Molded paper roll die

A paper roll and mold technology, which is applied in the field of molded paper roll molds, can solve the problems of forest resource destruction and environmental protection disadvantages, and achieve the effect of reducing damage and being beneficial to environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

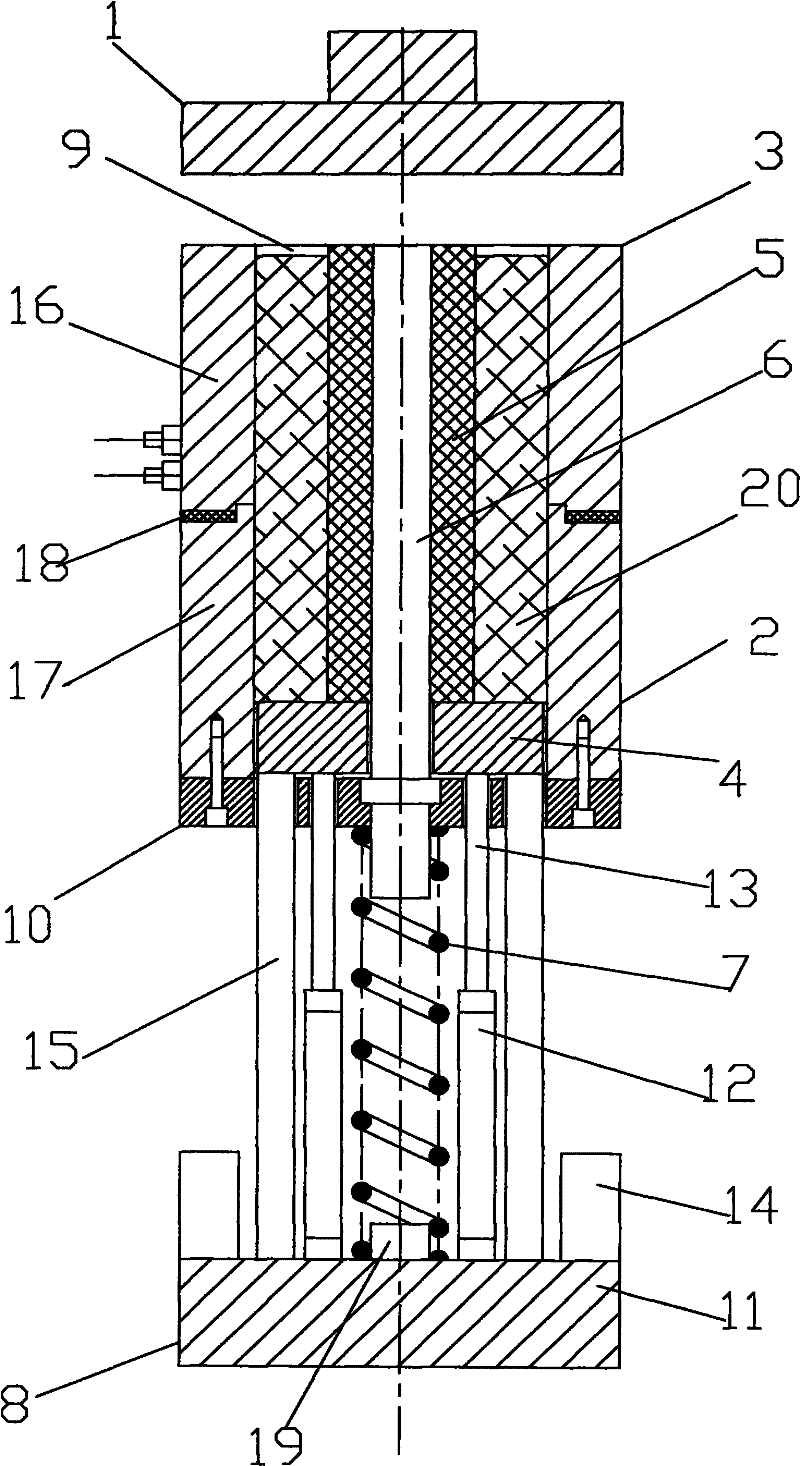

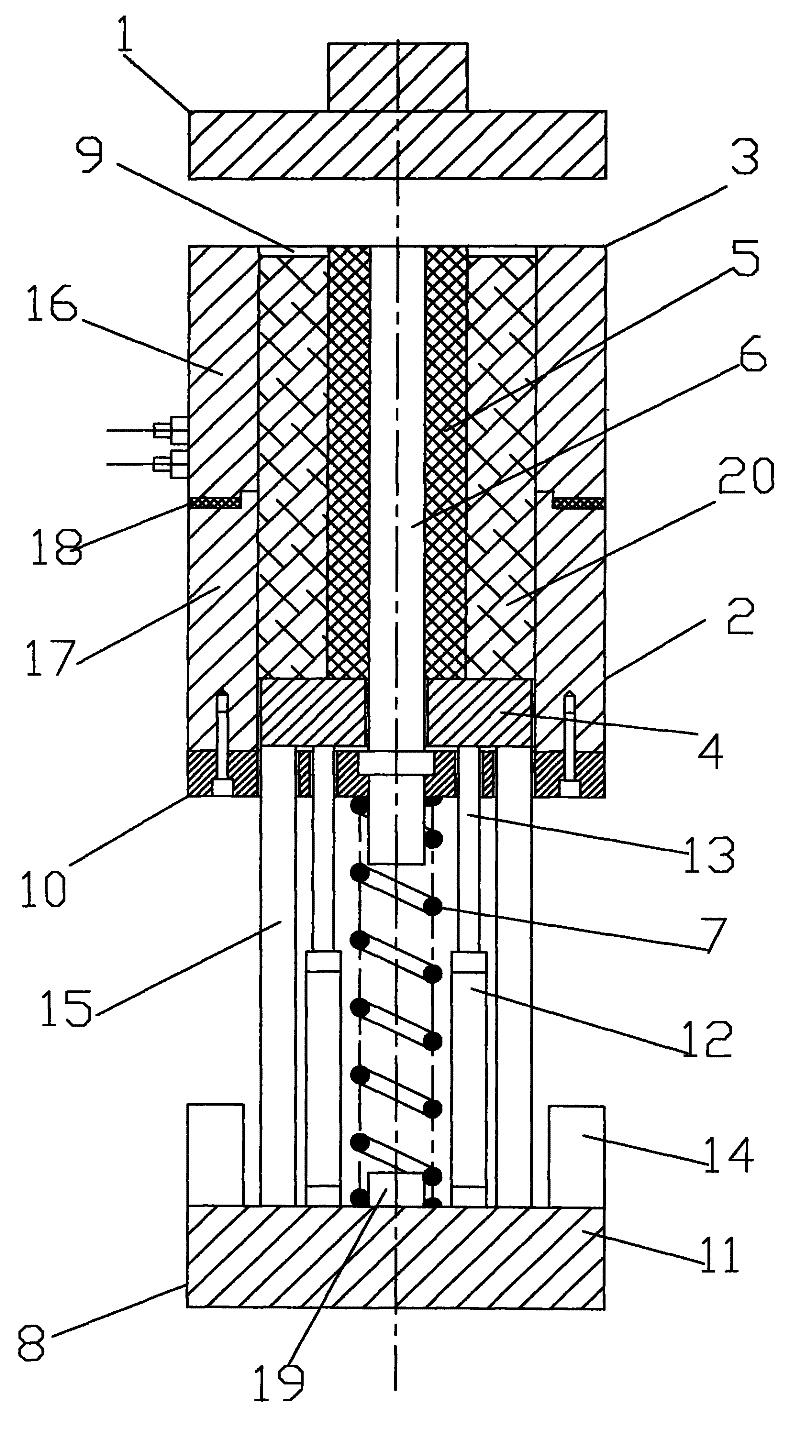

[0008] Below in conjunction with accompanying drawing, the present invention is further described:

[0009] figure 1 The schematic diagram of the mold paper reel mold structure is shown. The mold paper reel mold includes an upper mold 1 and a lower mold 2. The lower mold 2 consists of a hot pressing mold frame 3, a release plate 4, an expansion member 5, a mold core 6, and a spring 7. The mold base 8 and the demoulding pushing element 12 are formed. The stripping plate 4 is connected to the mold base 8. The stripping plate 4 is located in the hot pressing mold frame 3. The stripping plate 4 is connected with the hot pressing mold frame 3. The mold core 6 is connected to the hot pressing mold frame 3. The stripping plate 4 is connected in a moving fit, and the mold core 6 is fixedly connected with the hot-pressing mold frame 3, so that the mold core 6 and the hot-pressing mold frame 3 can be lowered with the pressing of the upper mold 1. The mold core 6 is located in the middle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap