A kind of preparation method of zinc oxide particle reinforced aluminum matrix composite material

A zinc oxide particle-reinforced aluminum-based technology, which is applied in metal rolling and other directions, can solve the problems affecting the mechanical and electrical properties of metal-based composite materials, the volume fraction of reinforcements, and the sample is prone to pores, etc., and achieves simple operation and low cost. The effect of low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

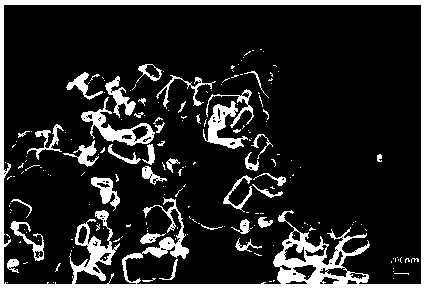

[0027] Example 1: 2.5vol.% nano-zinc oxide is sandwiched between pure aluminum that has been completely annealed, deoxidized, and degreased, and then continuously accumulated for 4, 8, and 12 passes at room temperature without lubrication rolling. In this embodiment, the aluminum content of the pure aluminum plate is 99.99%, and the size is: 100×20×0.25mm; the particle size of zinc oxide is 248nm. Adopt industrial rolling mill, rolling speed is 187mm / min. During each rolling pass, the reduction in the thickness direction of the sample is 50%. Perform surface treatment such as deoxidation and degreasing on the fully annealed pure aluminum sheet. After the weighed nano-ZnO particles are ultrasonically oscillated in acetone, they are evenly coated on the surface of the treated aluminum sheet. After the acetone volatilizes, the Multiple layers of aluminum sheets were stacked together and the two ends of the sample were fixed with glue, and rolled at room temperature. After one ...

Embodiment 2

[0033] Embodiment 2: The nano zinc oxide of 0.5vol.%, 2.5vol.% and 5.0vol.% is respectively clamped in the middle of pure aluminum through complete annealing and deoxidation film, degreasing treatment, then under the condition of no lubrication at room temperature It performs cumulative rolling 8 times continuously.

[0034] In this embodiment, the aluminum content of the pure aluminum plate is 99.99%, and the size is: 100×20×0.25mm; the particle size of zinc oxide is 248nm. Adopt industrial rolling mill, rolling speed is 187mm / min. During each rolling pass, the reduction in the thickness direction of the sample is 50%. After 8 passes of rolling, spark plasma sintering was carried out on the rolled sample. The sintering temperature used was 500°C, the sintering holding time was 5 minutes, and the sintering pressure was 80MPa. During the sintering process, the sample was protected by argon to prevent its oxidation.

[0035] Figure 5 It is a scanning electron microscope (SE...

Embodiment 3

[0039] Example 3: 5.0vol.% nano zinc oxide is sandwiched between pure aluminum that has been completely annealed, deoxidized and degreased, and then it is continuously rolled for 8 passes at room temperature without lubrication.

[0040] In this embodiment, the aluminum content of the pure aluminum plate is 99.99%, and the size is: 100×20×0.25mm; the particle size of zinc oxide is 248nm. Adopt industrial rolling mill, rolling speed is 187mm / min. During each rolling pass, the reduction in the thickness direction of the sample is 50%. After rolling for 12 passes, discharge plasma sintering was carried out on the rolled samples. The sintering temperature used was 500°C, the sintering holding time was 5 minutes, and the sintering pressure was 80MPa. During the sintering process, the samples were protected by argon to prevent their oxidation.

[0041] Figure 7 It is a scanning electron microscope (SEM) photo of the longitudinal section of the ZnO-reinforced aluminum matrix comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com