Special impact-resistant polystyrene material for new-energy vehicles and preparation method of material

A technology of new energy vehicles and polystyrene, which is applied in the field of polymer materials, can solve the problems of low impact performance of impact polystyrene resin, improve bending strength and heat resistance of impact strength, improve impact resistance, The effect of increasing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

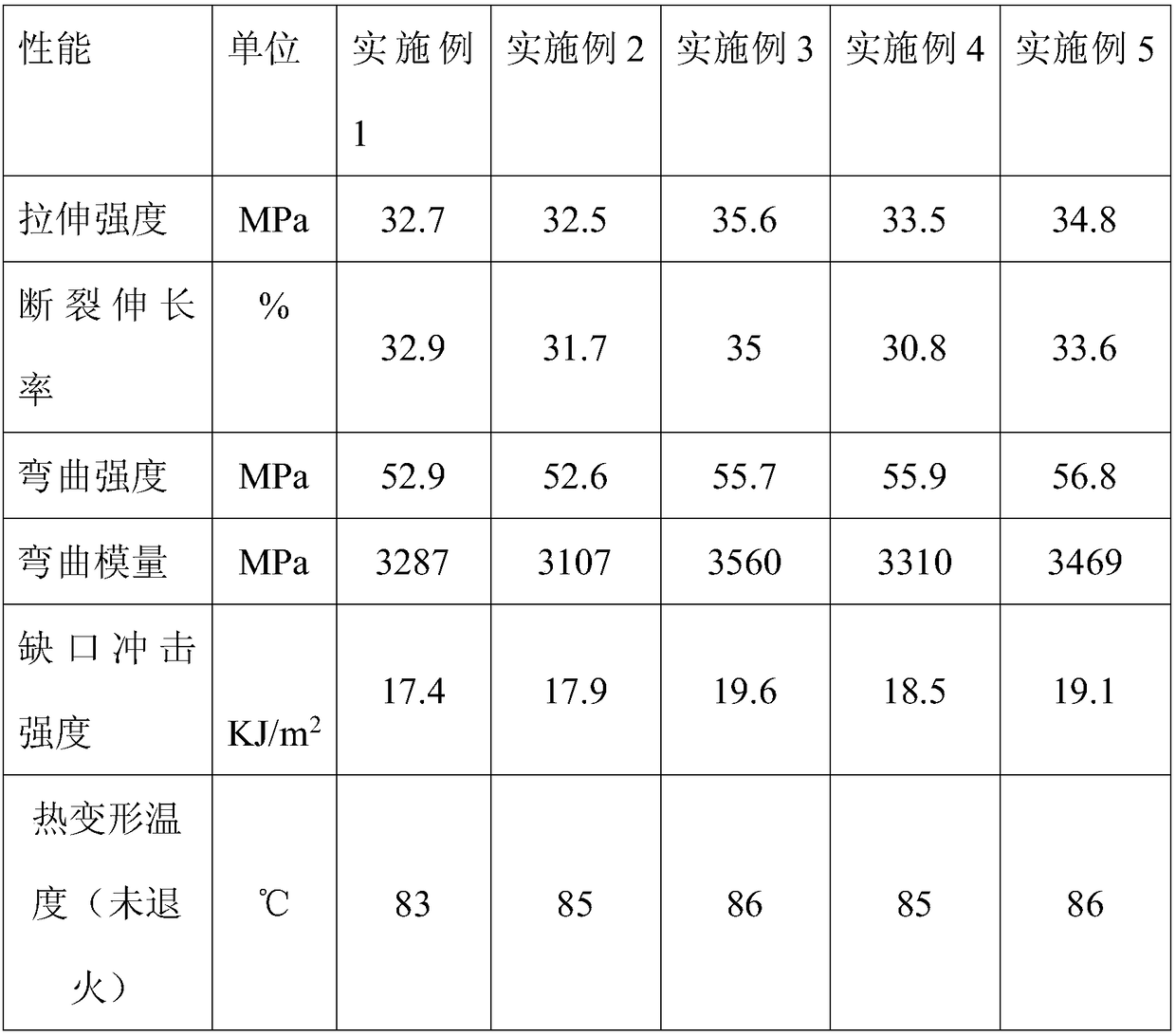

Examples

Embodiment 1

[0024] The impact-resistant polystyrene material specially used for new energy vehicles in this embodiment is made of the following raw materials by weight: 50 parts of high-impact polystyrene resin, 30 parts of acrylated epoxy resin, 25 parts of polyurethane elastomer, modified 10 parts of fiber, 10 parts of graphene oxide, 10 parts of nano-talc, 2 parts of triphenyl phosphate, 1 part of isophorone diisocyanate, 1 part of tris(2,4-di-tert-butylphenyl) phosphite , 1 part of silicone oil, 1 part of plasticizer, 1 part of toughening agent;

[0025] Wherein, the modification method of the modified fiber is as follows: weighing 1.5 parts of silane coupling agent, 8 parts of absolute ethanol, and 15 parts of fibers by weight, mixing the silane coupling agent with absolute ethanol, adding fibers, and ultrasonically dispersing After treatment for 30min, mechanical stirring was carried out for 1h, then the pH range was adjusted to 4 with HCl, the reaction temperature was adjusted to 5...

Embodiment 2

[0031] The impact-resistant polystyrene material specially used for new energy vehicles in this embodiment is made of the following raw materials by weight: 90 parts of high-impact polystyrene resin, 70 parts of acrylated epoxy resin, 55 parts of polyurethane elastomer, modified 16 parts of fiber, 16 parts of graphene oxide, 16 parts of nano-talc, 6 parts of triphenyl phosphate, 4 parts of isophorone diisocyanate, 4 parts of tris(2,4-di-tert-butylphenyl) phosphite , 5 parts of silicone oil, 3 parts of plasticizer, 4 parts of toughening agent;

[0032] Wherein, the modification method of the modified fiber is as follows: weighing 2 parts of silane coupling agent, 15 parts of absolute ethanol, and 30 parts of fibers according to parts by weight, mixing the silane coupling agent with absolute ethanol, adding fibers, and ultrasonically dispersing After treatment for 50min, mechanical stirring was performed for 3h, then the pH range was adjusted to 5 with HCl, the reaction temperat...

Embodiment 3

[0038] The impact-resistant polystyrene material specially used for new energy vehicles in this embodiment is made of the following raw materials by weight: 70 parts of high-impact polystyrene resin, 50 parts of acrylated epoxy resin, 40 parts of polyurethane elastomer, modified 13 parts of fiber, 13 parts of graphene oxide, 13 parts of nano-talc, 4 parts of triphenyl phosphate, 2.5 parts of isophorone diisocyanate, 2.5 parts of tris(2,4-di-tert-butylphenyl) phosphite , 3 parts of silicone oil, 2 parts of plasticizer, 2.5 parts of toughening agent;

[0039] Wherein, the modification method of the modified fiber is as follows: weighing 2.2 parts of silane coupling agent, 11 parts of absolute ethanol, and 23 parts of fibers by weight, mixing the silane coupling agent with absolute ethanol, adding fibers, and ultrasonically dispersing Treat for 40min, then mechanically stir for 2h, then adjust the pH range to 4-5 with HCl, adjust the reaction temperature to 58°C, and ultrasonical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com