Polycrystalline diamond composite sheet

A polycrystalline diamond and composite sheet technology, which is used in metal layered products, drilling equipment, earth-moving drilling, etc. Improve wear resistance and impact toughness, reduce the effect of interface stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

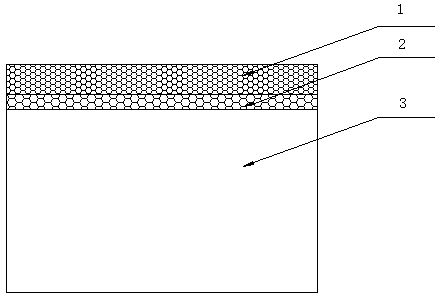

[0058] like figure 1 As shown, the polycrystalline diamond compact includes the following three components: a polycrystalline diamond layer 1 , a transition layer 2 , and a cemented carbide layer 3 . The composite interface between the transition layer 2 and the cemented carbide layer 3 is a plane or a concave-convex surface. For the transition layer 2, diamond particles, tungsten carbide particles and a binder are mixed, or an appropriate amount of titanium carbonitride particles is added. According to the mass ratio, select 60-70% of diamond particles with a particle size of 5-40um; 20-30% of tungsten carbide particles with a particle size of 1-10um; 5-15% of a binder with a particle size of 5-10um; Titanium carbonitride 0~10%. The thickness ratio of the transition layer 2 to the polycrystalline diamond layer 1 is 0.5-1. Laboratory tests have proved that compared with the existing polycrystalline diamond composite sheet of the same specification, the performance test of t...

Embodiment 2

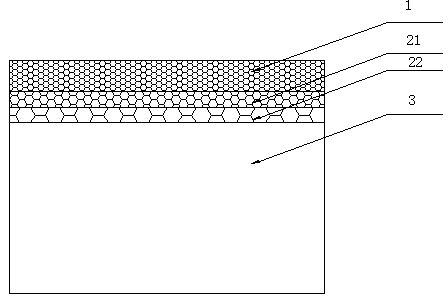

[0060] like figure 2 As shown, the difference from Example 1 is that the transition layer is composed of a first transition layer 21 and a second transition layer 22, the first transition layer 21 is near the polycrystalline diamond layer 1, and the transition layer 2 is near the cemented carbide layer 3. The second transition layer 22 . The first transition layer 21 and the second transition layer 22 are composed of two layers of diamond grains, tungsten carbide grains and binders mixed with different proportions, or a small amount of titanium carbonitride grains are appropriately added. The composition of the first transition layer 21 composited with the polycrystalline diamond layer 1 is: 70-80% of diamond particles with a particle size of 5-40um; 10-20% of tungsten carbide particles with a particle size of 1-10um; a combination of Agent 5~15%; or add 0~10% of titanium carbonitride particles with a particle size of 1~5um. The composition of the second transition layer 22...

Embodiment 3

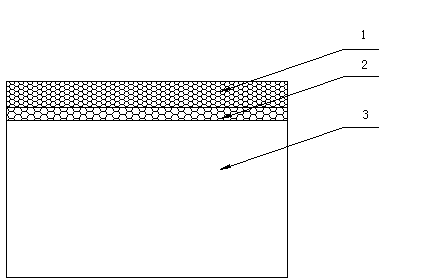

[0062] like image 3 As shown, the transition layer 2 in the polycrystalline diamond composite sheet is composed of diamond particles and a binder, wherein the polycrystalline diamond layer 1 selects diamond particles with a particle size of 5-20um; the transition layer 2 selects diamond particles with a particle size of 10-40um, and then according to Need to add the right amount of binder. The particle size of the binder in the transition layer 2 is 5-10um, and the addition ratio is 0-20%. The thickness ratio of the polycrystalline diamond layer 1 and the transition layer 2 is 0.5-1. The finer diamond particles of the polycrystalline diamond layer 1 can be selected to achieve the purpose of improving wear resistance, while the transition layer 2 selects thicker diamond particles to ensure higher impact toughness, and the polycrystalline diamond layer provides a higher impact resistance. good support. Laboratory tests show that compared with conventional and existing polycr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com