Anti-stick waterproof board and preparation method thereof

A waterproofing and anti-adhesive technology, applied in adhesives, earth-moving drilling, shaft equipment, etc., can solve the problem of difficult to explain the stable bonding performance of the self-adhesive layer, unpublished water channeling performance test data, unable to support concrete lining structure and other problems, to achieve the effects of excellent interface fusion, improved waterproof effect, and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

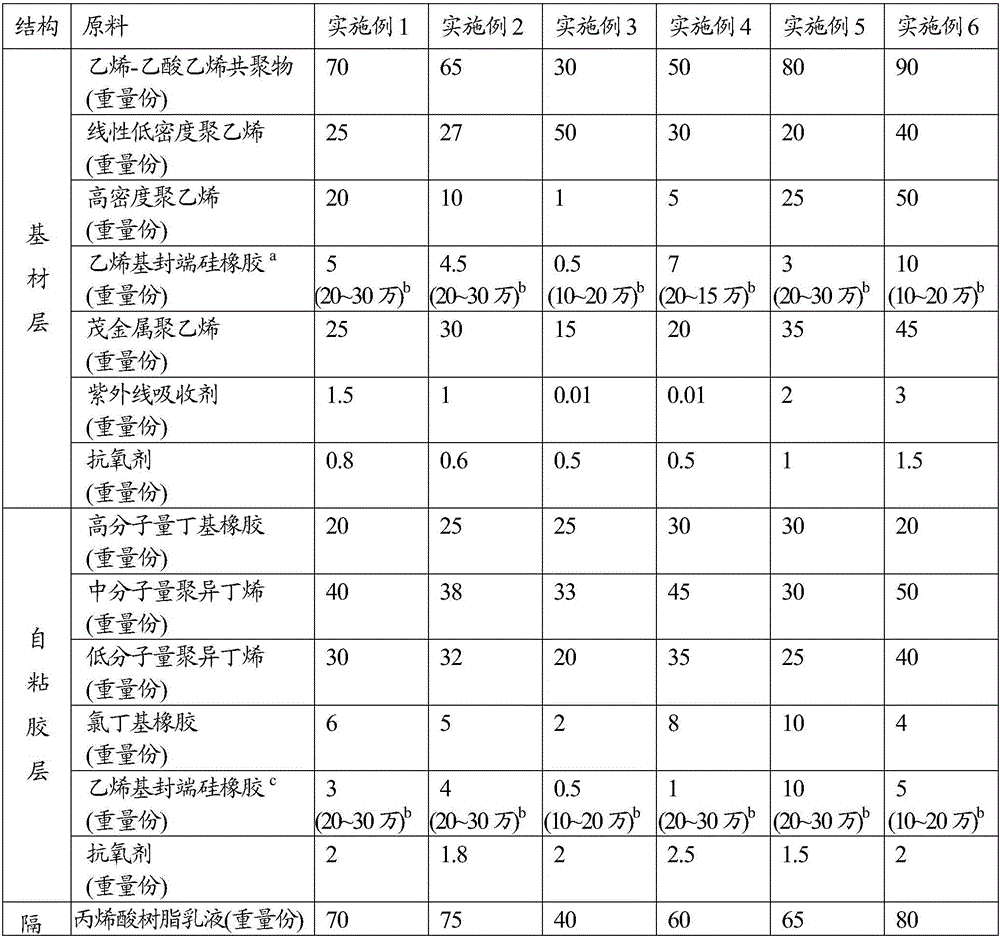

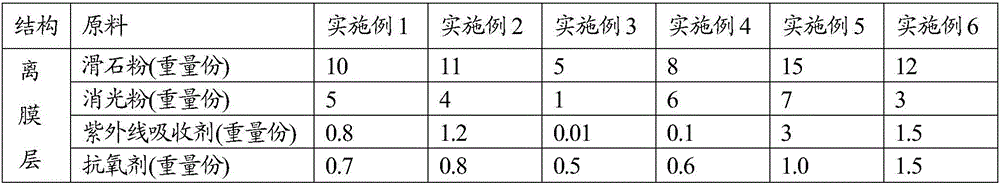

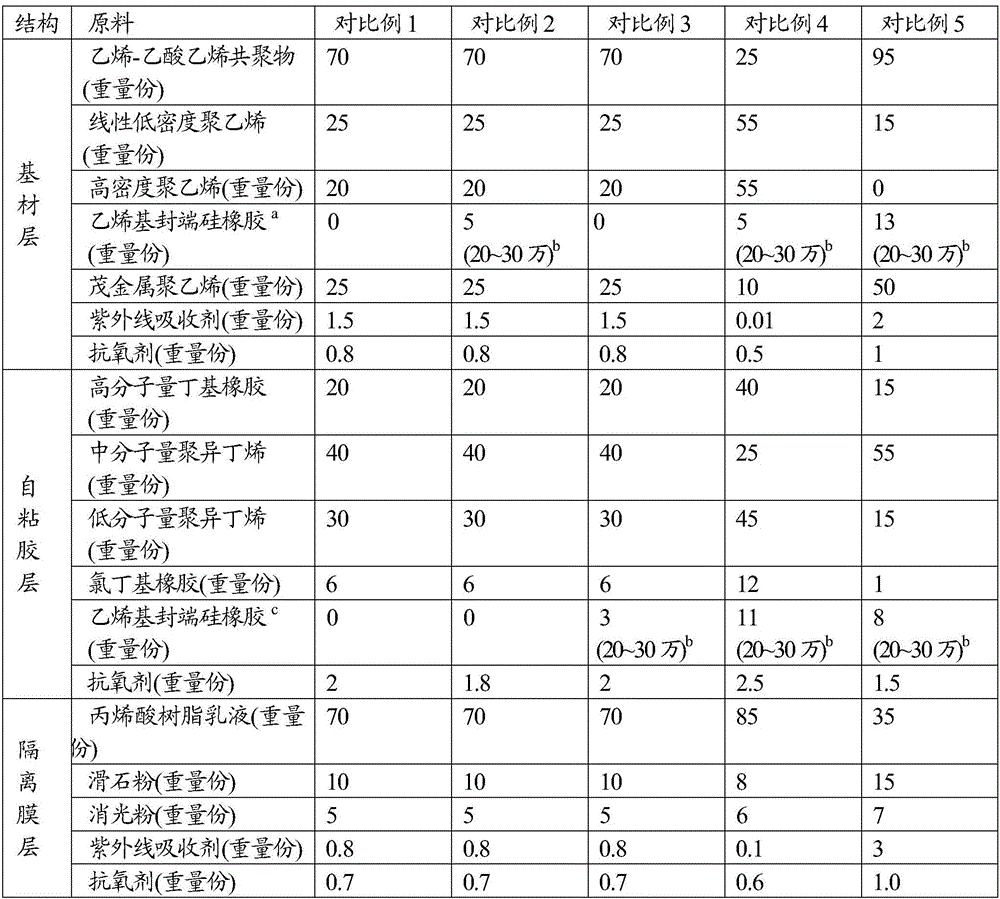

[0065] Example 1 Anti-adhesive waterproof board

[0066] An anti-adhesive waterproof board, which is composed of a substrate layer, a self-adhesive layer and an isolation film layer sequentially combined, and the self-adhesive layer is arranged between the base material layer and the isolation film layer; the base material The thicknesses of the self-adhesive layer, the self-adhesive layer and the isolation layer are 0.6-0.8mm, 0.2-0.3mm and 0.05-0.1mm respectively. See Table 1 for the raw material composition of the substrate layer, the self-adhesive layer and the isolation layer.

[0067] The above-mentioned anti-adhesive waterproof board is prepared by the following method:

[0068] I. Substrate layer extrusion calendering

[0069] Prepare each raw material according to the ratio shown in Table 1, put it into a high-speed mixer and mix evenly, transfer the mixed material to a single-screw extruder, extrude, draw, and then pass through a three-roll calender for calenderin...

Embodiment 2

[0074] Example 2 Anti-adhesive waterproof board

[0075] An anti-adhesive waterproof board, which is composed of a substrate layer, a self-adhesive layer and an isolation film layer sequentially combined, and the self-adhesive layer is arranged between the base material layer and the isolation film layer; the base material The thicknesses of the self-adhesive layer, the self-adhesive layer and the isolation layer are 0.6-0.8mm, 0.3-0.4mm and 0.10-0.15mm respectively. See Table 1 for the raw material composition of the substrate layer, the self-adhesive layer and the isolation layer.

[0076] The above-mentioned anti-adhesive waterproof board is prepared by the same method and steps as in Example 1.

Embodiment 3

[0077] Example 3 Anti-adhesive waterproof board

[0078] An anti-adhesive waterproof board, which is composed of a substrate layer, a self-adhesive layer and an isolation film layer sequentially combined, and the self-adhesive layer is arranged between the base material layer and the isolation film layer; the base material The thicknesses of the self-adhesive layer, the self-adhesive layer and the isolation layer are 0.5-0.7mm, 0.2-0.3mm and 0.05-0.1mm respectively. See Table 1 for the raw material composition of the substrate layer, the self-adhesive layer and the isolation layer.

[0079] The above-mentioned anti-adhesive waterproof board is prepared by the same method and steps as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com