A thermoplastic polymer composite material with high nail-holding force and its preparation method and application

A thermoplastic polymer and composite material technology, applied in the field of profiles, can solve the problems of poor thermal insulation effect of door and window profiles, low welding angle strength, and difficult assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

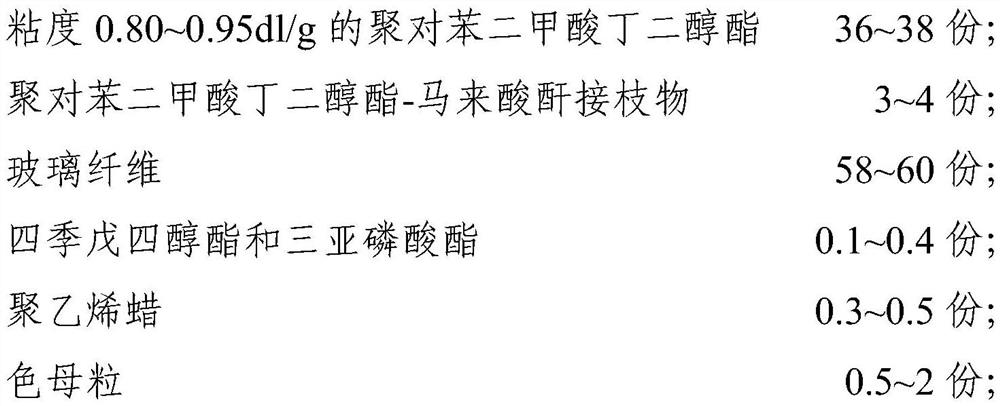

[0045] This embodiment provides a thermoplastic polymer composite material with high nail-holding force, and its preparation method comprises the following steps:

[0046] 1) 2 parts by weight (the following parts are all parts by weight) maleic anhydride (MAH) and 98 parts by weight of PBT resin with a viscosity of 0.84dl / g were mixed and stirred at high speed for 5 minutes, and then the mixture was passed through a twin-screw with a length-to-diameter ratio of 40:1 Extrude and granulate with an extruder, the extrusion temperature is 170°C-260°C, and the screw speed is 320rpm; the PBT-MAH graft is obtained; it is then dried at 120°C for 2 hours before use;

[0047]2) Dry 36 parts of PBT resin with a viscosity of 0.84dl / g at 120°C for 2-4 hours, and control the moisture content to less than 0.05%; then add 3 parts of PBT-MAH graft, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 0.5 part of color masterbatch, 0.3 part of polyethylene wax; add to the mixer and mix at...

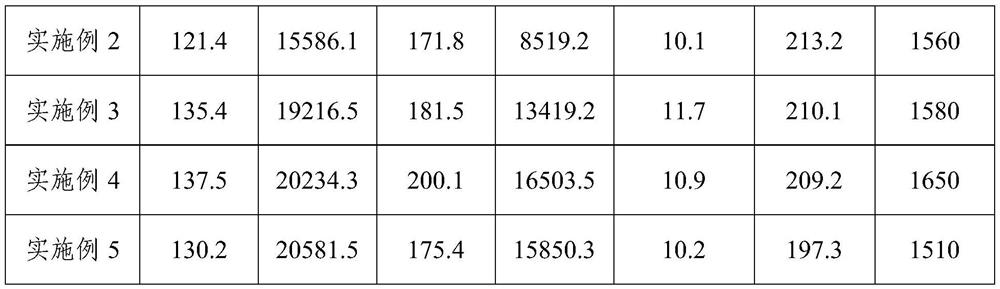

Embodiment 2

[0049] This embodiment provides a thermoplastic polymer composite material with high nail-holding force, and its preparation method comprises the following steps:

[0050] 1) 2 parts of maleic anhydride (MAH) and 98 parts of PBT resin with a viscosity of 1.05dl / g were mixed and stirred at high speed for 5 minutes, and then the mixture was extruded and granulated through a twin-screw extruder with a length-to-diameter ratio of 40:1. The temperature is 170°C-260°C, and the screw speed is 320rpm; the PBT-MAH graft is obtained; then dried at 120°C for 2 hours before use;

[0051] 2) Dry 66 parts of PBT resin with a viscosity of 1.05dl / g at 120°C for 2-4 hours, and control the moisture content to less than 0.05%; then add 3 parts of PBT-MAH graft, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 0.5 part of color masterbatch, 0.3 part of polyethylene wax; add to the mixer and mix at high speed for 5-10 minutes, and enter the twin-screw extruder from the metering feeder. ...

Embodiment 3

[0053] This embodiment provides a thermoplastic polymer composite material with high nail-holding force, and its preparation method comprises the following steps:

[0054] 1) 2 parts of maleic anhydride (MAH) and 98 parts of PBT resin with a viscosity of 0.90dl / g were mixed and stirred at high speed for 5 minutes, and then the mixture was extruded and granulated through a twin-screw extruder with a length-to-diameter ratio of 40:1. The temperature is 170°C-260°C, and the screw speed is 320rpm; the PBT-MAH graft is obtained; then dried at 120°C for 2 hours before use;

[0055] 2) Dry 51 parts of PBT resin with a viscosity of 0.90dl / g at 120°C for 2-4 hours, and control the moisture content to less than 0.05%; then add 3 parts of PBT-MAH graft, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 0.5 part of color masterbatch, 0.3 part of polyethylene wax; add to the mixer and mix at high speed for 5-10 minutes, and enter the twin-screw extruder from the metering feeder. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| nail holding power | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| nail holding power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com