Warm core floor, manufacturing method thereof and conductive heating plate for warm core floor

A heating plate and floor technology, applied in the field of warm core floor, can solve the problems of low heat transfer efficiency, difficult installation and maintenance, complicated installation process, etc., and achieve the effect of good temperature control performance and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

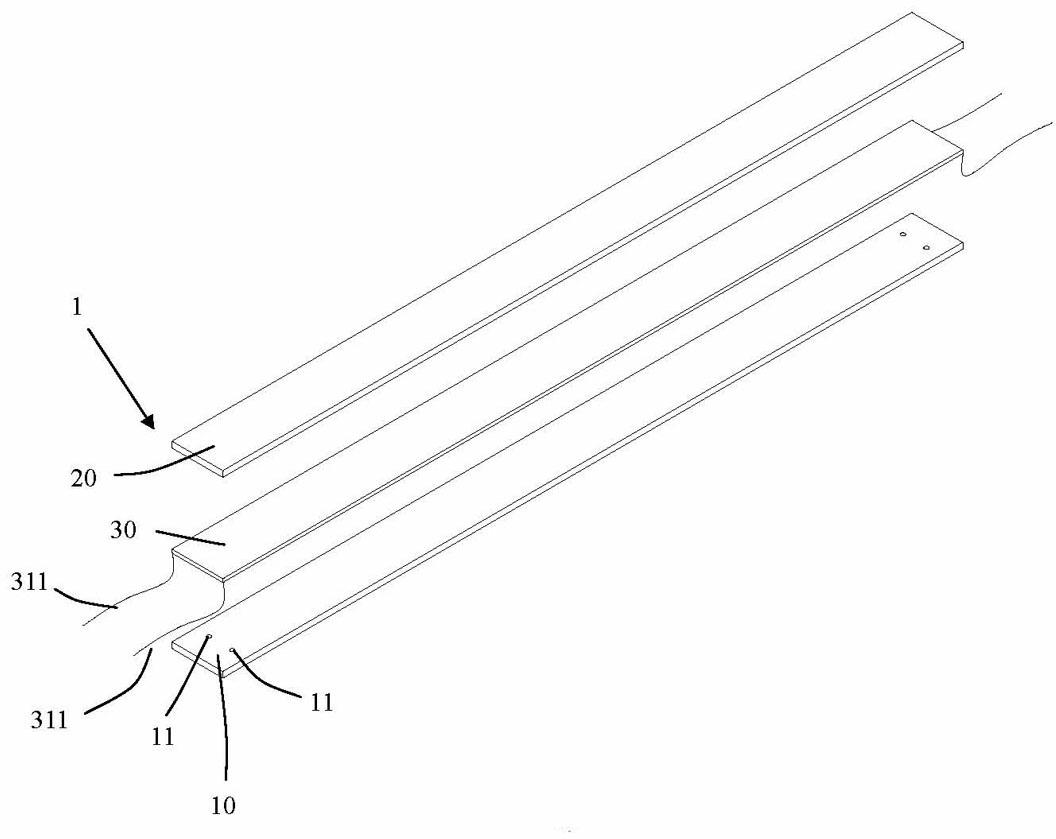

[0026] refer to figure 1 As shown, the warm core floor 1 of the present invention is mainly composed of a lower plate 10, an upper plate 20 and a conductive heating plate 30. The conductive heating plate 30 is sandwiched between the lower plate 10 and the upper plate 20, and the lower plate 10 and the upper plate 20 mutual pressing; wherein:

[0027] The lower plate 10 and the upper plate 20 can be made of composite board or solid wood, and a lead hole 11 is provided at the end of the lower plate 10 for the lead wire of the conductive heating plate 30 to be connected to an external power source.

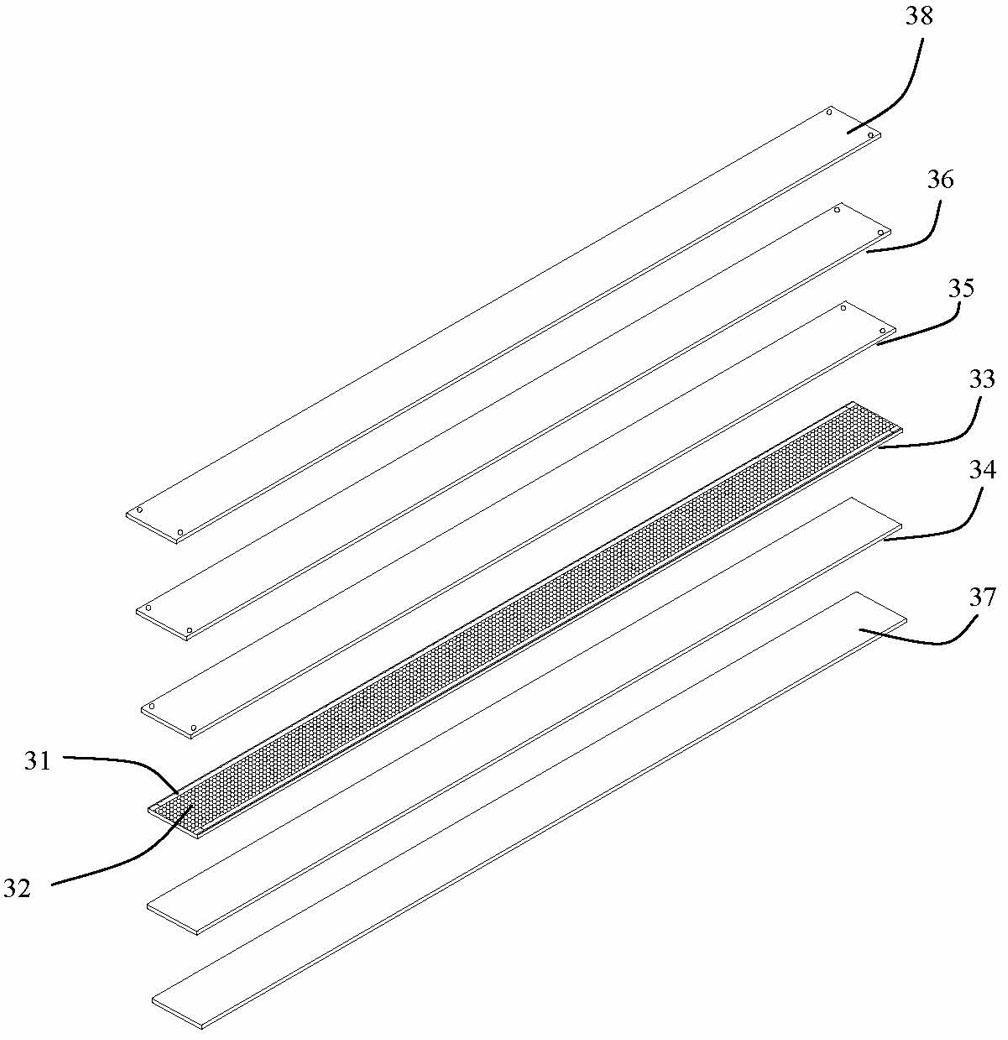

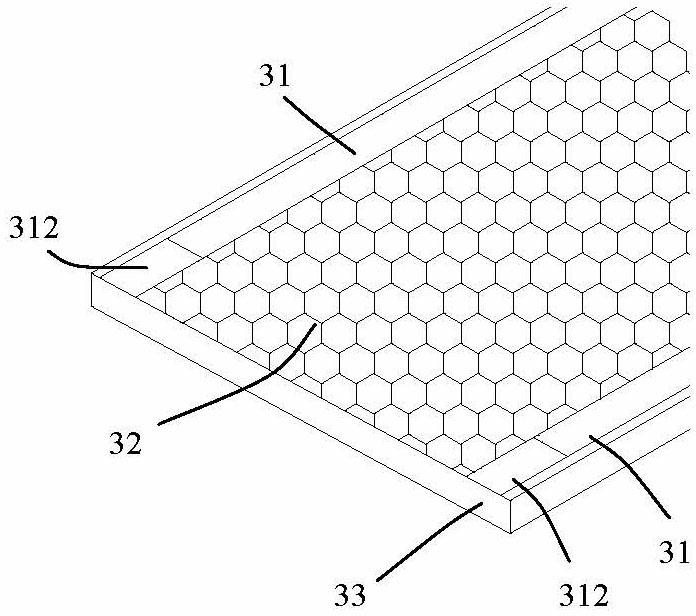

[0028] Cooperate figure 2 As shown, the shape of the conductive heating plate 30 is similar to the above-mentioned lower plate 10 and upper plate 20, but its area is slightly smaller than that of the lower plate 10 and the upper plate 20 so that it can be better pressed between the lower plate 10 and the upper plate 20. Between them, it mainly consists of upper and lower substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com