, and the space between the lower isolation device 1 and the middle isolation device 3 is used for loading explosives. space is closed. And when making the device for increasing the recovery rate of shale gas by means of explosion, explosives are put into the explosive detonation device in advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com