A kind of low VOC natural fiber composite material, preparation method and application thereof

A natural fiber and composite material technology, applied in the field of fiber composite materials, can solve the problems of weakened VOC adsorption capacity, endangering the health of people in the car, and increasing production costs, so as to reduce VOC release, improve interface bonding, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

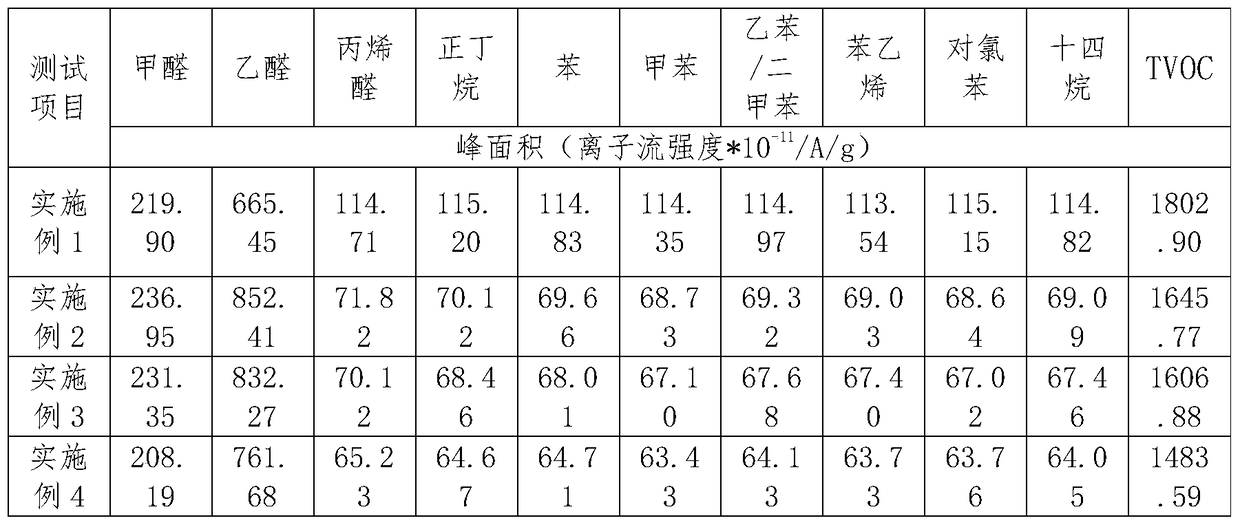

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of low-VOC natural fiber composite material, described method comprises following process step:

[0021] Step S1, spraying the VOC capture agent on the mixed fibers of the opened natural fibers and polypropylene fibers.

[0022] In this step, a predetermined proportion of natural fibers and polypropylene fibers are first mixed to form mixed fibers of natural fibers and polypropylene fibers, and the mixed fibers of natural fibers and polypropylene fibers are opened, and then after opening Spray VOC capture agent on the mixed fiber of natural fiber and polypropylene fiber.

[0023] In the present invention, the natural fiber adopted can be one or more mixtures of hemp, jute, flax, ramie, kenaf, cotton, kapok fiber and sisal fiber. The VOC trapping agent used can be one or more of the following: polyvinyl alcohol solution and urea solution, etc. The polyvinyl alcohol solution is prepared by stirring polyvinyl alcohol an...

no. 1 approach

[0033]Take 50g of untreated natural fibers and 50g of polypropylene fibers, open, card, and needle-punching processes to make fiber mats, and then prepare composite materials through hot-pressing processes.

no. 2 approach

[0035] Take 1g of polyvinyl alcohol and 9ml of water into a mechanical stirrer, and stir at 400r / min at 90°C for 1h.

[0036] Take 50g of natural fiber and 50g of polypropylene fiber, mix and open the two fibers, spray the prepared polyvinyl alcohol solution on the opened mixed fiber, comb and needle punch to make a fiber mat, and then heat press process to prepare composite materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com