Nano Al2O3 reinforced 3D printing aluminum-based composite material and preparation method

An aluminum-based composite material and 3D printing technology, which is applied in the field of metal 3D printing, can solve the problems that the structure and performance of aluminum alloy parts cannot meet the application requirements, and achieve the effect of realizing the degree of densification, shortening the production cycle and high cooling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a nano-Al 2 o 3 A preparation method for enhancing 3D printing aluminum-based composite materials, comprising the following steps:

[0025] Step 1, homogeneous mixing of powder

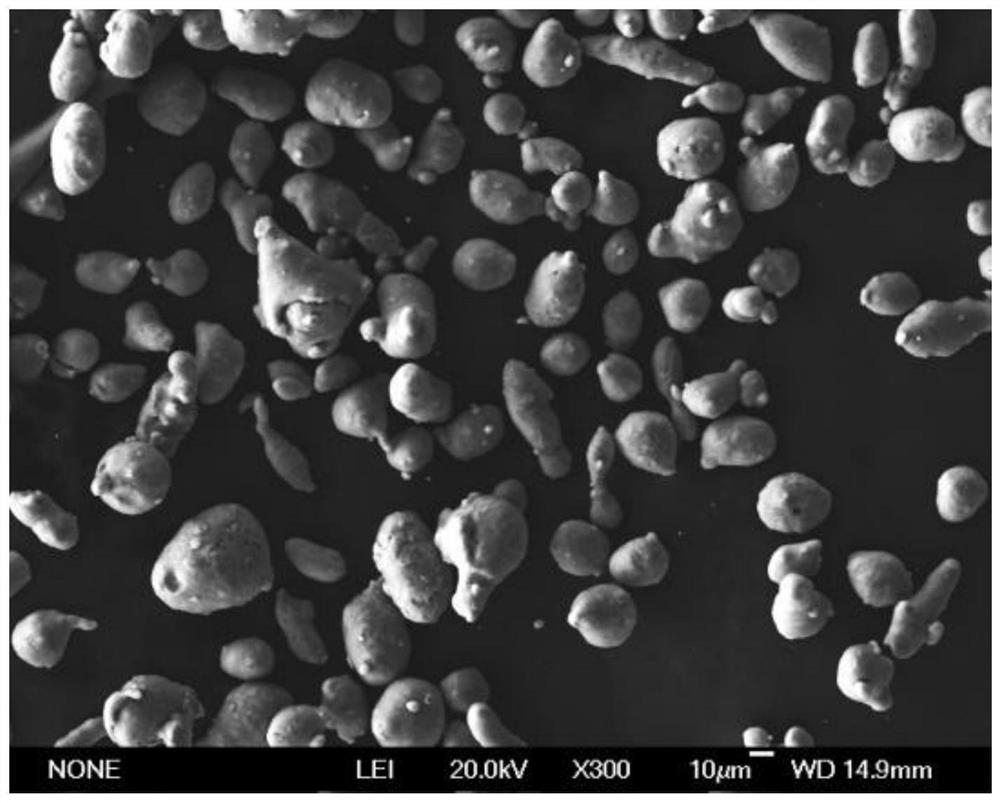

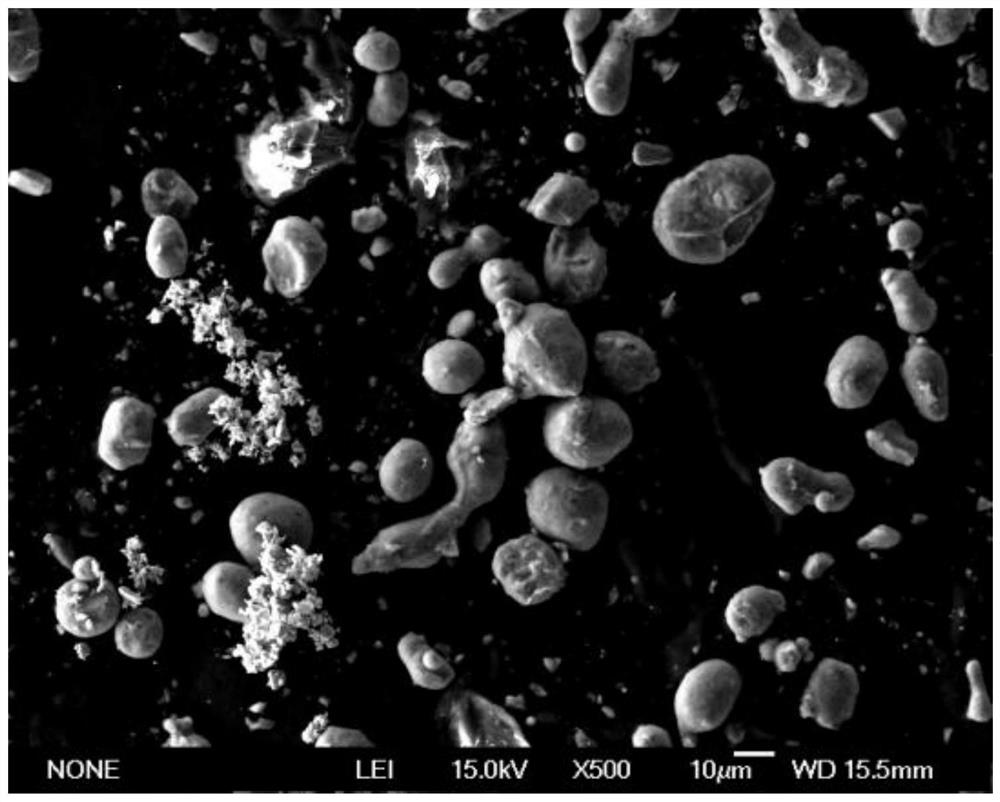

[0026] Nano Al 2 o 3 Mix with Al-based spherical powder according to a certain ratio through a ball mill to obtain a composite powder for printing;

[0027] In step 1, the composite powder is composed of the following raw materials according to mass percentage: 0.1wt% to 30wt% nano-scale Al 2 o 3 and 70wt% to 99.9wt% of Al-based spherical powder, the sum of the mass percentages of the above components is 100%; ball milling is carried out in a liquid environment containing alcohol, the speed of the ball mill is set at 50 to 400rpm, and the intermittent ball milling method is adopted. The actual ball milling The time is 0.5 ~ 20h.

[0028] Step 2, roast the powder and sieve

[0029] After placing the composite powder obtained in step 1 in an oven for heat preservati...

Embodiment 1

[0036] Step 1, homogeneous mixing of powder

[0037] Nano Al 2 o 3 and Al-based spherical powder according to a certain ratio, mixed by a ball mill to obtain a composite powder for printing; the composite powder is 2.25wt% nano-scale Al 2 o 3 and 97.75wt% Al-based spherical powder, the sum of the mass percentages of the above components is 100%; the ball milling is carried out in a liquid environment containing alcohol, the speed of the ball mill is set at 150rpm, and the intermittent ball milling method is adopted. The actual ball milling time is 4h;

[0038] Step 2, roast the powder and sieve

[0039] The composite powder obtained in step 1 was placed in an oven at 80° C. for 4 hours, and then sieved with a 100-mesh sieve.

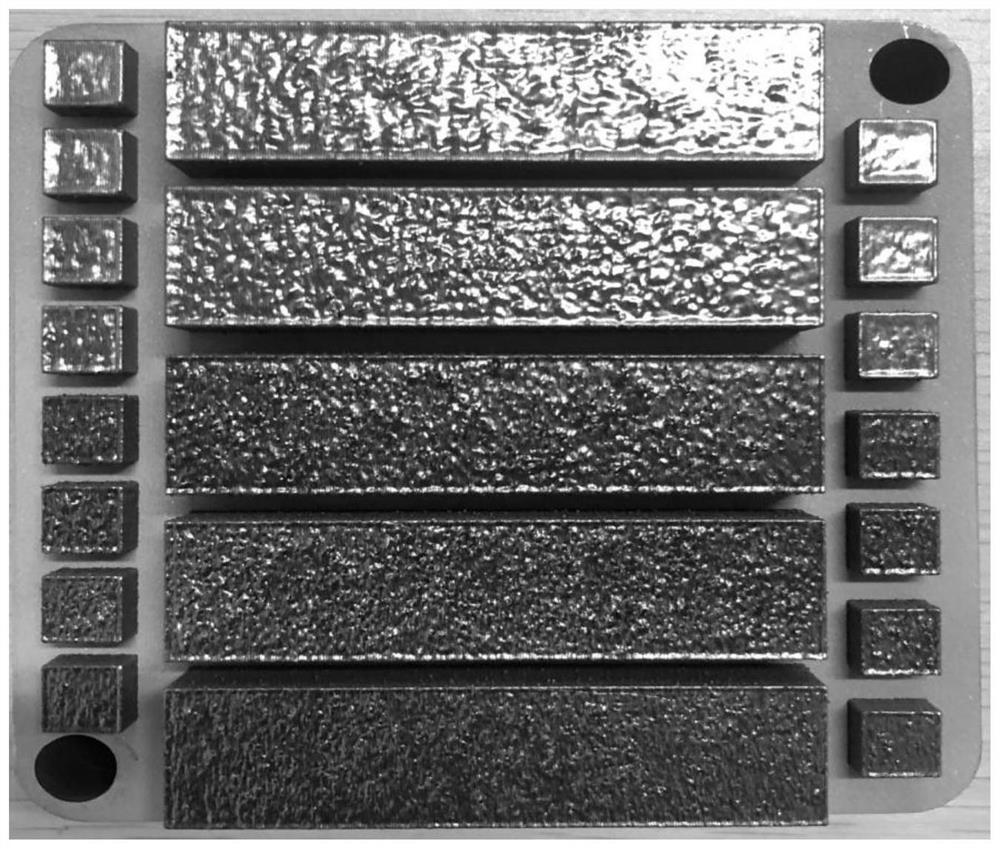

[0040] Step 3, print shape

[0041] Add the mixed powder to the powder feeding system of the selective laser melting forming equipment, and then spread the powder evenly through the powder spreading roller. , preheating, melting and forming process, ...

Embodiment 2

[0044] Step 1, homogeneous mixing of powder

[0045] Nano Al 2 o 3 and Al-based spherical powder according to a certain ratio, mixed by a ball mill to obtain a composite powder for printing; the composite powder is 0.1wt% nano-scale Al 2 o 3 and 99.9wt% Al-based spherical powder, the sum of the mass percentages of the above components is 100%; the ball milling is carried out in a liquid environment containing alcohol, the speed of the ball mill is set at 50rpm, and the intermittent ball milling method is adopted. The actual ball milling time is 20h;

[0046] Step 2, roast the powder and sieve

[0047] The composite powder obtained in step 1 was placed in an oven at 50° C. for 40 hours, and then sieved with a 600-mesh sieve.

[0048] Step 3, print shape

[0049] Add the mixed powder to the powder feeding system of the selective laser melting forming equipment, and then spread the powder evenly through the powder spreading roller. , preheating, melting and forming process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com