Antistatic composite material, electronic device shell and electronic device

A composite material and electronic equipment technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, etc., can solve the problems of not well balanced material toughness and rigidity, unsuitable shell of communication equipment, etc., to achieve good anti-static effect, good mechanical properties, good antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

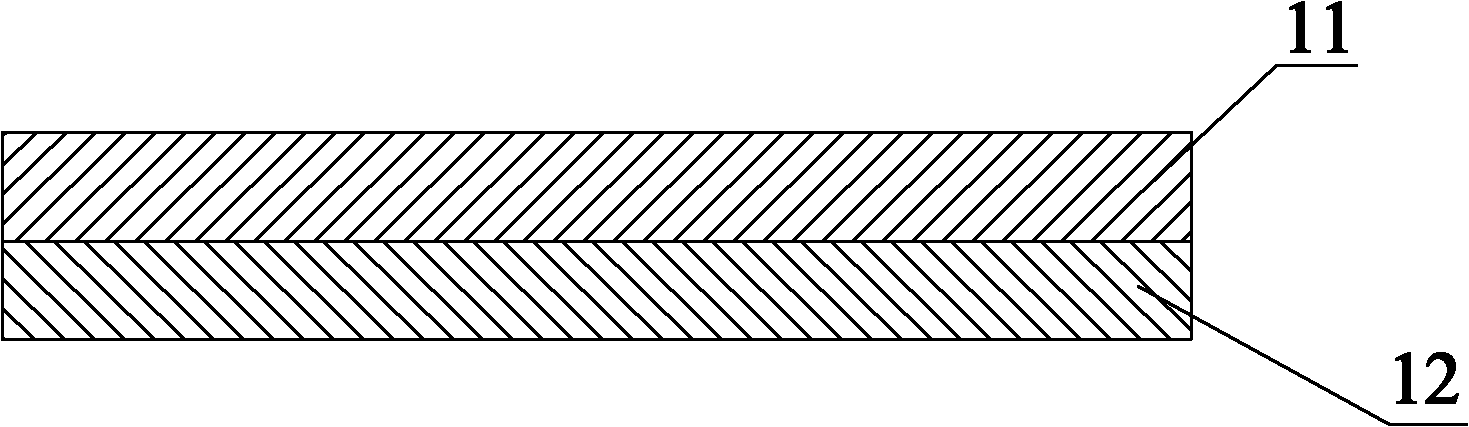

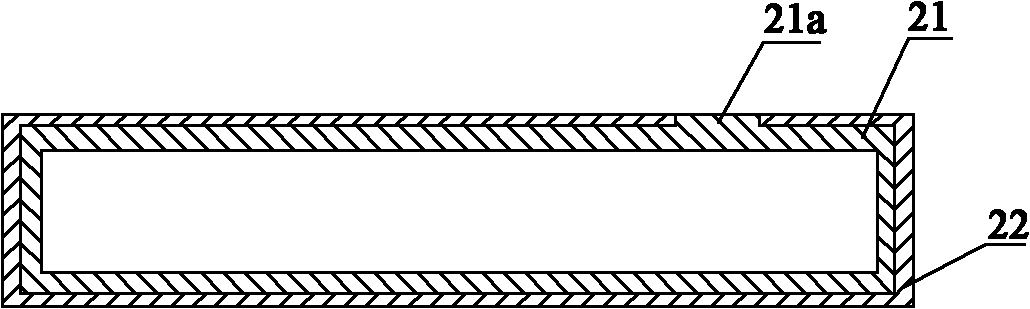

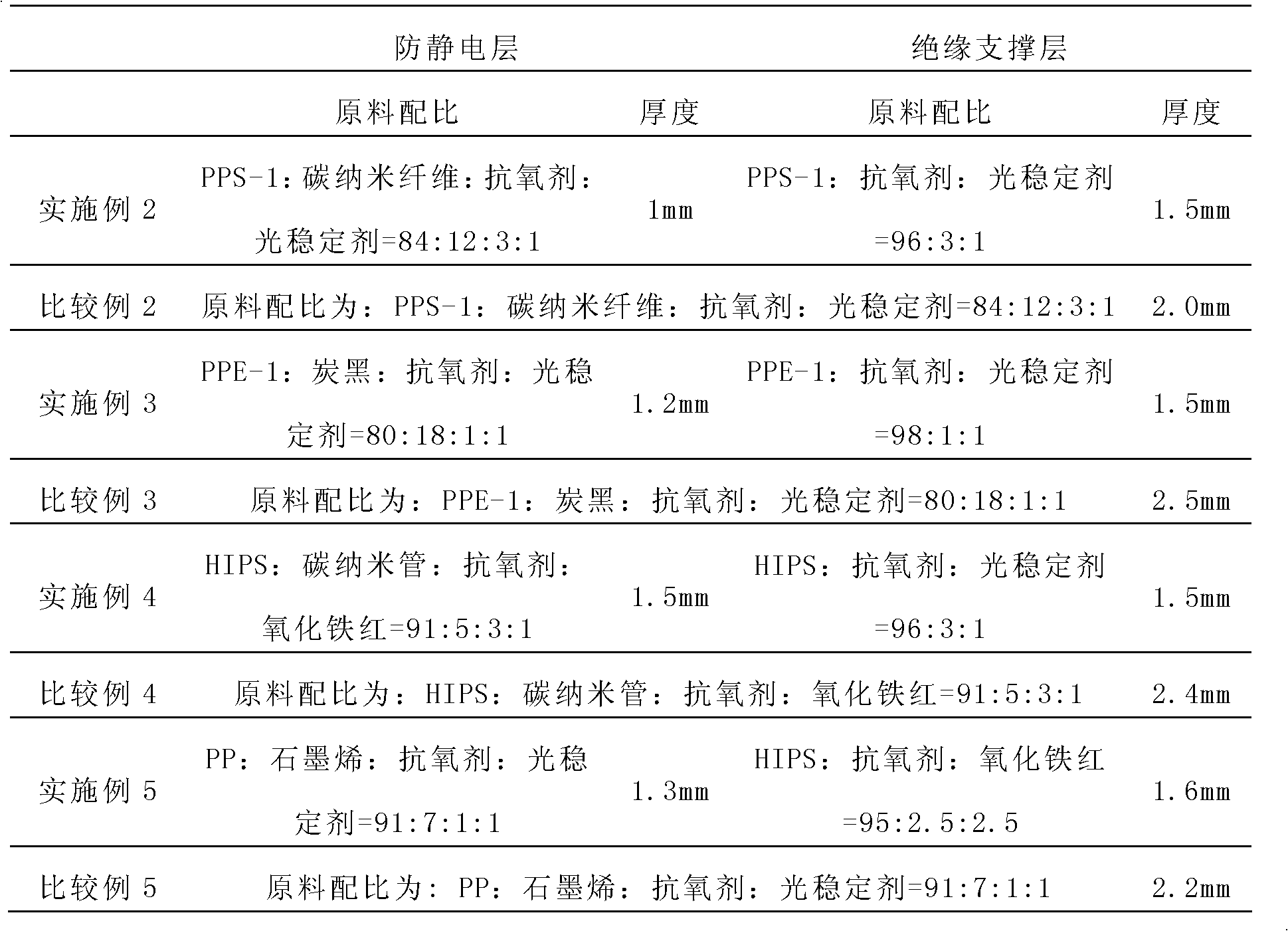

[0061] Antistatic layer components:

[0062] 81% polyethylene, 16% carbon fiber, 2% antioxidant, 1% light stabilizer;

[0063] Support layer components:

[0064] 97% polyethylene, 2% antioxidant, 1% light stabilizer;

[0065] The above-mentioned antistatic layer component and support layer component were subjected to double injection molding to obtain a composite material, and an antistatic layer with a thickness of 1.5 mm and a support layer with a thickness of 1.6 mm were obtained. The mechanical and electrical properties were measured and listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com