Patents

Literature

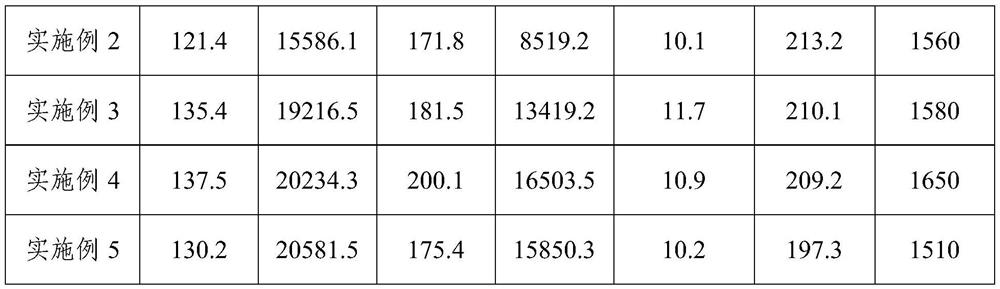

30results about How to "Improve interface integration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite as well as preparation method and application thereof

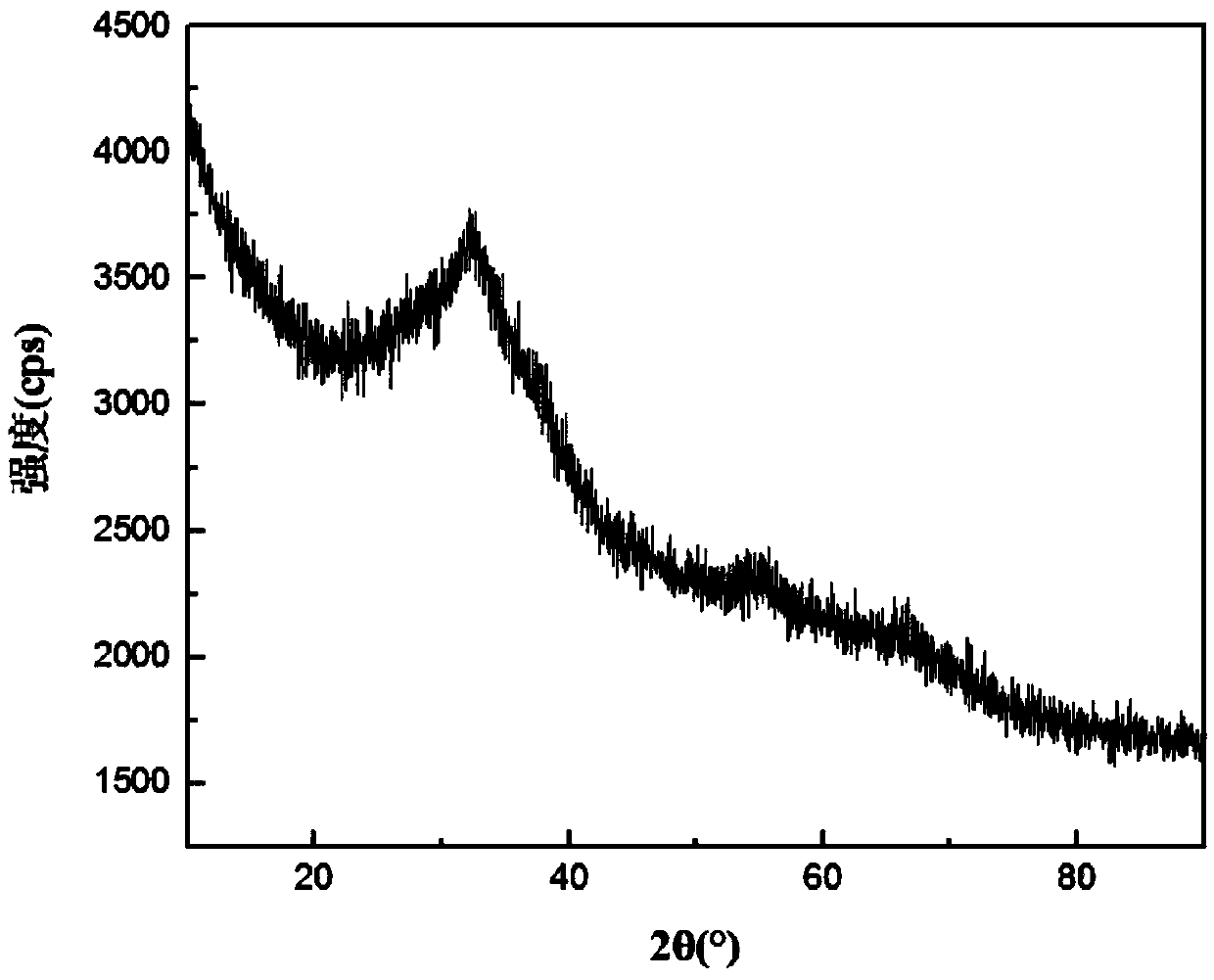

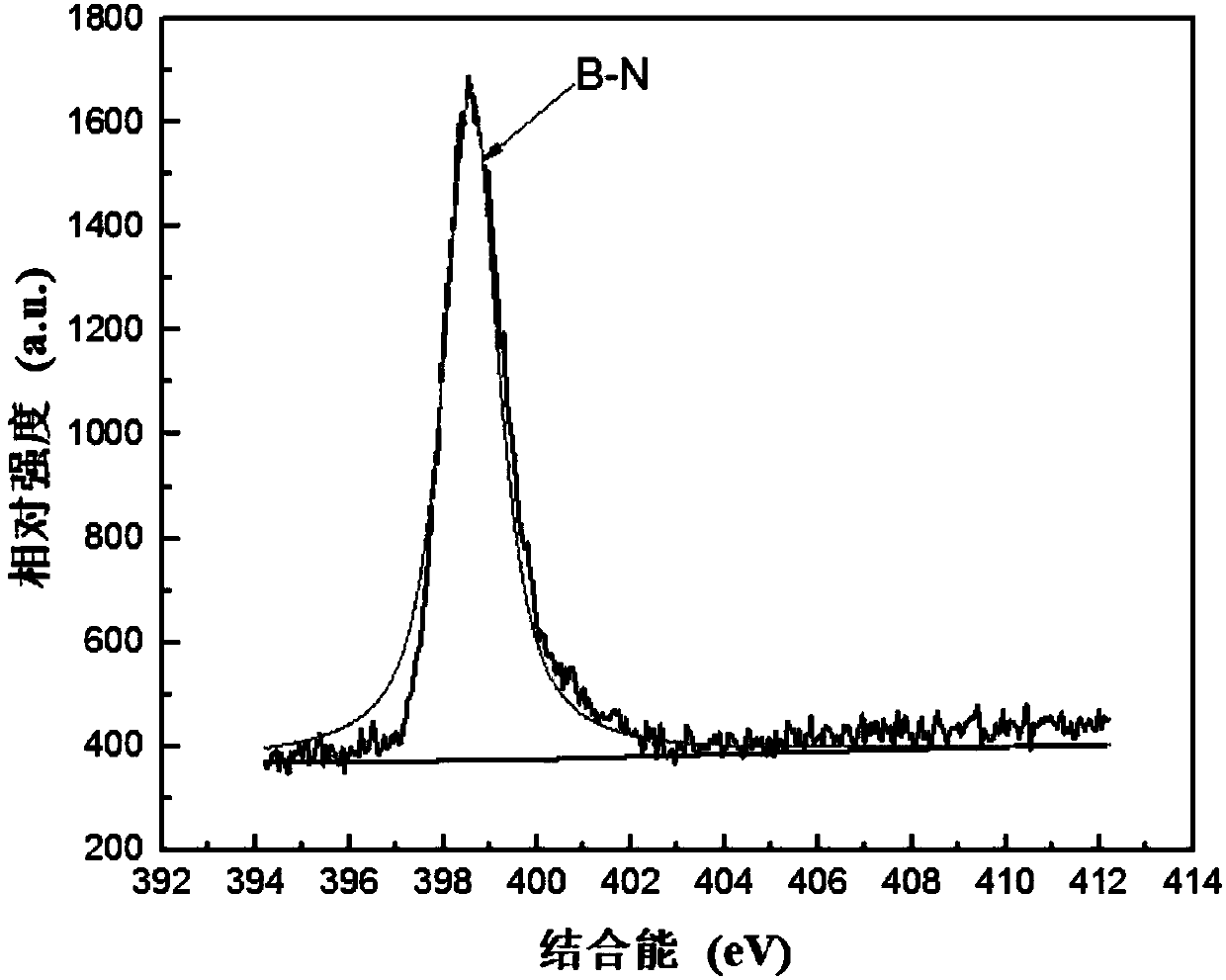

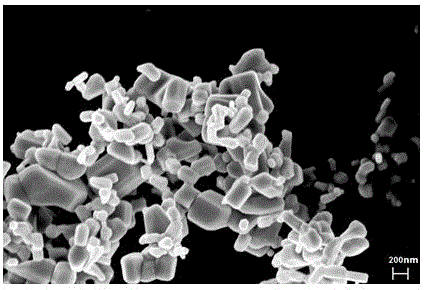

The invention discloses an ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite as well as a preparation method and an application thereof. The preparation method of the ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite comprises the following steps: S1, preparing Si-B-C-N-Zr powder; S2, performing surface modification treatment on fiber to obtain modifiedfiber; S3, mixing the modified fiber with the Si-B-C-N-Zr powder to obtain composite powder; S4, performing hot pressing and sintering on the composite powder to prepare the ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite. The prepared ablative-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite has good microstructure and higher fracture toughness, mechanical property and ablative resistance, used raw materials are widely sourced and low in price, the preparation process is simple and mature, the preparation period is short, all the steps can be realized with existing technologies and equipment, and the composite is suitable for industrial production.

Owner:HARBIN INST OF TECH

In-situ fiber-forming strengthened degradable medical elastic composite material and preparation method thereof

ActiveCN101623516AHigh tensile strengthAppropriate compatibilityCatheterProsthesisPoly-L-lactideFiber

The invention discloses an in-situ fiber-forming strengthened degradable medical elastic composite material and a preparation method thereof. The composite material is prepared by premixing polyglycolic acid or poly-(L-lactic acid) and poly-(L-lactide-tao-caprolactone) by a weight ratio of 20:80 to 5:95 in an inert gas atmosphere; extruding the mixture in a plastic extruder with a screw rotation speed of 10-80 r / min; hauling the extruded mixture by a hauling machine at a hauling speed of 1-30 m / min; controlling a die diameter / a spline diameter to be 1-6; and quenching with water in a hauling process. The composite material can be fully biologically degraded, has obviously improved tensile strength, enables fused mass to have little abrasion on the inner wall of an equipment cavity in the processing process and can be used in medical fields, such as degradable catheters, elastic fascia, artificial skin, and the like.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL +1

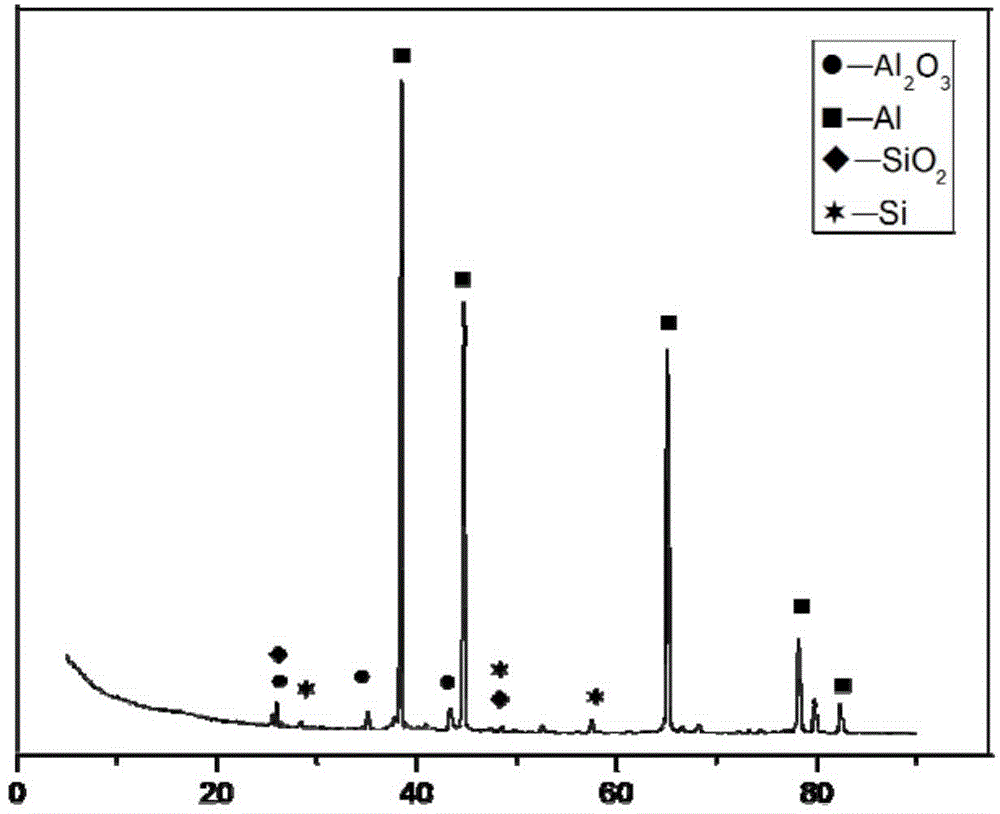

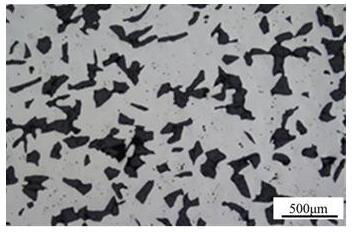

Preparation method of zinc oxide particle strengthened aluminum-based composite

ActiveCN106270509ASimple and fast operationLow costMetal rolling arrangementsZno nanoparticlesTalc / Zinc Oxide

The invention belongs to the field of composites and particularly relates to a preparation method of zinc oxide particle strengthened aluminum-based composite. Zinc oxide is ultrasonically dispersed and evenly applied between pure-aluminum plates that are subjected to full annealing, oxide film removal and degreasing, and the pure-aluminum plates are then subjected to multiple continuous accumulative rolling; a rolled sample is then subjected to discharge plasma sintering process; through strain strengthening and refined crystalline strengthening of the accumulative rolling process and particle strengthening of zinc oxide strengtheners, the composite finally produced has high microhardness about 2.1 times as high as that of an original pure-aluminum sample and also has high heat conductivity and low thermal expansion coefficient. The preparation method has low cost and good safety and reliability and is easy to perform, crystalline grains in the obtained aluminum-based nano composite structure are small, and the nano zinc oxide strengthening phase is evenly distributed with no evident clustering.

Owner:WUHAN UNIV

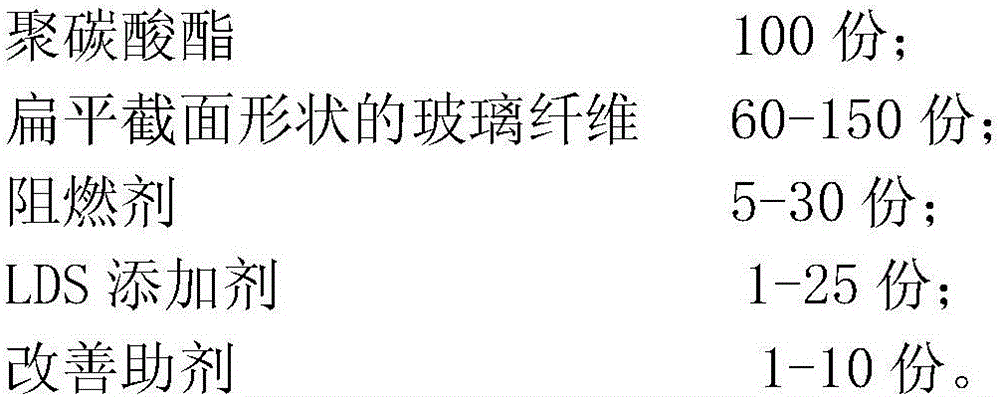

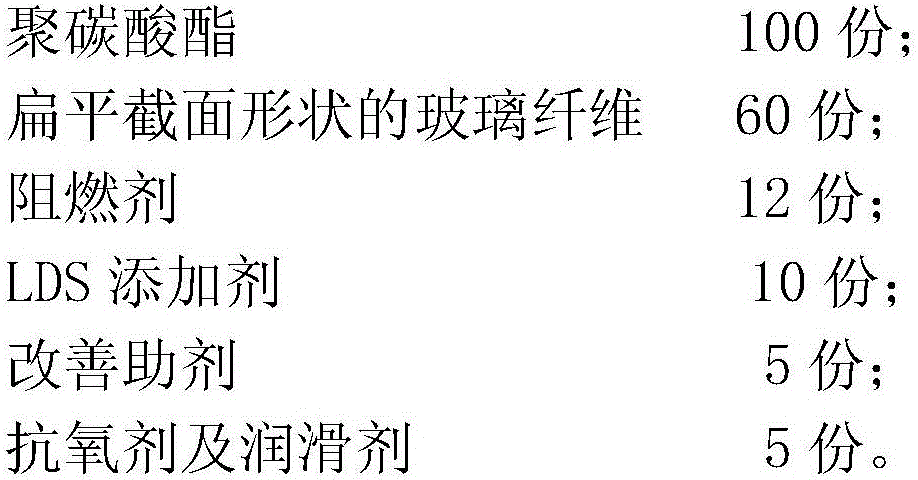

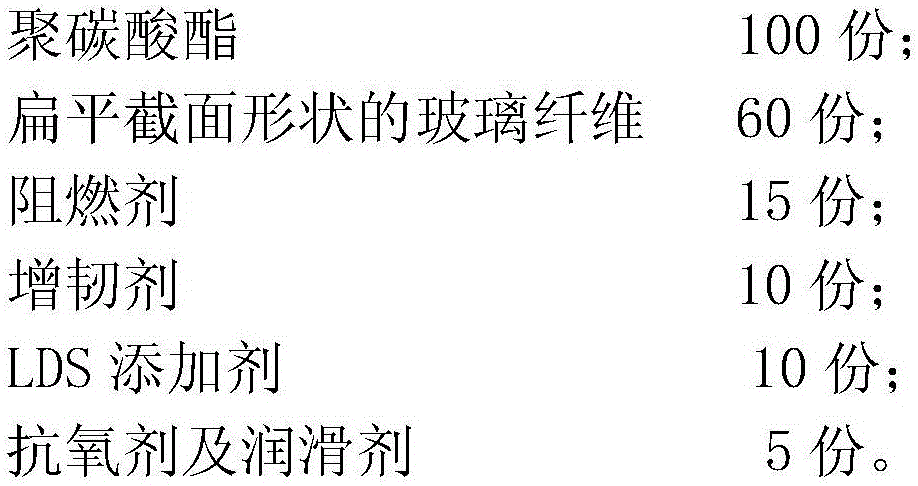

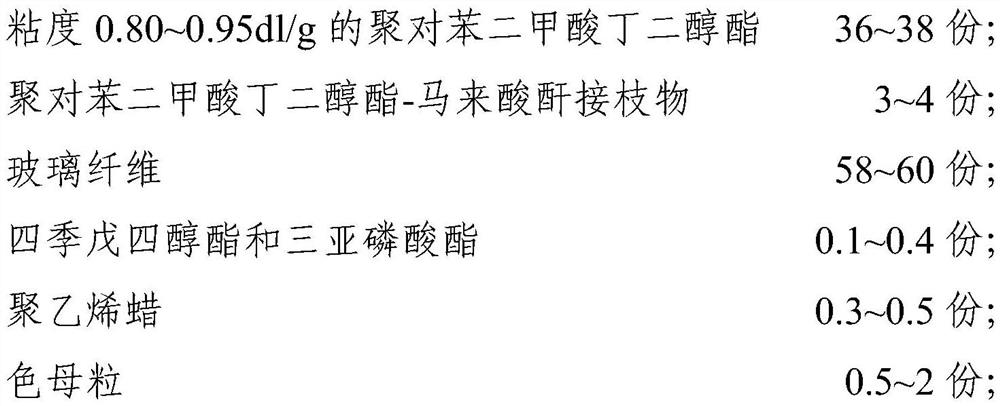

High-physical-property glass fiber reinforced polycarbonate resin composition and product thereof

InactiveCN107177181AHigh strengthImprove rigidityAdditive manufacturing apparatusGlass fiberPolycarbonate

The present invention relates to the technical field of polymer materials, in particular to a high-physical fiberglass-reinforced polycarbonate resin composition for laser direct molding and its products. The composition is expressed in parts by weight: polycarbonate 100 60-150 parts of glass fiber with flat section shape; 5-30 parts of flame retardant; 1-25 parts of LDS additive; 1-10 parts of improving additive. The product is a product produced after laser direct molding of a high physical property glass fiber reinforced polycarbonate resin composition. The high physical property glass fiber reinforced polycarbonate resin composition and its products of the present invention enable the composition to maintain excellent mechanical strength while ensuring LDS activity, so that it can be applied to the structural parts of thin-walled products and expand the application range.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

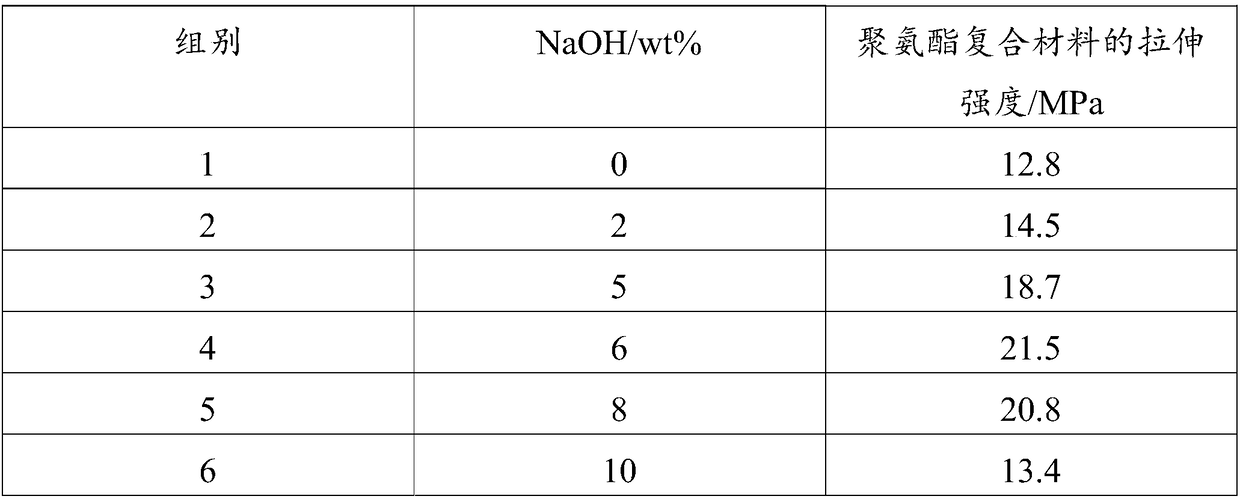

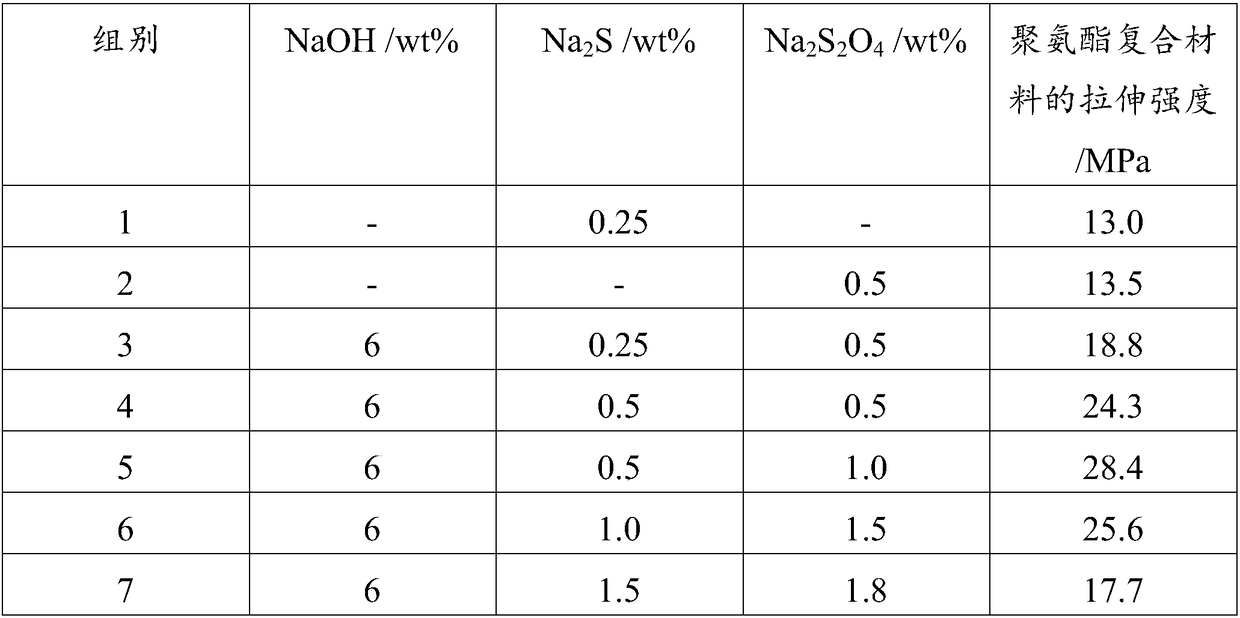

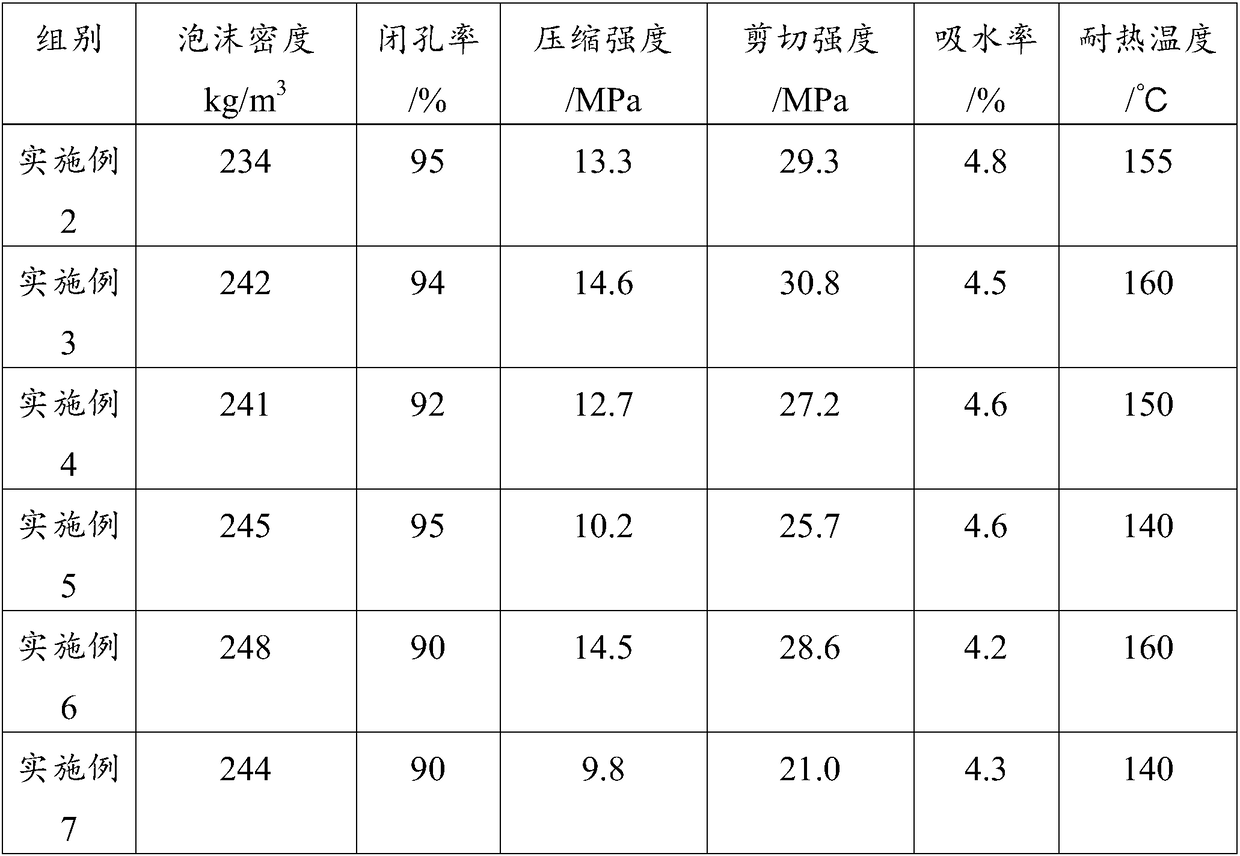

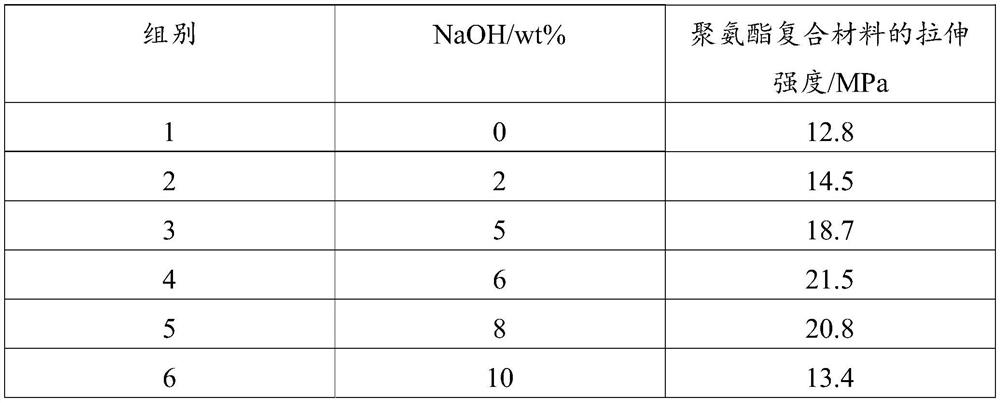

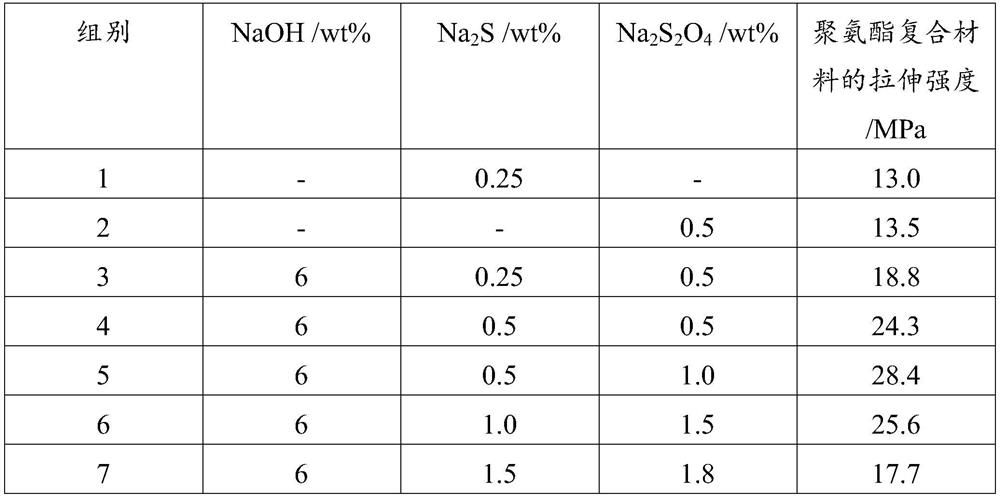

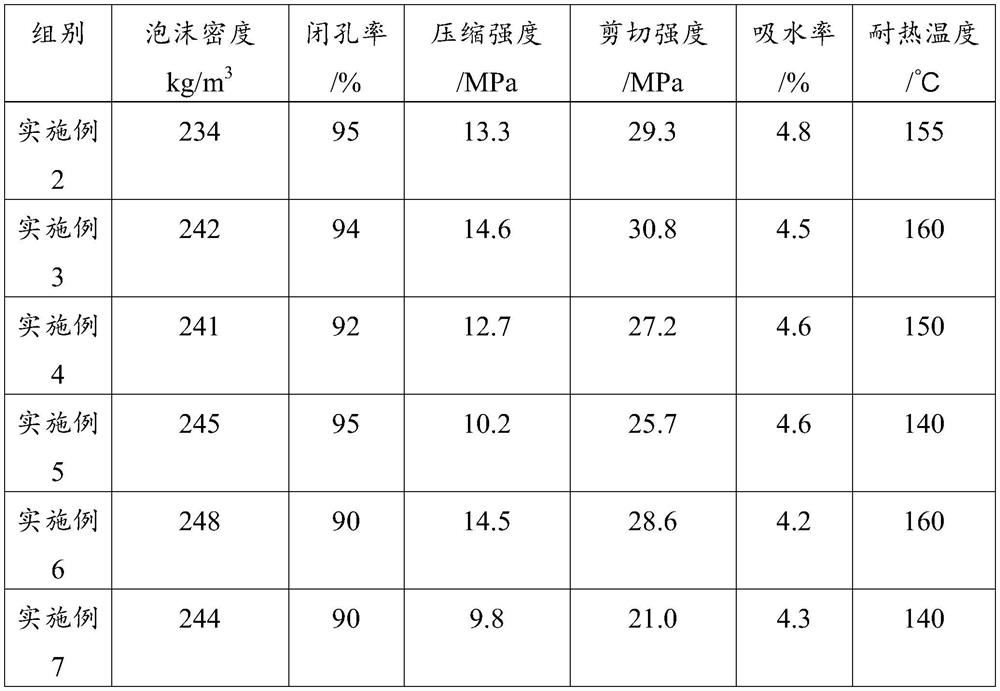

Surface-modified and fiber-reinforced polyurethane composite material and preparation method thereof

The invention discloses a surface-modified and fiber-reinforced polyurethane composite material and a preparation method thereof. The composite material comprises the following components in parts byweight: 100 parts of compound polyether polyol, 0.3-1.5 parts of silicone oil, 0.8-1.4 parts of a catalyst, 1-3 parts of a coupling agent, 6.7-12.5 parts of a compound foaming agent, 4-9 parts of a fire retardant, 27-36 parts of isocyanate, and 12-20 parts of surface modifying palm fibers. According to the surface-modified and fiber-reinforced polyurethane composite material, the surface modifyingpalm fibers are used for preparing the fiber-reinforced polyurethane composite material; the palm fibers are high in elasticity, high in toughness, and high in breaking tenacity, so that the strengthof the polyurethane composite material is improved; the palm fibers are subjected to surface modification, so that the boundary combination condition of the fibers and a material substrate can be improved. The surface-modified and fiber-reinforced polyurethane composite material are relatively high in mechanical strength and high in fireproof and flame retarding performances.

Owner:VESACH FURNITURE & DECORATION

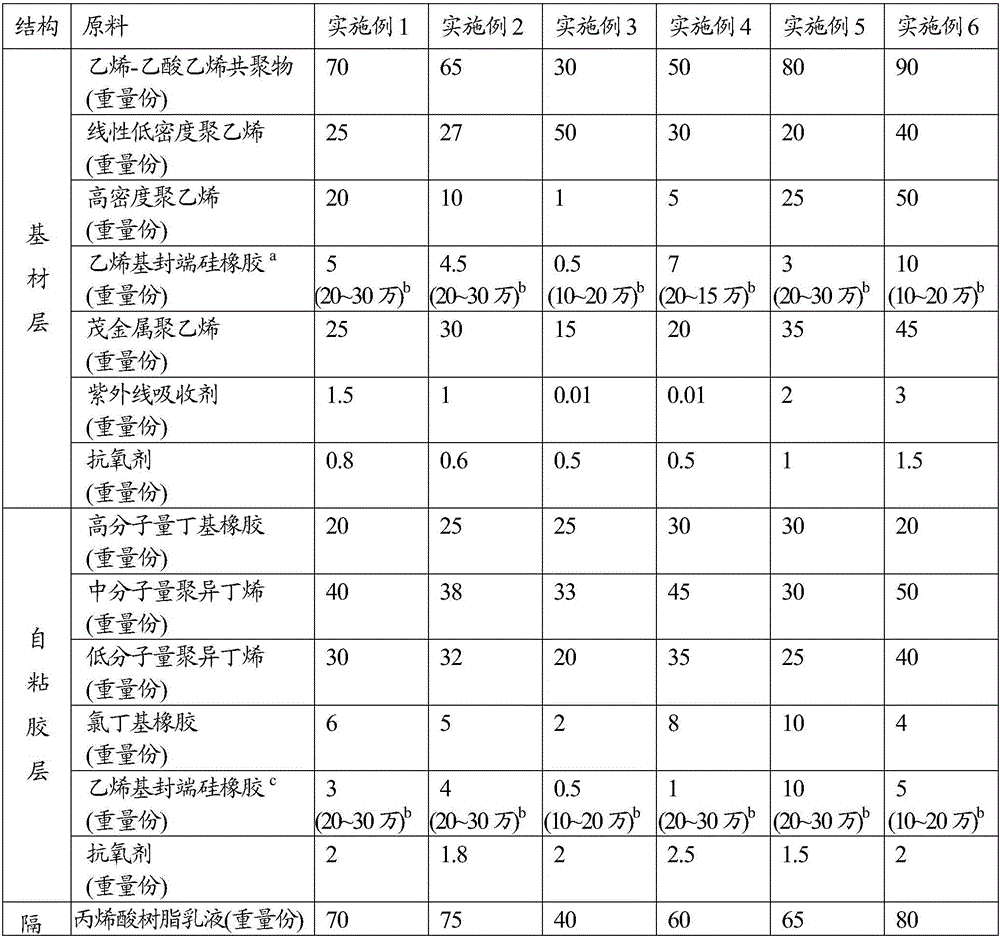

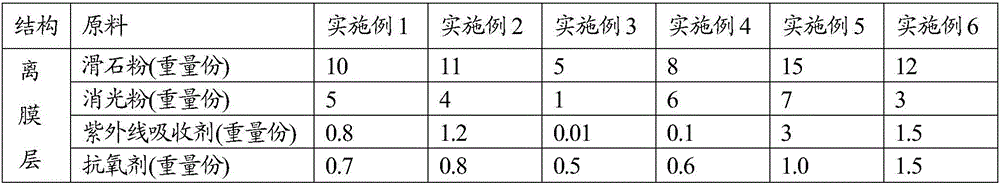

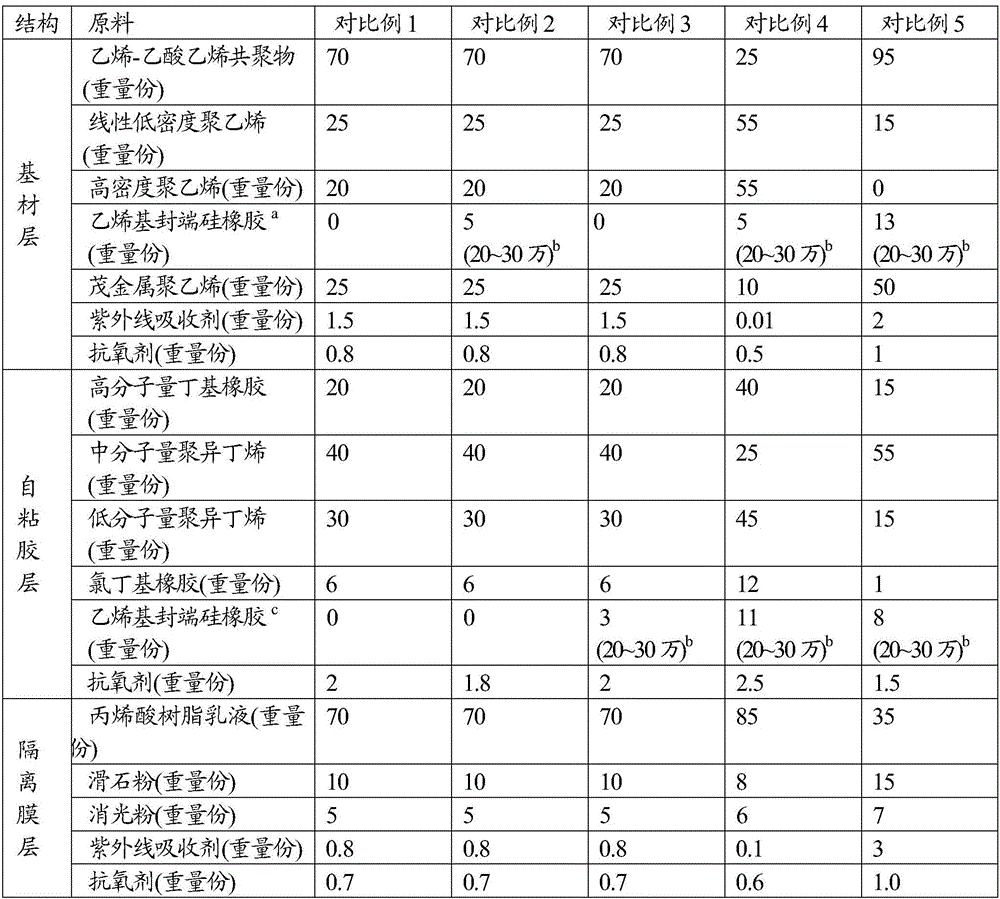

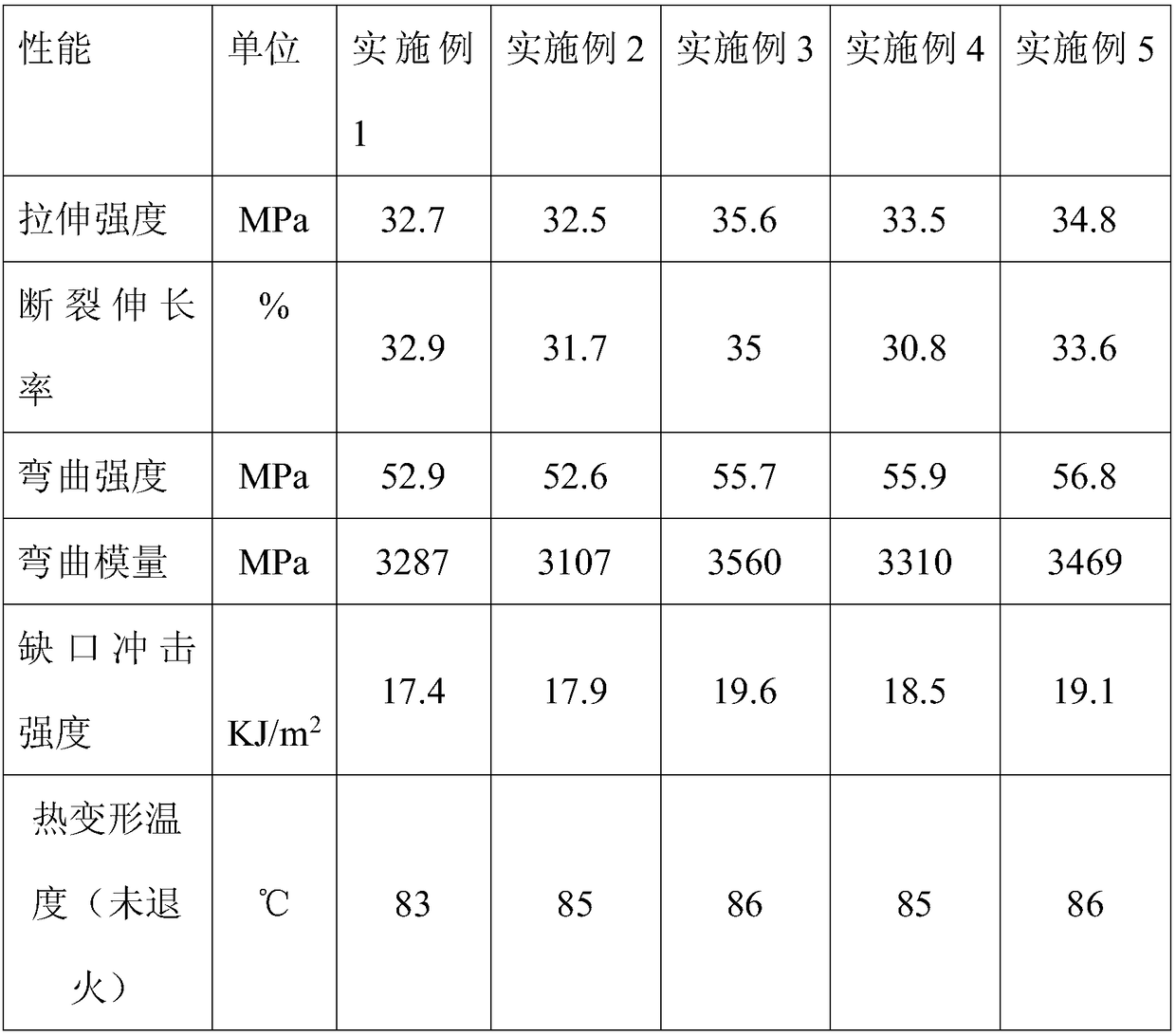

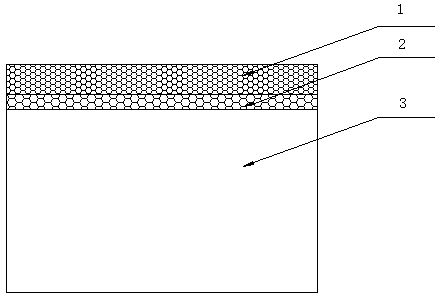

Anti-stick waterproof board and preparation method thereof

ActiveCN106700216AImprove adhesionImprove waterproof performanceUnderground chambersCoatingsPolymer scienceAntioxidant

The invention provides an anti-stick waterproof board with excellent water resistance. The anti-stick waterproof board consists of a base material layer, a self-adhesive layer and an isolating membrane layer which are sequentially compounded into a whole, wherein the self-adhesive layer is positioned between the base material layer and the isolating membrane layer; the isolating membrane layer does not need to be removed, and disappears after reacting with poured concrete; the self-adhesive layer has the thickness of 0.2-0.4mm, and is prepared from the following components in parts by weight: 2-10 parts of chlorobutyl rubber, 20-30 parts of high-molecular-weight butyl rubber with a viscosity average molecular weight of 400-500 thousands, 30-50 parts of medium-molecular-weight polyisobutylene with a viscosity average molecular weight of 50-100 thousands, 20-40 parts of low-molecular-weight polyisobutylene with a viscosity average molecular weight of 1000-3000, 0.5-10 parts of vinyl-terminated silicone rubber and 1-5 parts of an antioxidant; the vinyl-terminated silicone rubber is terminal vinyl silicone rubber and has a viscosity average molecular weight of 50-300 thousands, and the mole percent of vinyl is more than 1%. The invention also provides a preparation method of the anti-stick waterproof board.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

Low-temperature-resistant anti-cracking cable rubber material

InactiveCN107501649AImprove aging resistanceImprove cold resistanceRubber insulatorsRubber materialEpoxy

The invention discloses a low-temperature-resistant anti-cracking cable rubber material, which includes, by weight, 100-120 parts of nitrile butadiene rubber, 20-30 parts of butadiene rubber, 20-40 parts of chloroprene rubber, 60-80 parts of composite filler, 8-10 parts of a composite compatilizer, 40-50 parts of a flame retardant, 4-6 parts of polyethylene wax, 3-4 parts of dibutyl phthalate, 2-3 parts of epoxy butyl furoate, 0.5-1.5 parts of vinyltriethoxysilane, 1.5-2.5 parts of a vulcanizer, 0.2-0.4 parts of a promoter CZ, 0.2-0.4 parts of a promoter BZ, 0.5-0.7 parts of an anti-aging agent RD, and 0.4-0.6 parts of an anti-aging agent MB. The cable rubber material has excellent oil resistance, wear resistance, anti-aging property, cold resistance, anti-impact property and anti-crack performance.

Owner:ANHUI CHAOYUE TECH

Special impact-resistant polystyrene material for new-energy vehicles and preparation method of material

The invention provides a special impact-resistant polystyrene material for new-energy vehicles and a preparation method of the material and relates to the technical field of high-polymer materials. The special impact-resistant polystyrene material for the new-energy vehicles is prepared from the following raw materials: high-impact-resistance polystyrene resin, acrylate epoxy resin, polyurethane elastomers, modified fibers, graphene oxide, nano talc, triphenyl phosphate, isophorone diisocyanate, tris(2,4-di-tert-butyl-pheny)phosphite, silicone oil, a plasticizer and a toughening agent. The special impact-resistant polystyrene material for the new-energy vehicles has the relatively high impact resistance, tensile strength, heat resistance and bending resistance and can keep the excellent impact resistance in the relatively wide temperature spectrum range.

Owner:WUHU CHUANGKE NEW MATERIAL TECH CO LTD

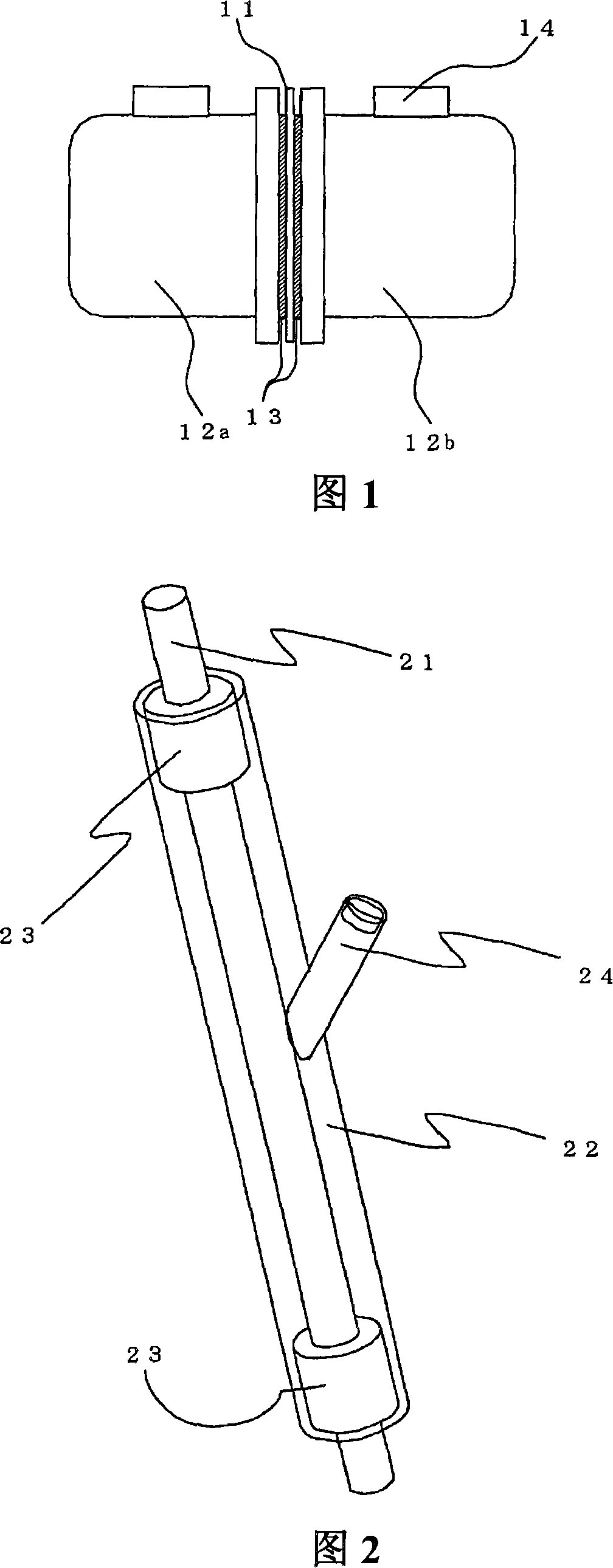

Polycrystalline diamond composite sheet

ActiveCN102174877BImprove interface integrationImprove wear resistanceDrill bitsMetal layered productsPolycrystalline diamondAlloy

Owner:中山市海明润超硬材料有限公司

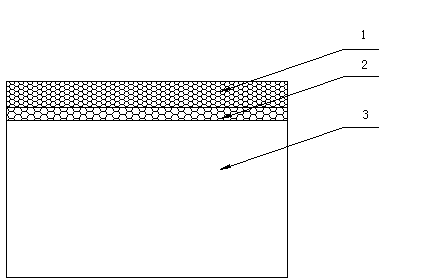

Chlorotrifluoroethylene copolymer containing laminate and process for production thereof

InactiveCN101137504AReduce permeabilityGood lookingSynthetic resin layered productsVinyl etherHexafluoropropylene

A chlorotrifluoroethylene (CTFE) copolymer containing laminate which is produced by coextruding a layer of tetrafluoro- ethylene / perfluoro vinyl ether copolymer (PFA) and / or a tetra- fluoroethylene / hexafluoropropylene copolymer (FEP) and a CTFE copolymer layer with the latter being inhibited from thermal deterioration and which is improved in the resistance to permeation of chemical fluids and so on; and a process for the production of the laminate. The invention relates to a CTFE copolymer containing laminate comprising a layer (A) of PFA and / or FEP and a layer (B) of a CTFE copolymer, characterized by being produced by coextruding the layers (A) and (B) under such conditions that in the stage before the contact of material (a) for the layer (A) with material (b) for the layer (B) in a multilayer die, the temperature of a passageway (pa) through which the material (a) flows lies within the range of 300 to 400 DEG C and the temperature of a passageway (pb) through which the material (b) flows lies within the range of 250 to 350 DEG C.

Owner:DAIKIN IND LTD

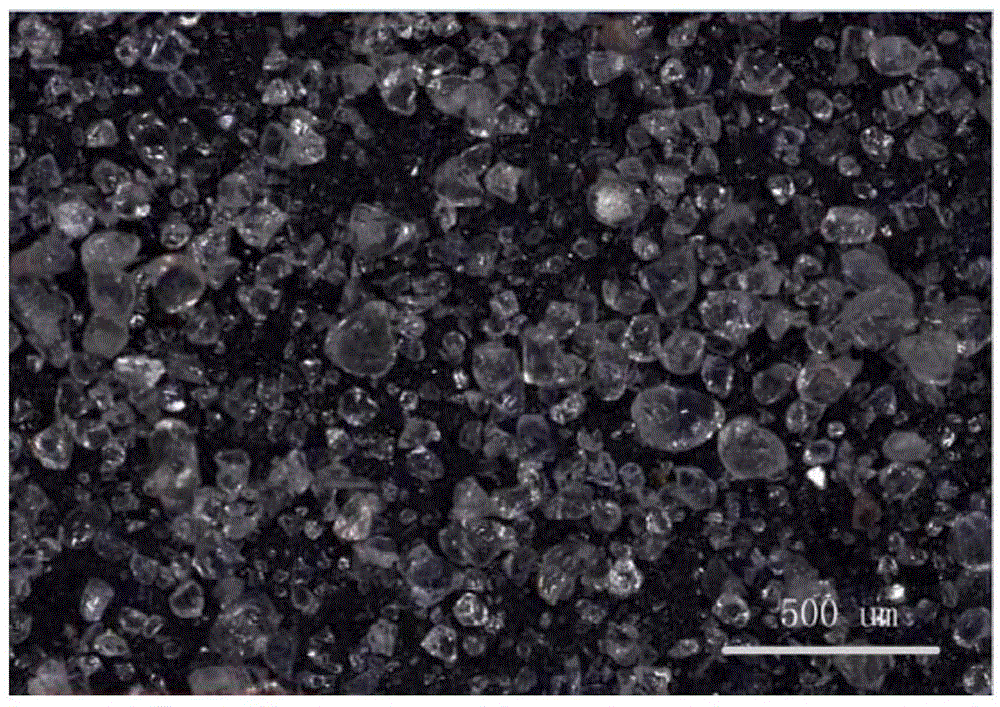

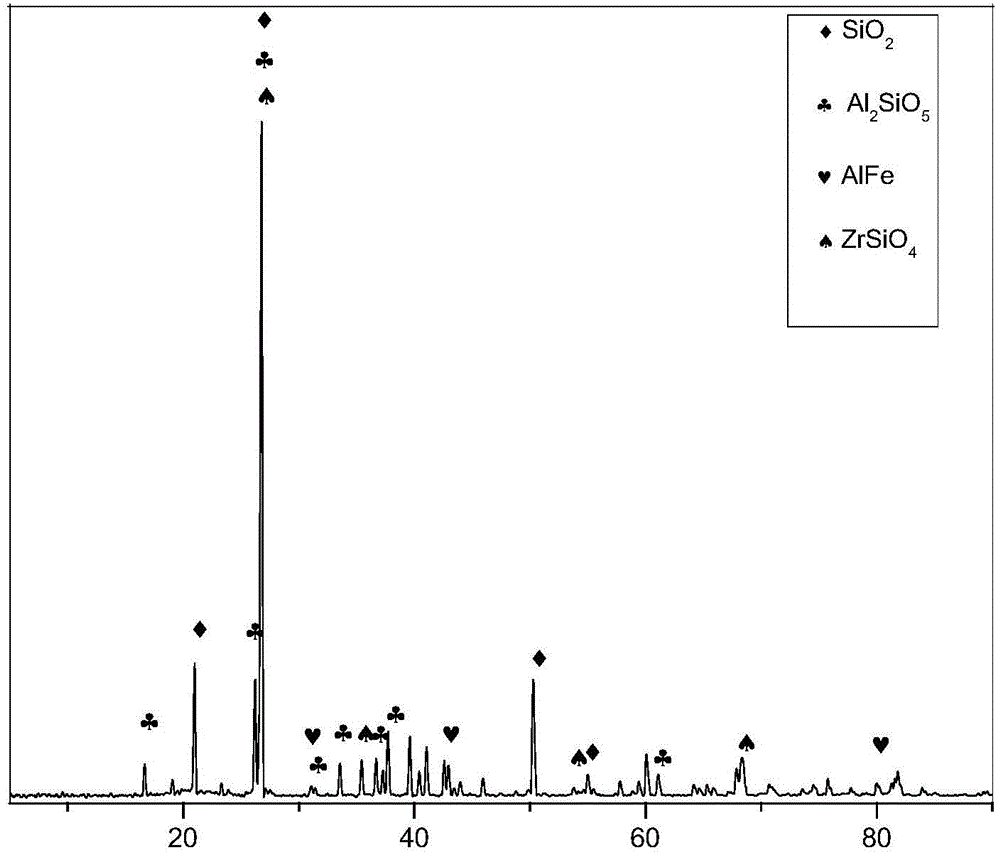

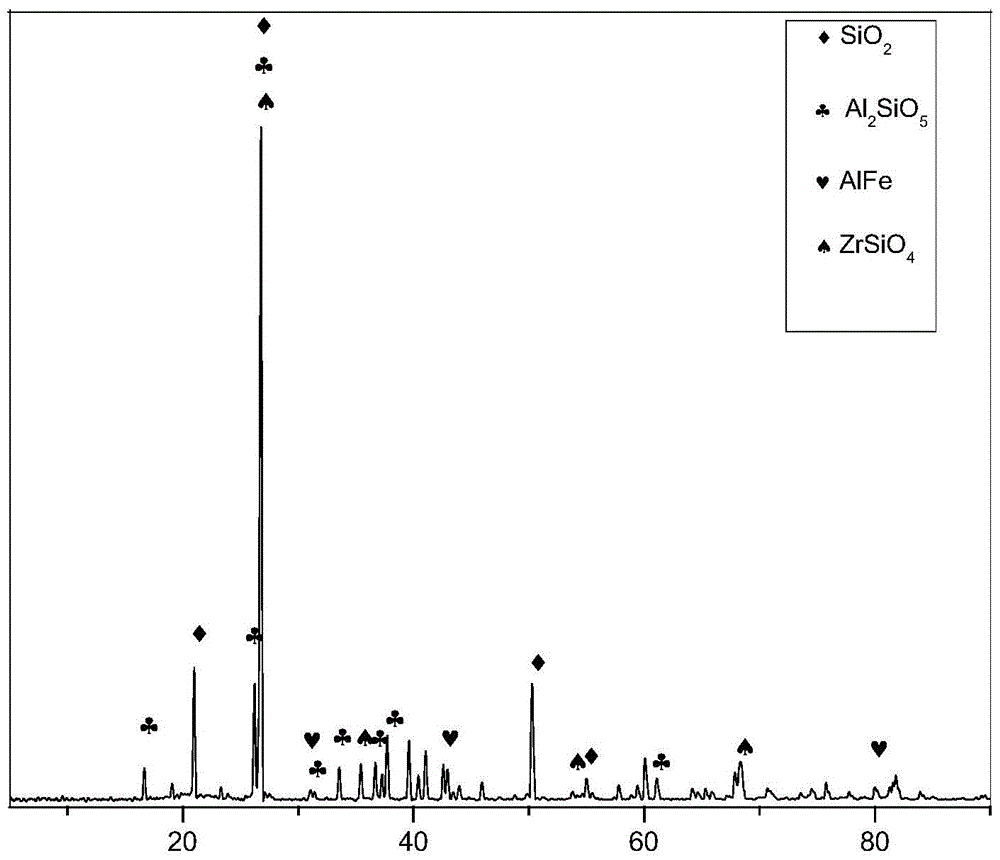

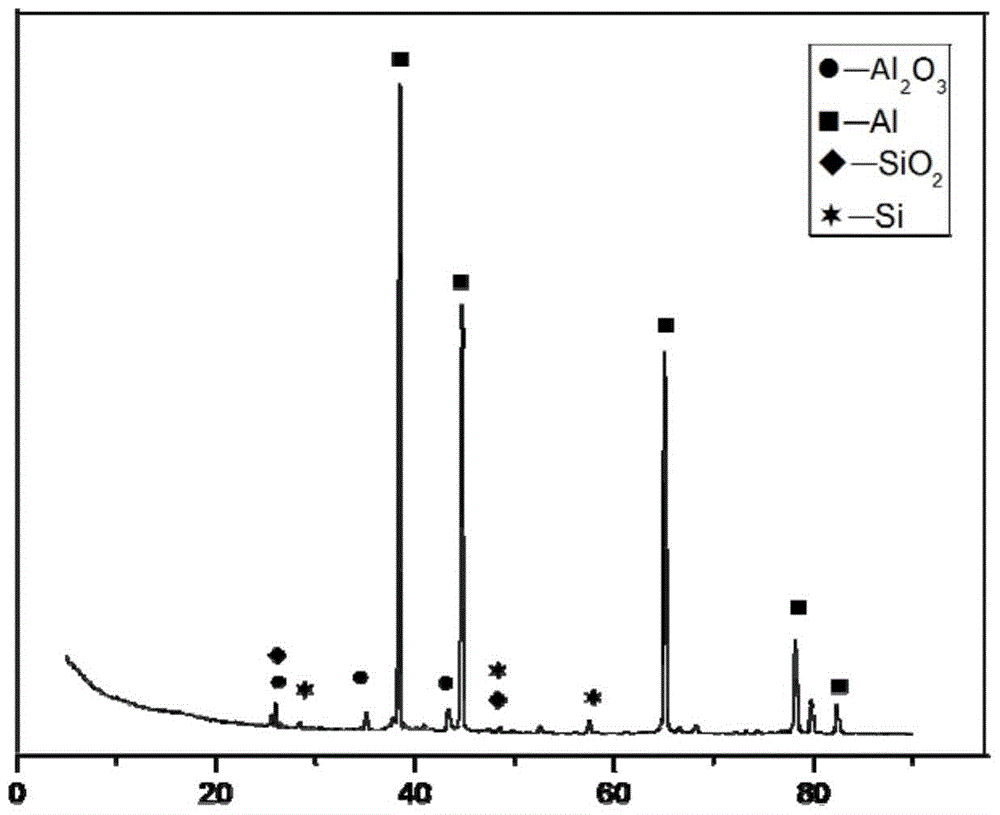

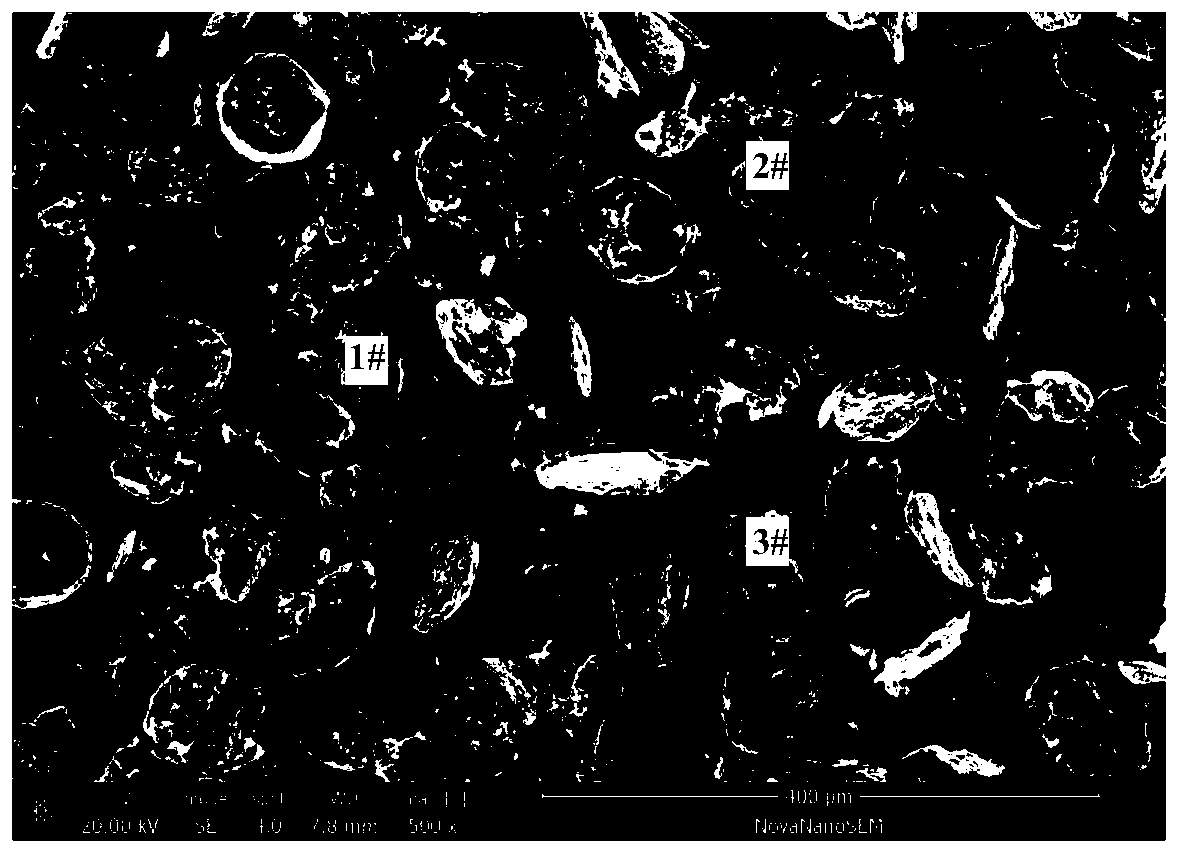

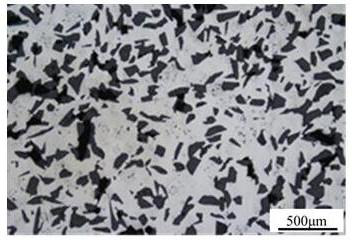

Preparation method of in-situ particle reinforced aluminum-based composite material

The invention discloses a preparation method of an in-situ particle reinforced aluminum-based composite material. The preparation method comprises the following steps: firstly, performing pretreatment on uhligite tailings, namely screening the uhligite tailings by use of a specific gravity method before ball milling, then screening by use of a screen to obtain the uhligite tailings having the particle diameter ranging from 150 microns to 180 microns, and drying to obtain tailing addition particles; secondly, adding the tailing addition particles to pure aluminum by use of a stirring casting method to obtain the in-situ particle reinforced aluminum-based composite material. The adopted uhligite tailings are relatively high in SiO2 content, and also contain aluminum silicate having positive contribution to the mechanical properties of the composite material; seen from the microstructure of the material, the reinforcing body is well bonded with the substrate and the reinforcing body is evenly distributed; the addition amount of the reinforcing body is easy to control, and the prepared composite material shows excellent mechanical properties.

Owner:SOUTH CHINA UNIV OF TECH

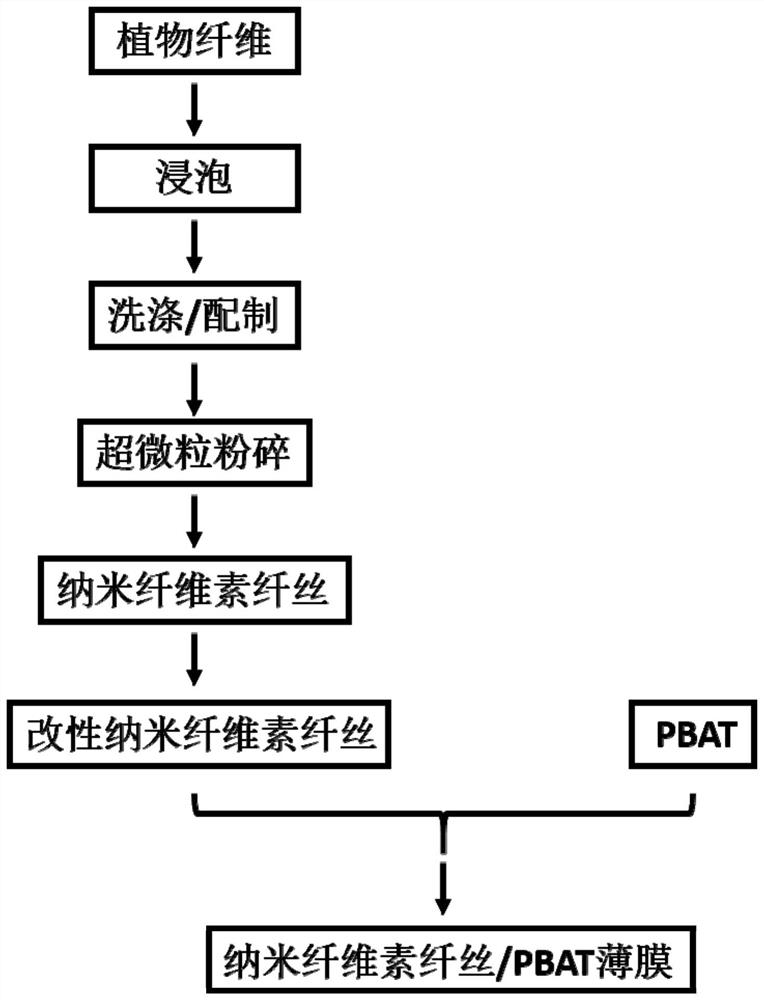

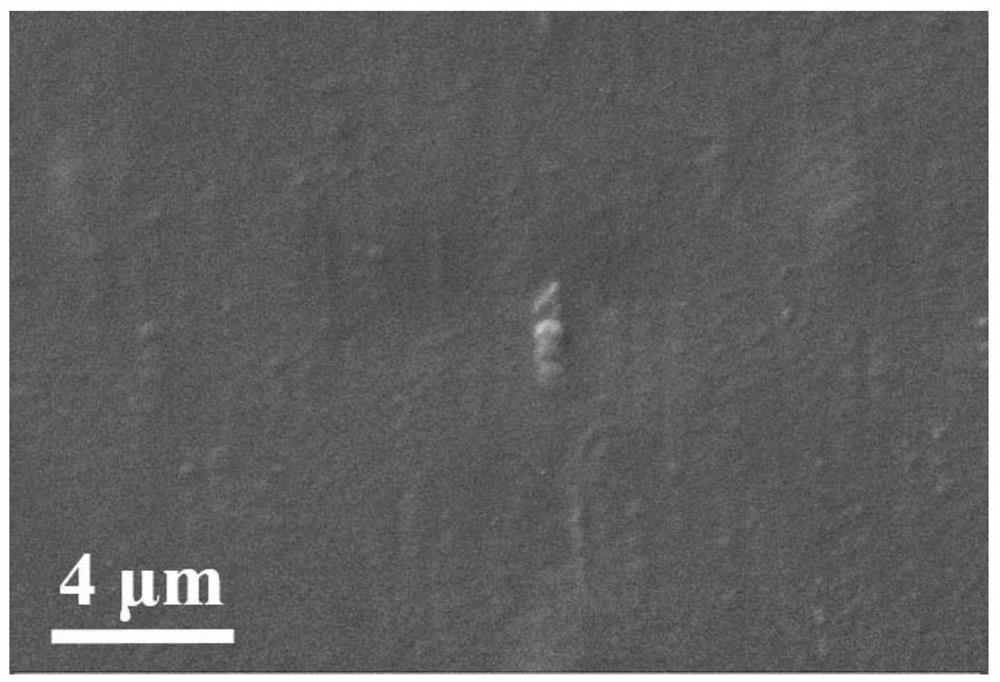

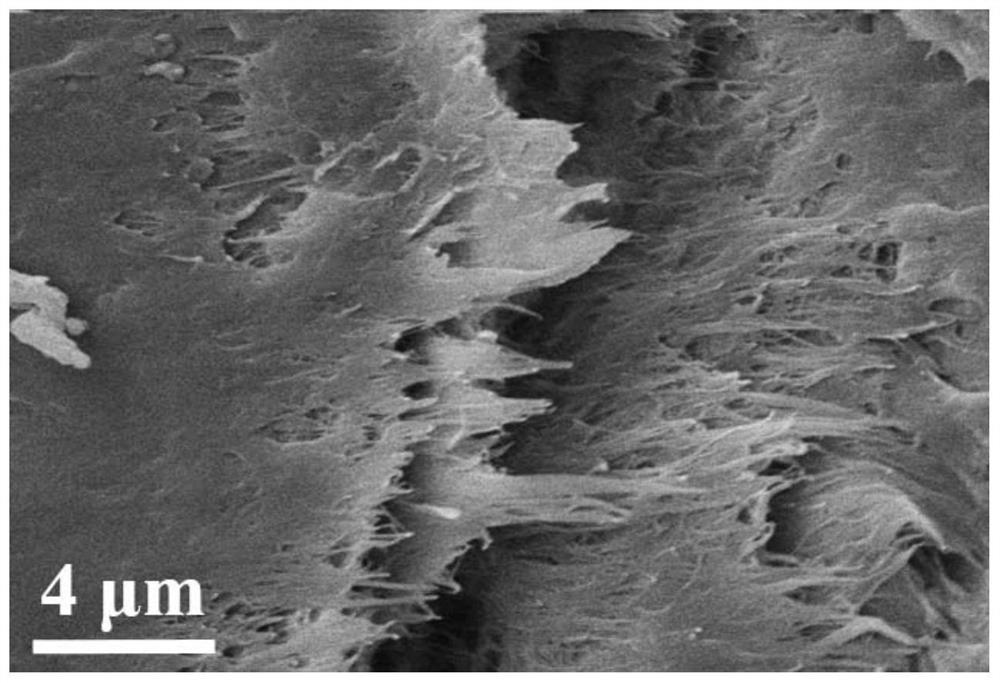

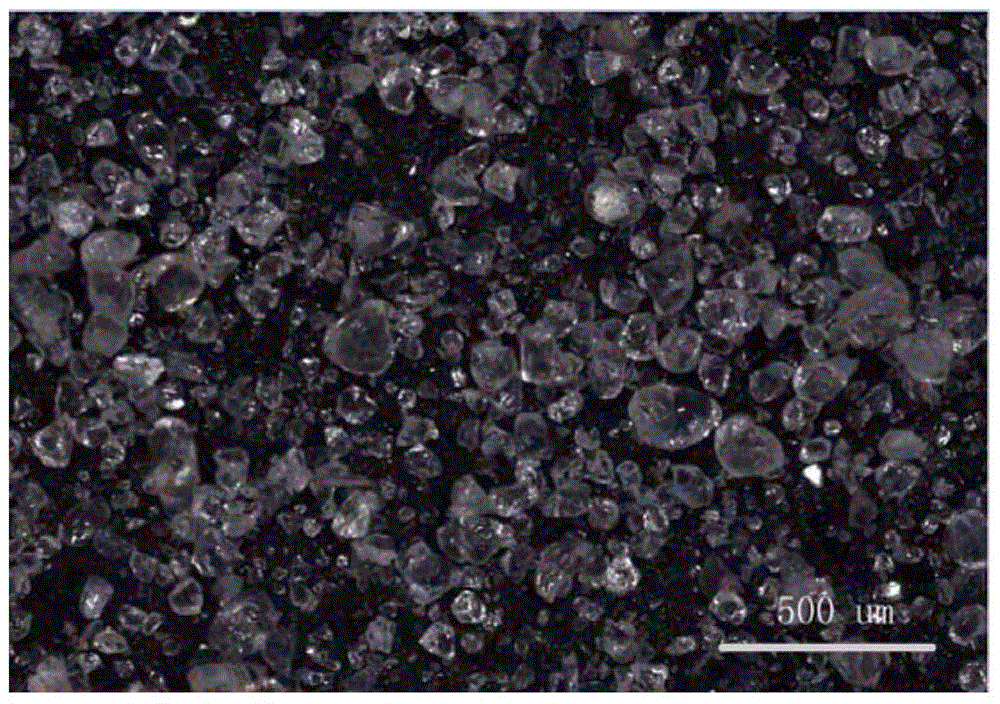

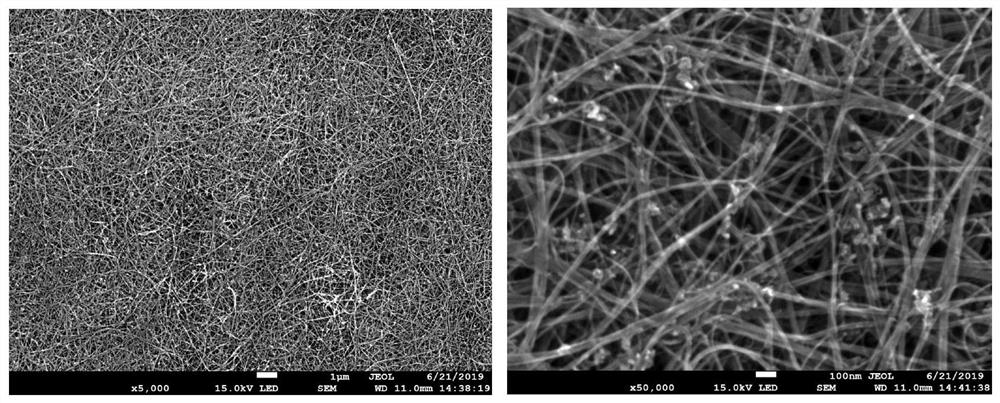

Nano-cellulose fibril /PBAT film and preparation method and application thereof

ActiveCN111925631AGood dispersion propertiesGood dispersionBio-packagingVegetal fibresPolymer scienceComposite film

The invention discloses a nano cellulose fibril / PBAT film and a preparation method and application thereof. The preparation method of the nano cellulose fibril / PBAT film comprises the following steps:(1) soaking and washing plant cellulose paper pulp in a buffer solution to prepare a plant cellulose paper pulp suspension I; (2) then crushing by adopting an ultrafine particle crusher to obtain nano cellulose fibrils of a water dispersion system; (3) carrying out centrifugal washing by using an organic solvent, then carrying out modification treatment, and then washing to prepare an organic solution; and (4) finally mixing with PABT, and preparing the nano cellulose fibril / PABT composite film by a tape casting method. According to the invention, the nano cellulose fibrils are prepared by asimple mechanical method, the nano cellulose fibril / PBAT composite film is prepared by modification treatment, and the nano cellulose fibril / PBAT composite film has good biodegradability and mechanical properties, and is simple to operate. The film has potential application value in packaging and agriculture.

Owner:SOUTH CHINA UNIV OF TECH

A kind of preparation method of in-situ particle reinforced aluminum matrix composite material

The invention discloses a preparation method of an in-situ particle reinforced aluminum-based composite material. The preparation method comprises the following steps: firstly, performing pretreatment on uhligite tailings, namely screening the uhligite tailings by use of a specific gravity method before ball milling, then screening by use of a screen to obtain the uhligite tailings having the particle diameter ranging from 150 microns to 180 microns, and drying to obtain tailing addition particles; secondly, adding the tailing addition particles to pure aluminum by use of a stirring casting method to obtain the in-situ particle reinforced aluminum-based composite material. The adopted uhligite tailings are relatively high in SiO2 content, and also contain aluminum silicate having positive contribution to the mechanical properties of the composite material; seen from the microstructure of the material, the reinforcing body is well bonded with the substrate and the reinforcing body is evenly distributed; the addition amount of the reinforcing body is easy to control, and the prepared composite material shows excellent mechanical properties.

Owner:SOUTH CHINA UNIV OF TECH

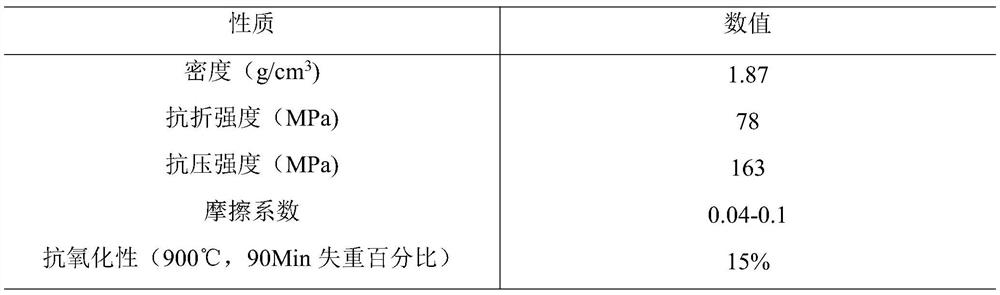

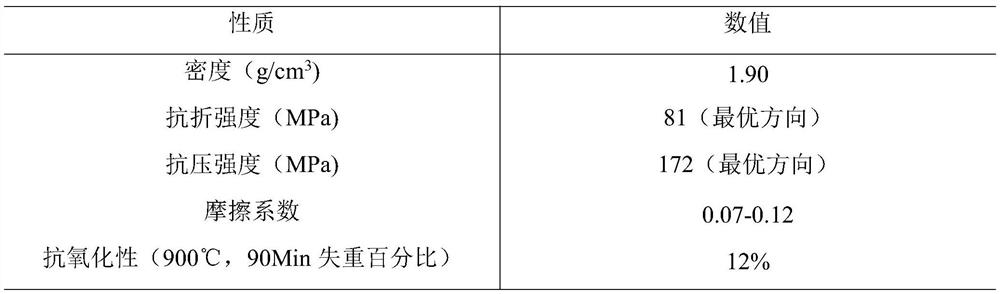

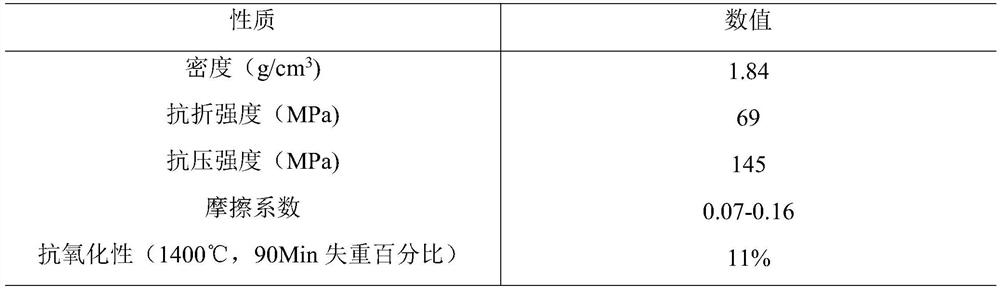

Preparation method of ceramic powder doped modified self-sintering graphite composite material

The invention discloses a preparation method of a ceramic powder doped modified self-sintering graphite composite material, belongs to the technical field of preparation of special graphite composite materials, and solves the problems that ceramic particles are difficult to disperse in raw material pressed powder, the efficiency is low, and the interface bonding strength of a matrix phase and a ceramic phase is poor. According to the method, the ceramic powder is introduced into the raw material for preparing the graphite through an in-situ coating method, so that the phenomenon of non-uniform distribution of ceramic particles is effectively improved, and effective carbon coating can be formed on the ceramic particles, so that the microcosmic interface of the material is improved. In the material preparation process, firstly, the ceramic powder is added into the modified asphalt to serve as a nucleating agent to promote liquid-phase semi-carbonization of the modified asphalt, and green coke coated composite ceramic powder is prepared; the surface green coke has the self-sintering property, so that the ceramic component and the carbon component of the material can be synchronously shrunk and densified in the subsequent heat treatment process, and finally the ceramic doped modified self-sintered graphite composite material with uniform ceramic particle distribution, high interface bonding strength and excellent comprehensive performance is prepared.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

In-situ fiber-forming strengthened degradable medical elastic composite material and preparation method thereof

ActiveCN101623516BHigh tensile strengthAppropriate compatibilityCatheterProsthesisPoly-L-lactideFiber

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL +1

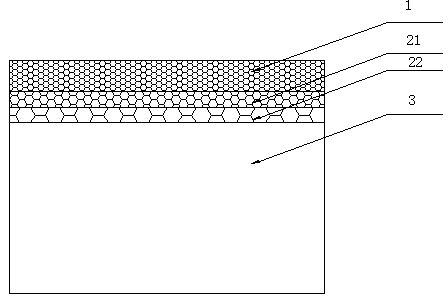

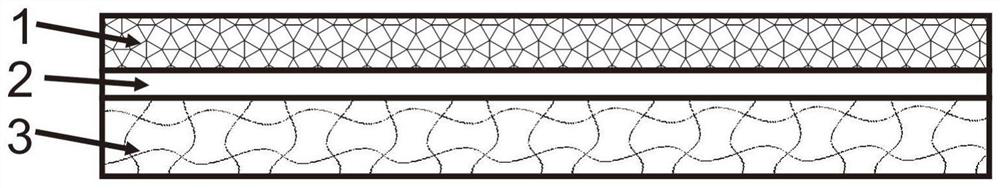

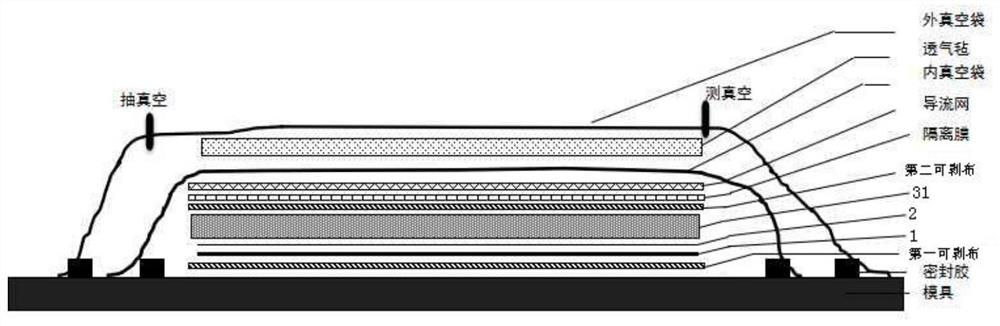

Forming method of carbon nanotube film/composite material and lightning protection structure

ActiveCN110744833BImprove conductivityLow densityProtective equipmentLayered productsFiberCarbon nanotube

The invention belongs to the technical field of lightning protection of aircraft composite materials, and in particular relates to a carbon nanotube film / composite material forming method and a lightning protection structure made therefrom. The molding method adopts a low-cost liquid molding one-step method to obtain an ultra-light carbon nanotube film / composite material lightning protection structure as a whole. The lightning protection structure includes: a carbon nanotube film used as a conductive layer; a composite material including fibers and resin filled in the fibers; an adhesive film used for electrical insulation between the composite material and the carbon nanotube film ; The carbon nanotube film, adhesive film and composite material are arranged in sequence. The lightning protection structure can be integrally formed in one step.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

Composite 3D printing material and preparation method thereof

InactiveCN108192373AHigh tensile strengthImprove heat resistanceAdditive manufacturing apparatusPolymer scienceEthyl acetate

The invention discloses a composite 3D printing material and a preparation method thereof and relates to the technical field of 3D printing materials. The composite 3D printing material comprises thefollowing raw materials in part by weight: 30-50 parts of photosensitive resin, 15-30 parts of modified aramid pulp, 12-20 parts of talcum powder, 8-15 parts of pigment, 5-10 parts of polycaprolactone, 2-5 parts of aliphatic diester, 6-12 parts of ethyl acetate, 2-5 parts of a lubricating agent and 1-4 parts of a coupling agent. The composite 3D printing material prepared by the preparation methoddisclosed by the invention is easy for 3D printing, and a printed product has higher toughness, adhesiveness and impact strength.

Owner:WUHU LINYI ELECTRONICS SCI & TECH

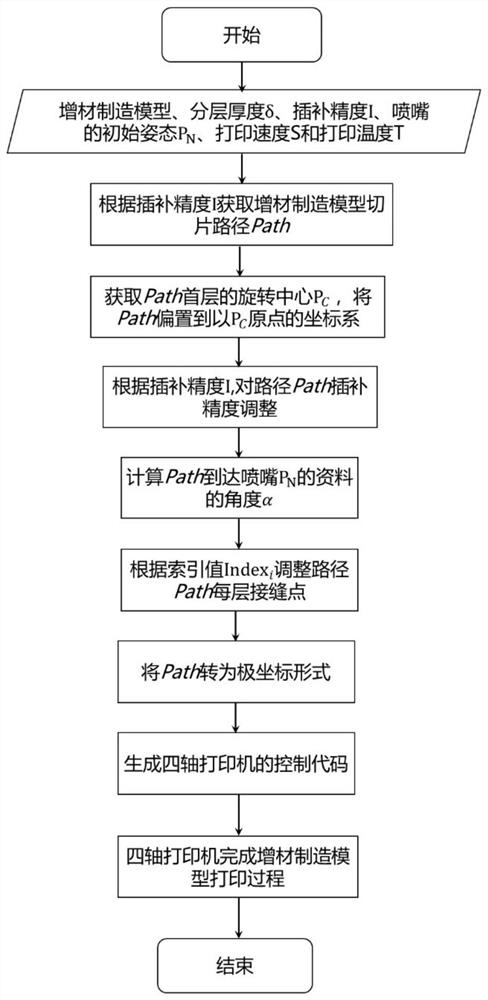

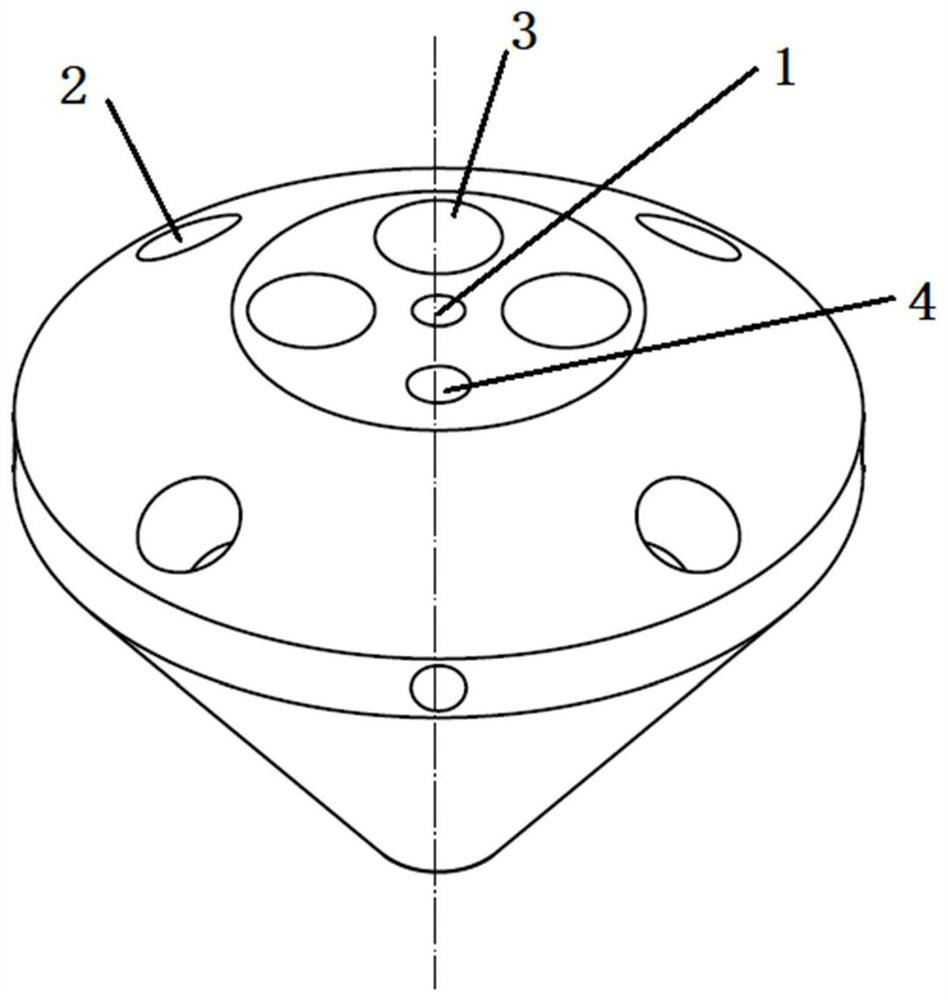

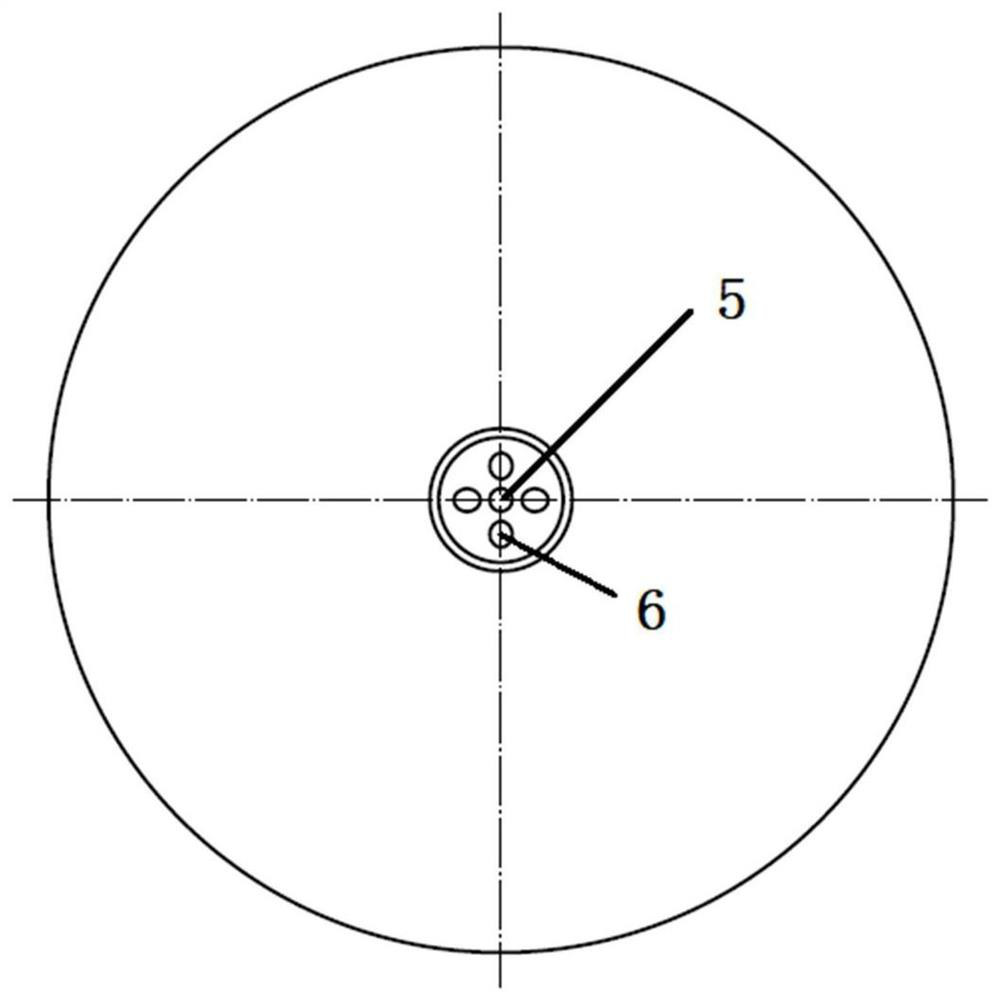

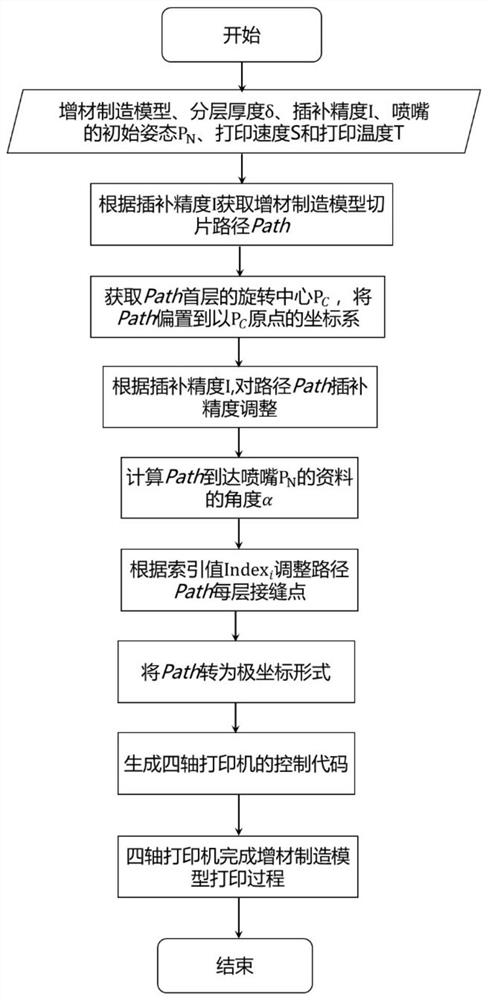

In-situ manufacturing method of continuous fiber reinforced soft and hard mixed thermoplastic-based component

ActiveCN113601835AImprove mechanical propertiesImprove interface integrationManufacturing driving meansAdditive mnaufacturing with solid and fluidThermoplasticComputer printing

The invention discloses an in-situ manufacturing method of a continuous fiber reinforced soft and hard mixed thermoplastic-based component. The in-situ manufacturing method comprises the following steps of (1) inputting a model needing additive manufacturing and process parameters; (2) slicing the input model to obtain an initial slicing path with n layers; (3) calculating to obtain a central point Pc of a first layer of the slicing path, and offsetting the slicing path Path to a coordinate system taking the Pc as an original point; (4) interpolating the path of each layer to a specified precision, wherein the interpolated path is PathI; (5) calculating the angle theta required by the PathI to reach the specified attitude alpha of a nozzle, and readjusting the seam between the starting point and the end point of each layer of path of the PathI to obtain Pathend; and (6) converting the Pathend into polar coordinates to be expressed, printing paths Px, y, z and generating theta of a four-axis printer, and generating control codes of the four-axis printer according to the printing speed S and the nozzle control temperature T. According to the in-situ manufacturing method, the problems of poor mechanical property and poor interface fusion of the soft and hard mixed material are solved.

Owner:ZHEJIANG UNIV

A kind of surface modified fiber reinforced polyurethane composite material and preparation method thereof

Owner:VESACH FURNITURE & DECORATION

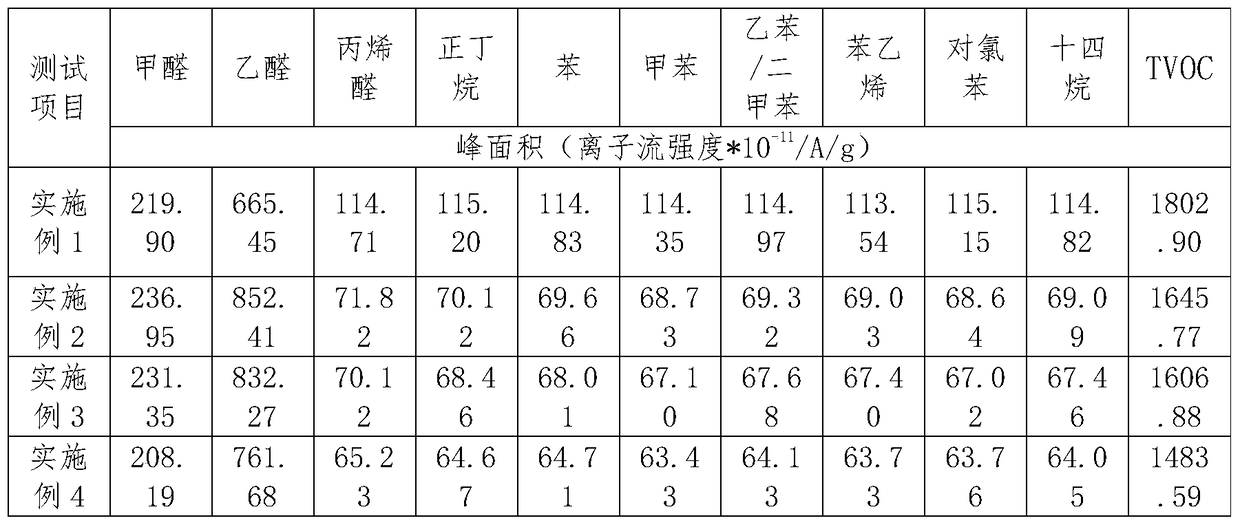

A kind of low VOC natural fiber composite material, preparation method and application thereof

The invention discloses a low-VOC natural fiber composite material, a preparation method and an application thereof. In the method, a VOC capture agent is sprayed into a mixed fiber of natural fiber and polypropylene after opening; the sprayed natural fiber The mixed fiber of fiber and polypropylene is processed into a fiber mat through a carding and needle-punching process; and the fiber mat is subjected to a heat-pressing process to prepare the low-VOC natural fiber composite material. The invention reduces the release amount of VOC of the natural fiber composite material by adding a VOC capture agent in the preparation process of the natural fiber composite material, and at the same time greatly improves the mechanical properties of the natural fiber composite material.

Owner:CHANGCHUN BOCHAO AUTOMOTIVE PARTS CO LTD

A thermoplastic polymer composite material with high nail-holding force and its preparation method and application

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL +1

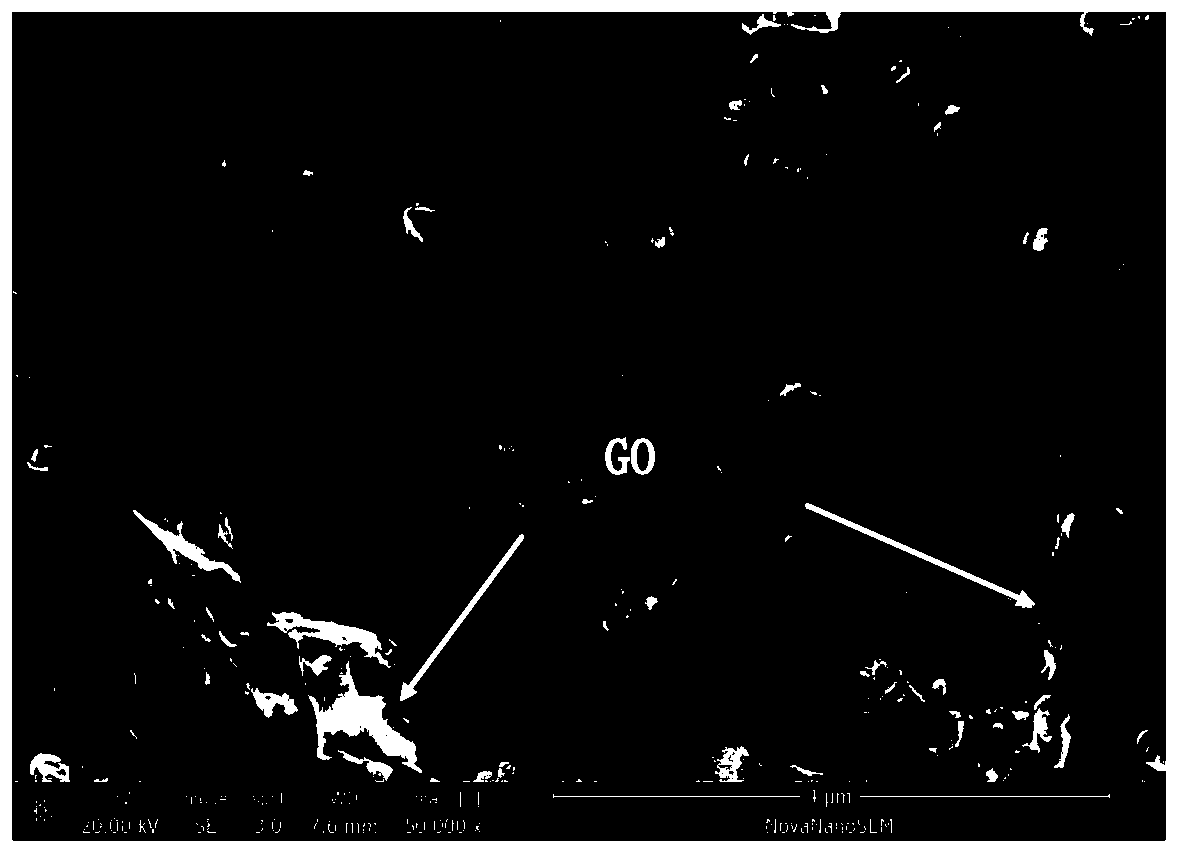

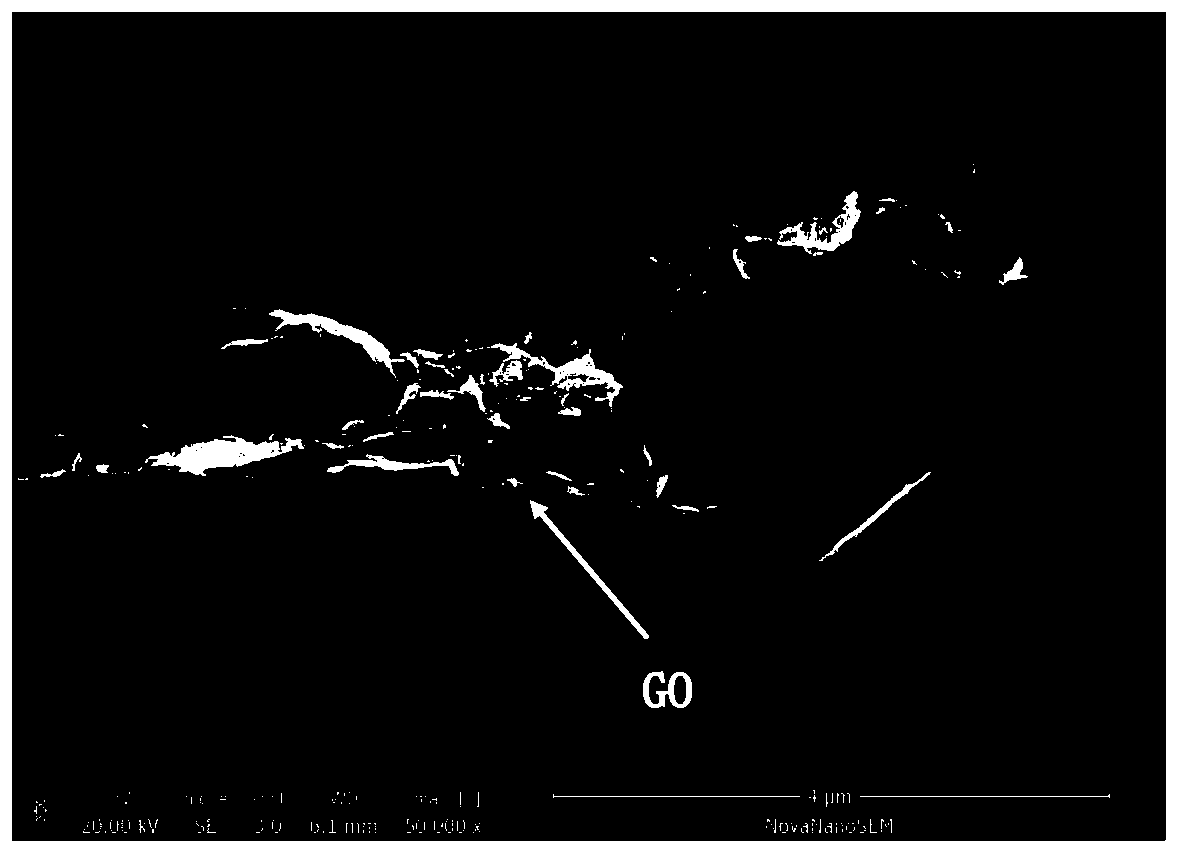

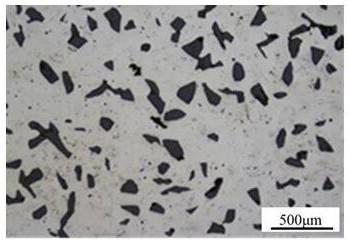

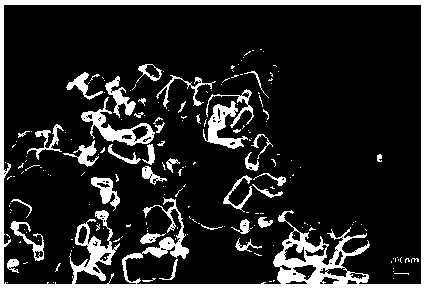

Preparation method of graphene surface cobalt plating reinforced cobalt-based alloy composite powder for selective laser melting forming

PendingCN113634744AImprove performanceGood dispersionAdditive manufacturing apparatusSelective laser meltingCobalt metal

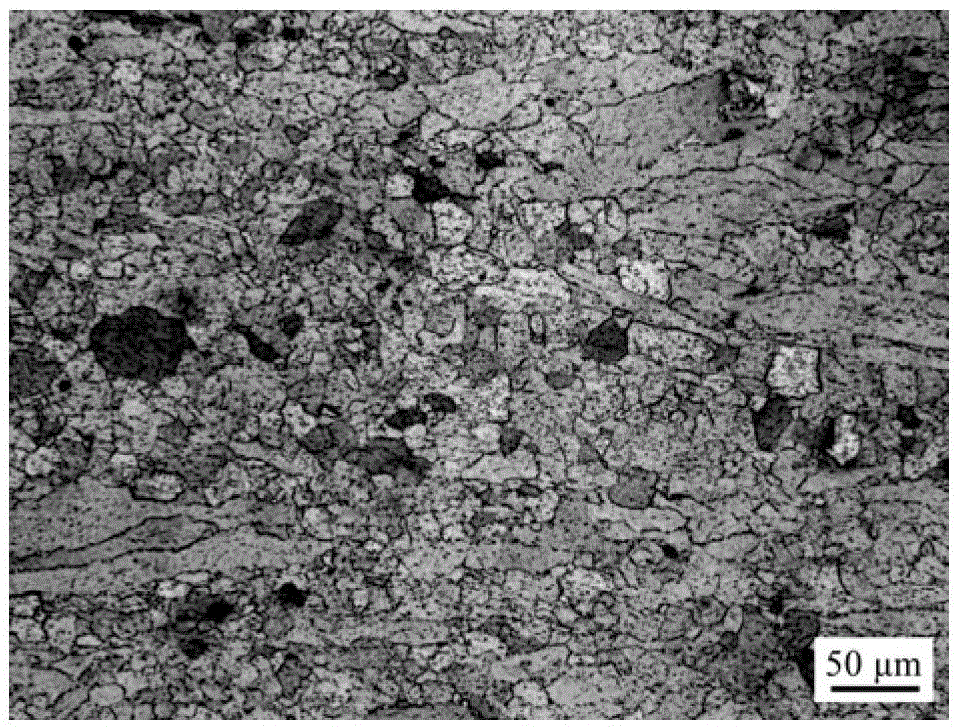

The invention relates to the technical field of metal-based composite materials, and particularly discloses a preparation method of graphene surface cobalt plating reinforced cobalt-based alloy composite powder for selective laser melting forming. According to the method, cobalt metal is uniformly loaded on the surface of graphene and the interlayer surface through an efficient, simple and convenient hydrothermal reduction method so as to improve the interface bonding condition with a matrix; the dispersity and wettability of the graphene are improved; the obtained cobalt-plated graphene serves as a reinforcing component and is mechanically ball-milled with a cobalt-based alloy; the cobalt-plated graphene and the cobalt-based alloy powder are mixed uniformly; a sample of the cobalt-plated graphene / cobalt-based composite material is printed through selective laser melting forming; then, the surface of a sample is subjected to grinding, polishing and erosion treatment and then cleaned up; and the outer surface of the erosion position is observed through a metallographic microscope. According to the method, the interface bonding strength of the graphene and the matrix can be improved, the dispersity and wettability of the graphene are improved, and the graphene reinforced cobalt-based alloy composite material with excellent performance is obtained.

Owner:ZHONGBEI UNIV

Low-temperature-resistant rubber for mower

Low-temperature-resistant rubber for a mower is prepared from the following raw materials in parts by weight: 80-120 parts of nitrile rubber, 18-30 parts of cis-polybutadiene rubber, 20-30 parts of chloroprene rubber, 6-12 parts of composite compatilizer, 20-30 parts of flame retardant, 0.4-0.8 part of anti-aging agent RD, 0.4-0.6 part of anti-aging agent MB, 10-20 parts of carbon black, 8-12 parts of zinc oxide, 2-4 parts of plasticizer DOS, and 1-2 parts of vulcanizing agent DCP. Chloroprene rubber, cis-polybutadiene rubber and nitrile rubber are matched according to a proper proportion, therefore, the rubber has good oil resistance, wear resistance and aging resistance, and also has good cold resistance, mechanical property and crack resistance. A proper vulcanizing agent is selected for crosslinking and vulcanization of the rubber for forming a cross-linked network, the mechanical property and the elasticity of the rubber are improved. The anti-aging property of the low-temperature-resistant rubber can be further improved due to the cooperation of the anti-aging agent RD and the anti-aging agent MB and rubber. The low-temperature-resistant rubber can be endowed with relativelygood extension property, tear resistance, wear resistance and elasticity through the added carbon black.

Owner:安徽屹盛机电科技有限公司

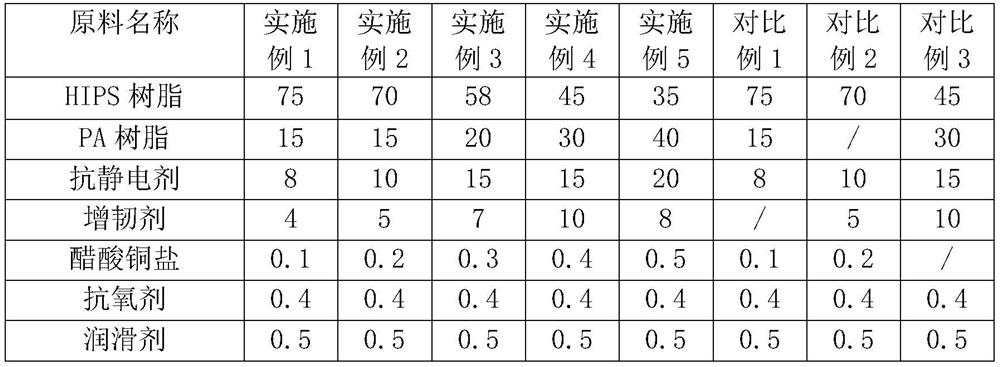

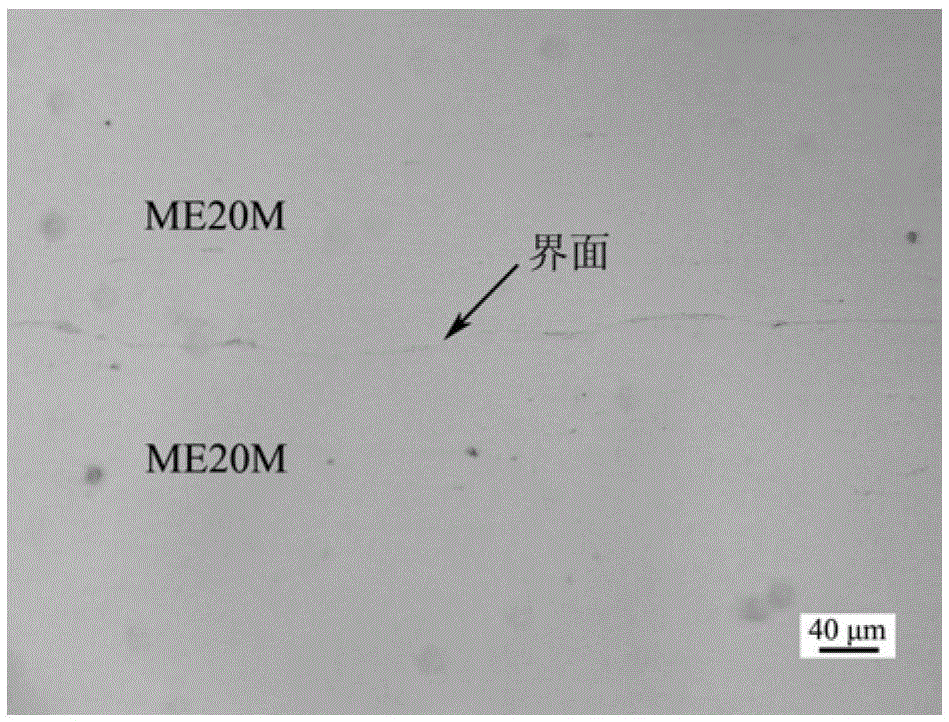

A kind of hips composite material and its preparation method and application

The invention provides a HIPS composite material and a preparation method and application thereof, comprising the following components by mass percentage: HIPS resin: HIPS resin: 35-75 parts; PA resin: 15-40 parts; antistatic agent: 8-20 parts part; copper acetate: 0.1-0.5 part; toughening agent: 4-10 part; processing aid: 0.5-1.5 part. The HIPS composite material of the invention has the characteristics of high strength, high heat resistance, antistatic and excellent barrier properties.

Owner:TIANJIN KINGFA NEW MATERIAL

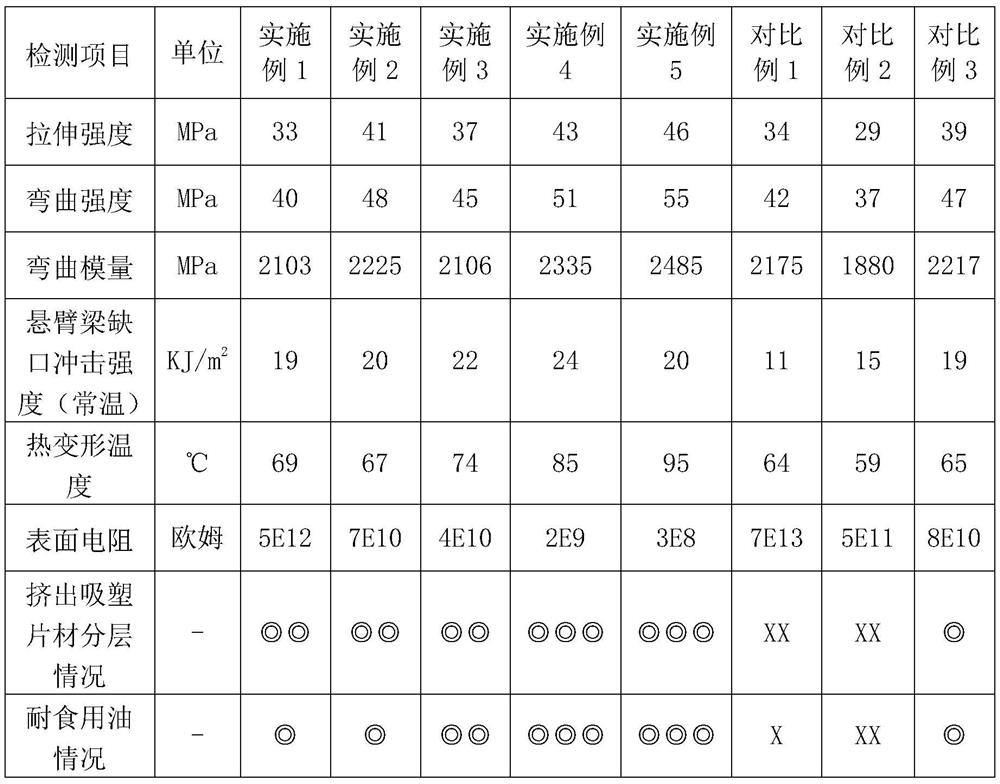

A kind of preparation method of fine-grain/ultra-fine-grain metal layered material

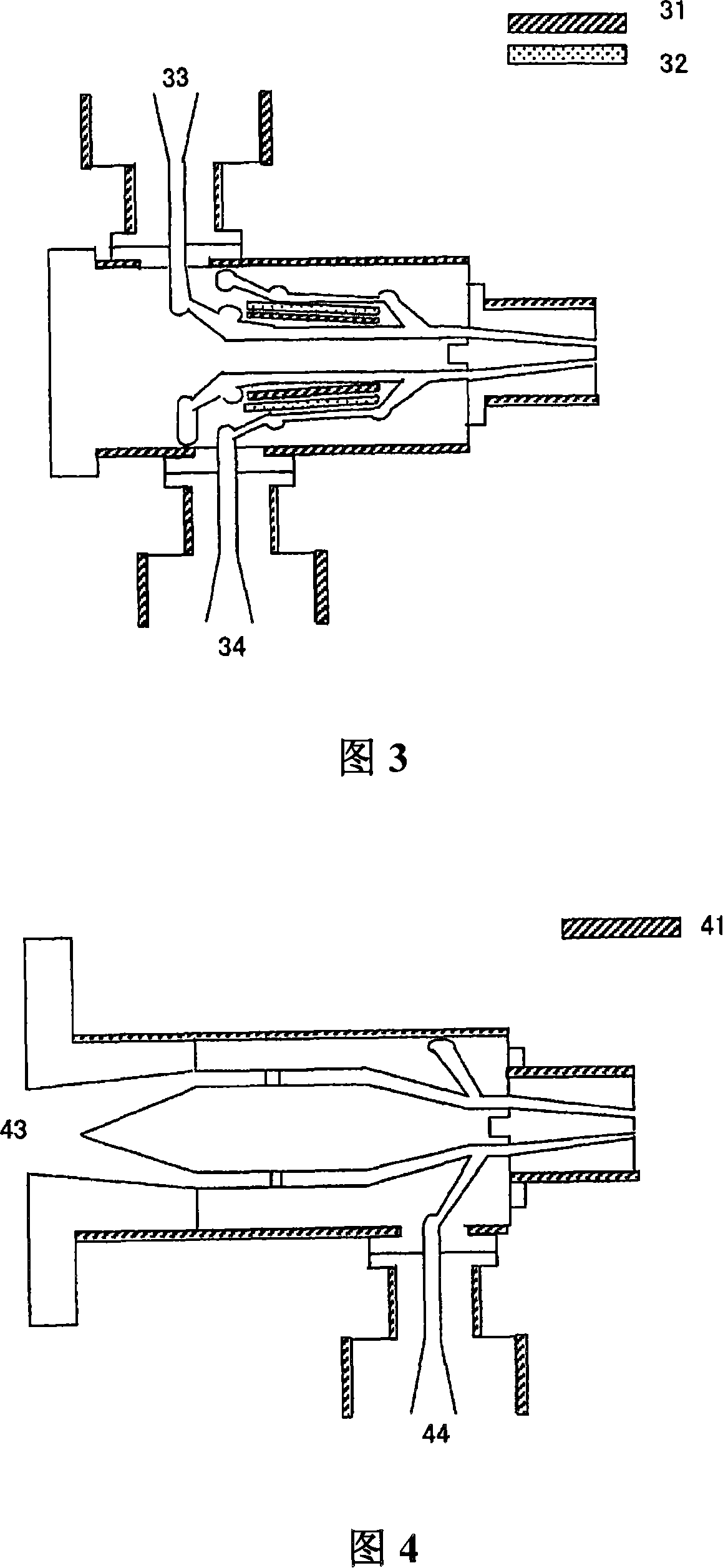

InactiveCN103394537BImprove impact resistanceImprove bending abilityExtrusion diesMetallic materialsShearing deformation

The invention discloses a preparation method of a fine-grain / ultra-fine-grain metal stratified material. The preparation method comprises the following steps of: (1) selecting n metal material samples, and preprocessing laminated faces of the metal material samples, wherein n is more than or equal to 2; and (2) laminating the metal material samples to form a combined sample, putting the combined sample into a non-equal channel angular extrusion-rolling mold, carrying out composite extrusion-rolling: applying an extrusion force to enable the combined sample to pass through a corner of the mold so that the combined sample generates shear deformation and compression deformation at the same time so as to form the fine-grain / ultra-fine-grain metal stratified material, wherein the composite extrusion-rolling is single-pass composite extrusion-rolling or multi-pass composite extrusion-rolling. By utilizing the method disclosed by the invention, the fine-grain or ultra-fine-grain metal stratified material can be prepared, and the high interface bonding strength can be achieved. The method has the characteristics of simple process, high efficiency, low device requirement and the like; and meanwhile, the material prepared by utilizing the method has good mechanical properties.

Owner:SOUTH CHINA UNIV OF TECH

A kind of preparation method of graphene and titanium alloy composite powder ball milling

The invention belongs to the field of powder titanium alloy materials, and relates to a nano material and titanium alloy composite powder preparing method, in particular to a graphene and titanium alloy composite powder ball milling preparing method. Firstly, an oxidized graphene nano sheet is added in absolute ethyl alcohol, a high-speed mechanical stirrer and an ultrasonic cell pulverizer are adopted for scattering treatment, and an oxidized graphene solution is prepared; then titanium alloy powder and the oxidized graphene solution are arranged in all-direction planet ball milling equipmentto be subjected to controlled-temperature ball milling mixing; then, obtained oxidized graphene and titanium alloy powder muddy liquid is subjected to low-speed continuous stirring till oxidized graphene and titanium alloy composite powder slurry is formed; and after drying treatment, the graphene and titanium alloy composite powder is obtained. By means of the method, good interface bonding is formed between graphene and titanium alloy powder, and dispersibility of the graphene in the titanium alloy powder is greatly improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A method for in-situ fabrication of continuous fiber reinforced soft-hard hybrid thermoplastic matrix components

ActiveCN113601835BImprove mechanical propertiesImprove interface integrationManufacturing driving meansAdditive mnaufacturing with solid and fluidComputer printingMechanical engineering

The invention discloses an in-situ manufacturing method of a continuous fiber reinforced soft-hard mixed thermoplastic base component, which includes: (1) inputting the model and process parameters required for additive manufacturing; (2) slicing the input model to obtain n layers The initial slicing path; (3) Calculate and obtain the center point P of the first layer of the slicing path c , and offset the slice path Path to P c is the coordinate system of the origin; (4) Interpolate the path of each layer to the specified precision, and the path after interpolation is Path I ; (5) Calculate Path I Arrive at the angle θ required by the nozzle's specified posture α, and readjust the Path I The start and end seams of each path, get Path end ; (6) put Path end Convert to polar coordinates to generate the printing path P of the four-axis printer x,y,z,θ , and according to the printing speed S and the nozzle control temperature T, the control code of the four-axis printer is generated. The invention solves the problems of poor mechanical properties of soft and hard mixed materials and poor interface fusion of soft and hard mixed materials.

Owner:ZHEJIANG UNIV

A Method for Preparation of Ceramic Particle Reinforced Metal Matrix Composites by Microwave-Ultrasonic Coupling

The invention discloses a method for preparing ceramic particle-reinforced metal-matrix composite materials by microwave-ultrasonic coupling. Ceramic particles, metal powder chips and organic binders are mixed and then microwave-melted, and the melted mixture is subjected to continuous microwave action. Put it in an ultrasonic field for ultrasonic treatment, and then inject the treated melt into the cavity for cooling and molding, which solves the problems of inconsistent heating, poor interface bonding ability, high energy consumption, and poor molding of ceramic particle reinforced metal matrix composites in the traditional process. Problems such as long period and uneven particle distribution, under high-power microwave radiation, ceramic particles and metal powder chips in ceramic particle reinforced metal matrix composites absorb microwaves at the same time, not only can use microwave thermal effect to achieve rapid and uniform volume heating of materials, The non-thermal effect of microwave can also be used to improve the interface bonding strength between particles and matrix to a certain extent. At the same time, ultrasonic can realize the uniform distribution of particles in the melt.

Owner:KUNMING UNIV OF SCI & TECH

A kind of preparation method of zinc oxide particle reinforced aluminum matrix composite material

ActiveCN106270509BSimple and fast operationLow costMetal rolling arrangementsZno nanoparticlesTalc / Zinc Oxide

The invention belongs to the field of composites and particularly relates to a preparation method of zinc oxide particle strengthened aluminum-based composite. Zinc oxide is ultrasonically dispersed and evenly applied between pure-aluminum plates that are subjected to full annealing, oxide film removal and degreasing, and the pure-aluminum plates are then subjected to multiple continuous accumulative rolling; a rolled sample is then subjected to discharge plasma sintering process; through strain strengthening and refined crystalline strengthening of the accumulative rolling process and particle strengthening of zinc oxide strengtheners, the composite finally produced has high microhardness about 2.1 times as high as that of an original pure-aluminum sample and also has high heat conductivity and low thermal expansion coefficient. The preparation method has low cost and good safety and reliability and is easy to perform, crystalline grains in the obtained aluminum-based nano composite structure are small, and the nano zinc oxide strengthening phase is evenly distributed with no evident clustering.

Owner:WUHAN UNIV

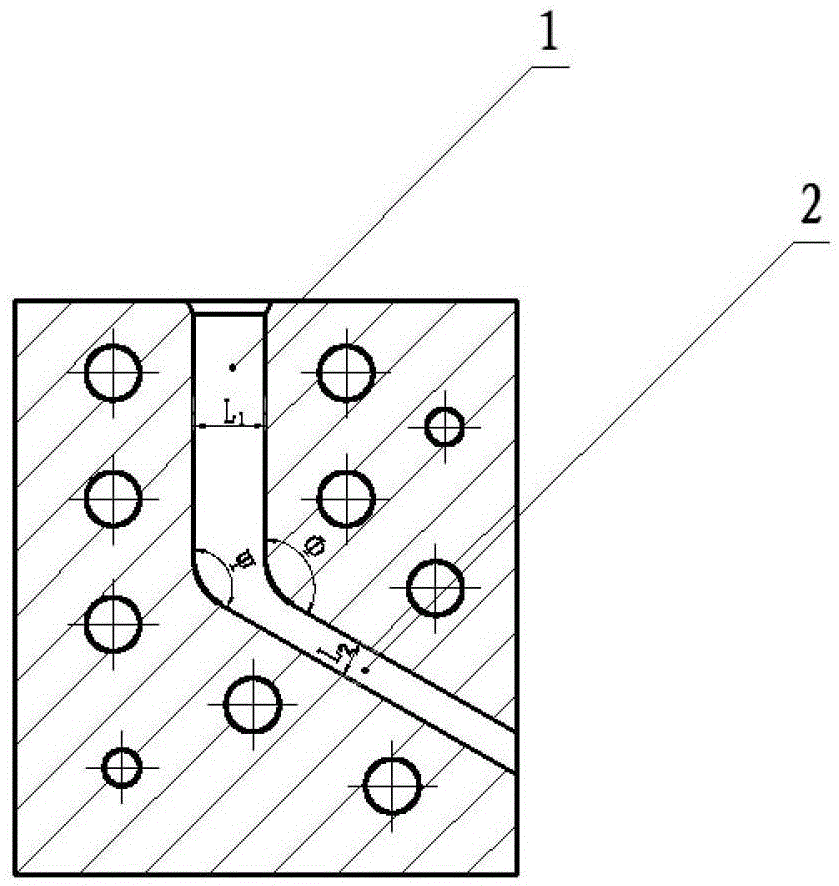

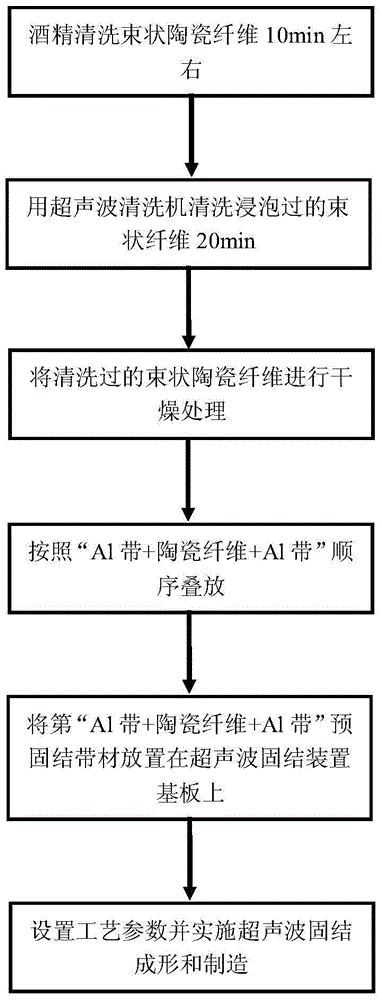

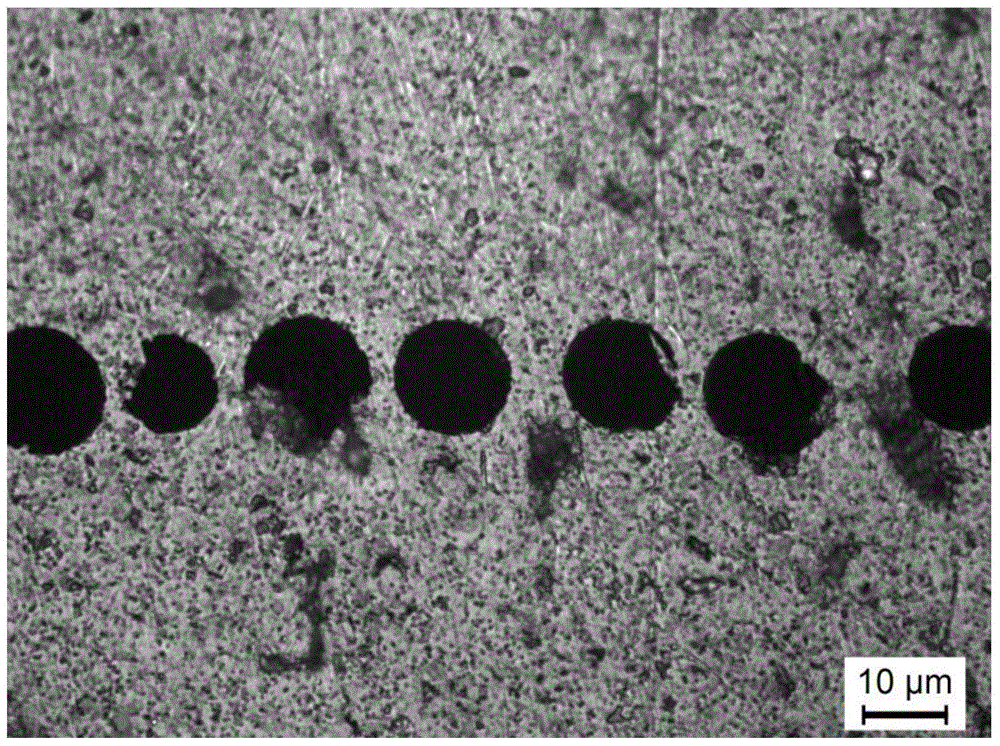

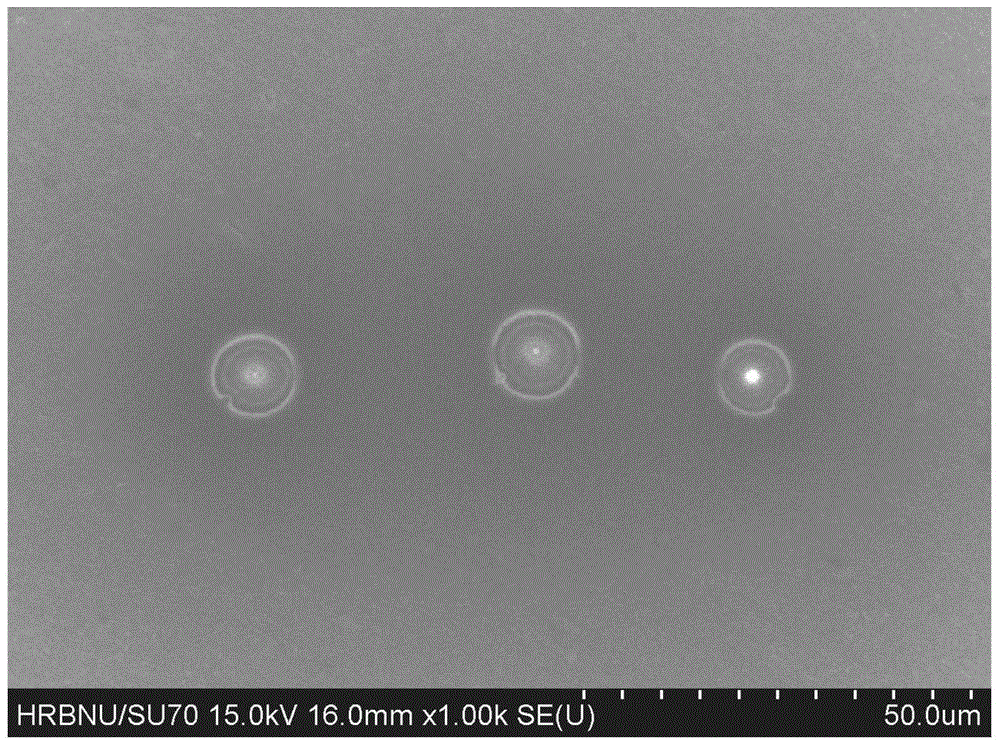

Rapid manufacturing method of ultrasonic consolidation of continuous ceramic fiber uniformly distributed aluminum strip

The invention relates to an ultrasonic consolidation rapid manufacturing method for a continuous ceramic fiber uniform-distribution aluminum strip. According to the pretreatment technological parameters of SiC ceramic fibers and Al2O3 ceramic fibers, the holding temperature ranges from 600 DEDG C to 700 DEG C, and the holding time is 1.5 h and 0.5 h. According to the manufacturing technological parameters of the pretreated bundle ceramic fiber uniform-distribution aluminum strip, at normal temperature, the added load ranges from 125 kgf to 150 kgf, the amplitude ranges from 20 microns to 40 microns, and the speed ranges from 30 mm / s to 50 mm / s. Bundle fibers in the manufactured fiber uniform-distribution aluminum strip are scattered and distributed uniformly, and are well bonded with the aluminum strip, the interface bonding situation is good, aluminum strips are bonded closely and have no obvious interface, and the rapid forming manufacturing method can be used for manufacturing the ceramic fiber uniform-distribution aluminum strip.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com