Laminated medium aligning mechanism and processing unit provided with same

A sheet medium and medium conveying technology, applied in thin material handling, transportation and packaging, object supply, etc., can solve problems such as inability to ensure reliable alignment at the same time, and achieve reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

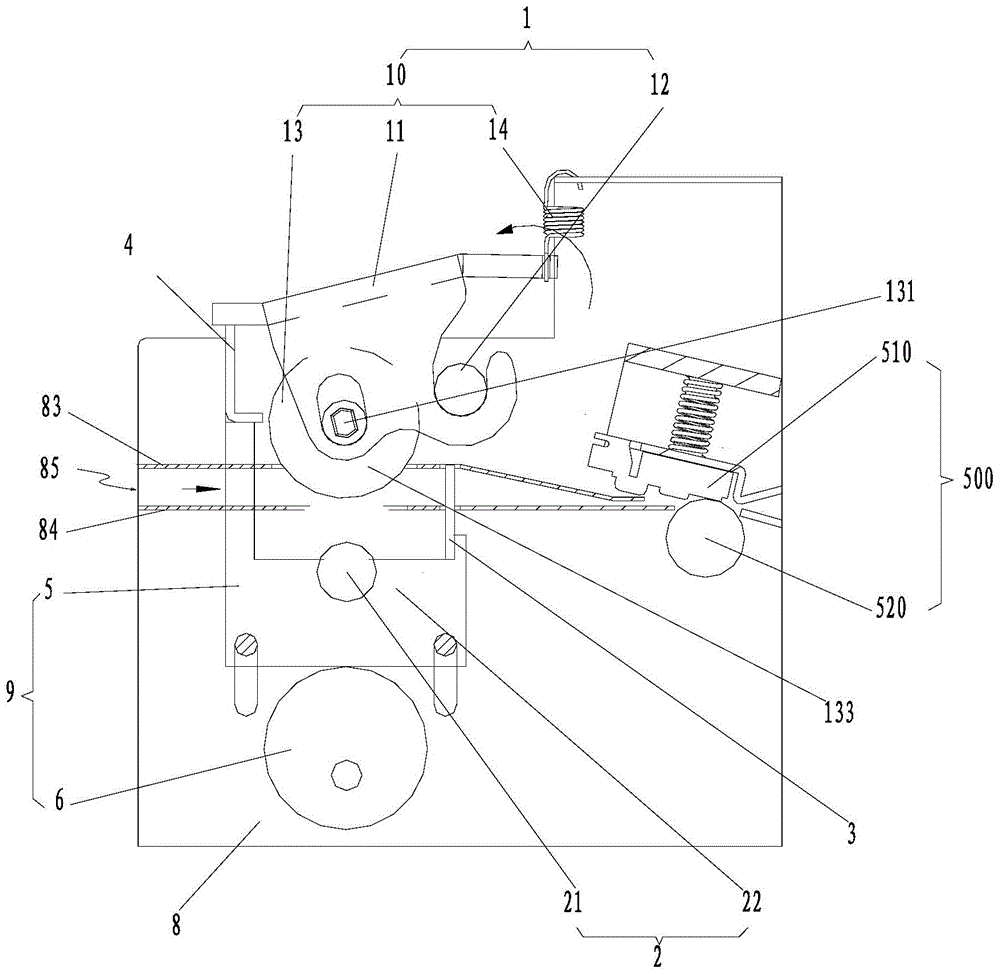

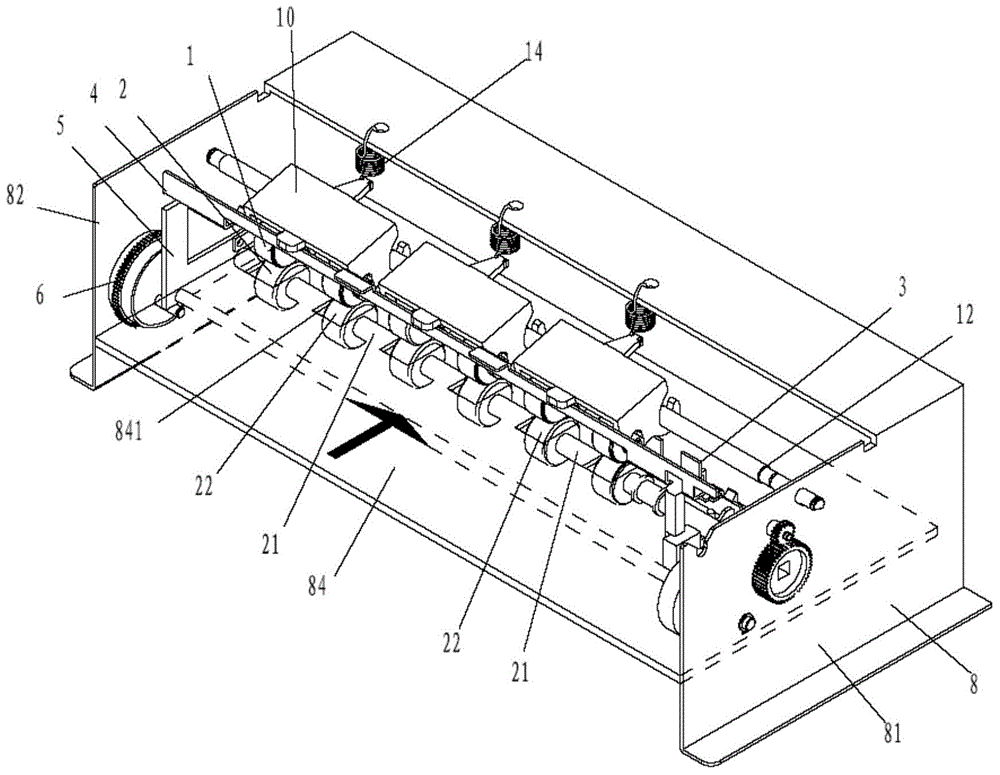

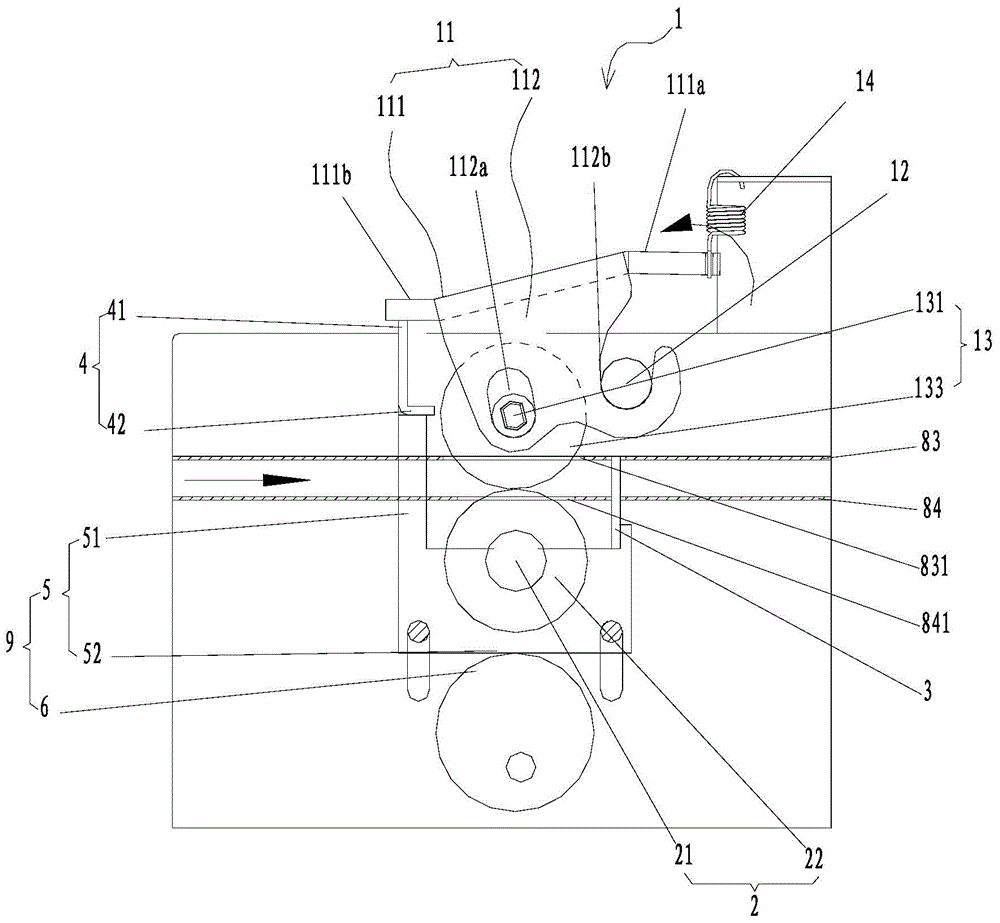

[0025] figure 1 It is a longitudinal sectional view of a sheet medium processing device using the sheet medium alignment mechanism of the present invention, figure 2 It is an isometric view of the first embodiment of the sheet medium alignment mechanism according to the present invention. Such as figure 1 and figure 2 As shown, the sheet medium processing device includes a frame 8 , an alignment mechanism and a medium processing mechanism 500 .

[0026] The frame 8 includes a left side wall 81, a right side wall 82, a first channel plate 83, and a second channel plate 84, wherein the left side wall 81 and the right side wall 82 are relatively parallel, and the first channel plate 83 and the second channel plate The plate 84 is vertically suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com